Maryak

Well-Known Member

- Joined

- Sep 12, 2008

- Messages

- 4,990

- Reaction score

- 77

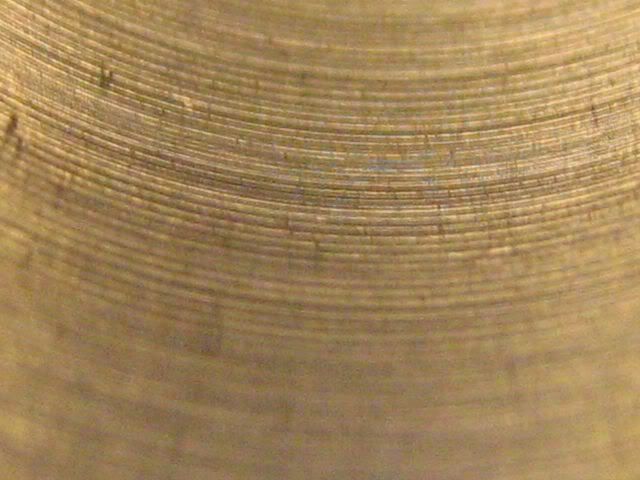

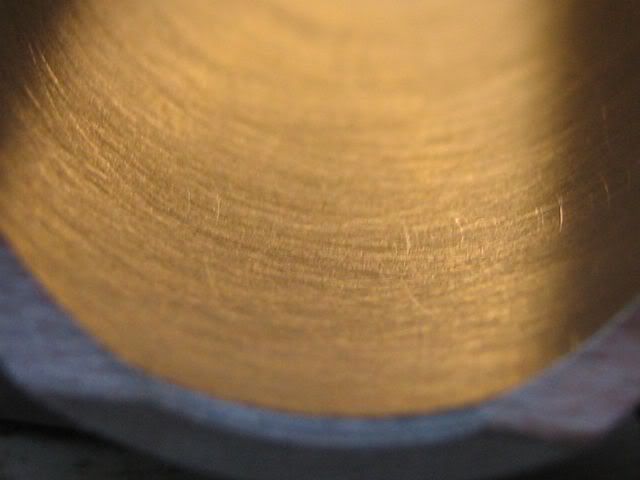

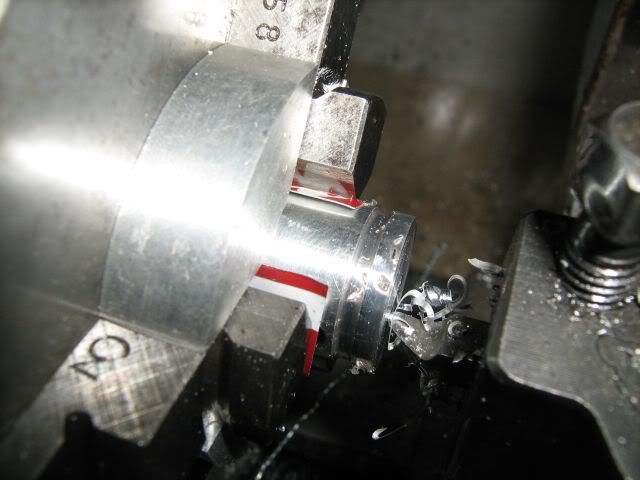

Mo deller said:My other concern is bell mouthing. My feeling is that I should proceed with the bottom of the cylinder towards the chuck and not take the top past the cutting area of the lap but just up too it.

Or would that be opposite and actually cause more to be taken at the top? ???

Any thoughts?

Thanks,

Peter.

Pete,

Oddly enough the bulge in the lap created by the wedge actually helps to achieve a parallel bore as in micro terms more metal is removed in the centre where the bulge is. A slight taper of 0.0005" is said to help as long as the smaller size is at the top where the contra piston is located. Personally having built 2 of this type of engine a good finish and mate between piston and bore is most important and a tighter fit than you would think for the contra piston are the keys to success. The final mate of piston and cylinder using tallow is also very well worth doing.

Best Regards

Bob