Metal Mickey

Well-Known Member

- Joined

- Jul 5, 2008

- Messages

- 612

- Reaction score

- 6

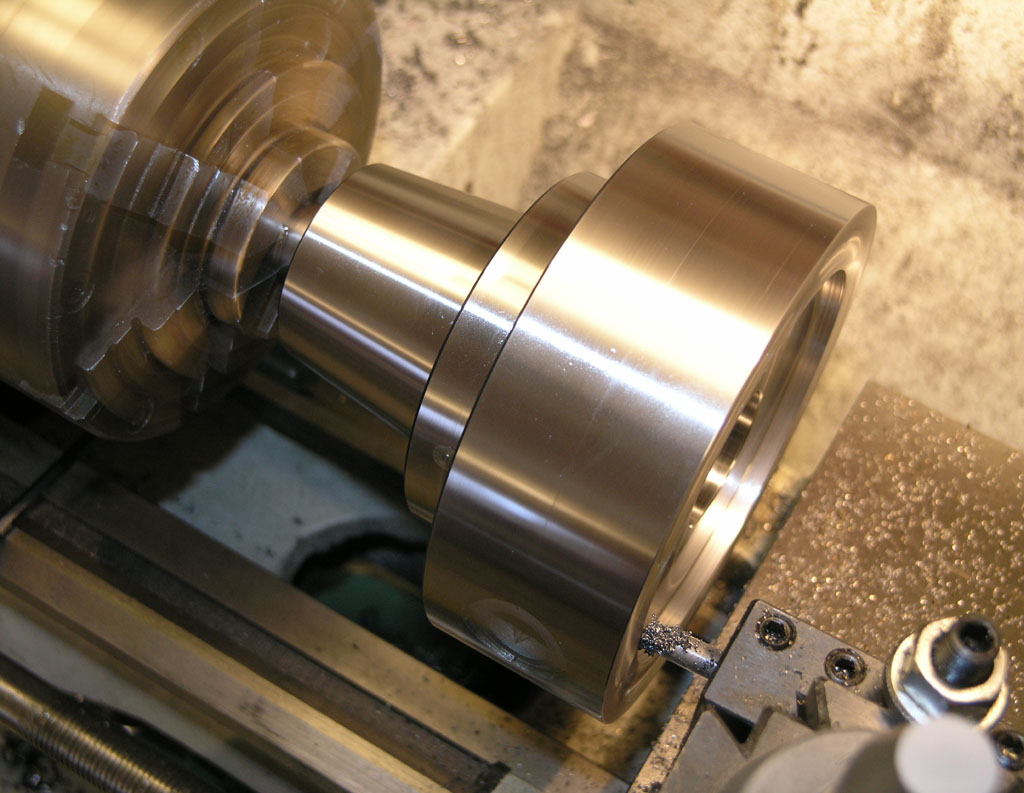

Since refurbishing my Myford ML7 I have learnt not to trust tooling and now measure everything (including finding the toolpost on my nearly new tailstock out of true) so when a new ER25 collet chuck from a well know UK tool supplier I tested it for running true with a stainless steel bar in the collet.

It came out with a 0.008" variation. I thought at first it may be the bar but I started and put the dial indicator on the nose of the ML7, which was fine. I then tested the finished outside of the chuck itself and that was running true! SO I thought that I would test the inside of the chuck and it repeated the error (less a thou) found on the bar.

So if the outside of the chuck runs true and the inside doesn't to what I think is a significant and unacceptable amount (say 0.007" to be fair). Before I phone the supplier on Monday I thought I would ask members here for your views. Is that amount of runout acceptable or no. If no, what would be acceptable.

Many thanks. MM

It came out with a 0.008" variation. I thought at first it may be the bar but I started and put the dial indicator on the nose of the ML7, which was fine. I then tested the finished outside of the chuck itself and that was running true! SO I thought that I would test the inside of the chuck and it repeated the error (less a thou) found on the bar.

So if the outside of the chuck runs true and the inside doesn't to what I think is a significant and unacceptable amount (say 0.007" to be fair). Before I phone the supplier on Monday I thought I would ask members here for your views. Is that amount of runout acceptable or no. If no, what would be acceptable.

Many thanks. MM