You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Two IC newbies Build Websters

- Thread starter jixxerbill

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

aonemarine

Well-Known Member

- Joined

- Nov 18, 2012

- Messages

- 887

- Reaction score

- 212

OK, well I guess bill is long lost and im wanting to start another project but I cant bring myself to do that until I finish this one up. So tomorrow Im going to try to find the top of the work bench, get my butt back in gear, finish up a couple straggleing jobs and get this puppy running.

Cheepo45, ill never pick on you for how long it takes you to build an engine again! LOL

Cheepo45, ill never pick on you for how long it takes you to build an engine again! LOL

aonemarine

Well-Known Member

- Joined

- Nov 18, 2012

- Messages

- 887

- Reaction score

- 212

cheepo45

Member

- Joined

- Dec 22, 2010

- Messages

- 278

- Reaction score

- 131

I'm sure a lot of us have other interests and responsibilities that take precedence over our model building activities. I do tend to jump from interest to interest a lot (ocd?). Seeing my latest creation start and run was pretty cool. The cold winter helped a lot, too.

Keep building!

cheepo45

Keep building!

cheepo45

- Joined

- May 27, 2010

- Messages

- 2,999

- Reaction score

- 1,171

Hi there.

Making very good progress and soon we can see the engines running. Meanwhile I am taking my sweet time building the Howell V-2.

Making very good progress and soon we can see the engines running. Meanwhile I am taking my sweet time building the Howell V-2.

Websters, Websters, everywhere! Looks like there are at least three active threads on Websters right now.

Just spent some time catching up on this thread - some very nice work going on. Always nice to see how others tackle a job. I had my Webster on the back burner for a while, but got back into it a couple of weeks ago and so far, so good.

Looking forward to see more in this thread.

Just spent some time catching up on this thread - some very nice work going on. Always nice to see how others tackle a job. I had my Webster on the back burner for a while, but got back into it a couple of weeks ago and so far, so good.

Looking forward to see more in this thread.

theonlybigchief

New Member

- Joined

- Feb 27, 2015

- Messages

- 1

- Reaction score

- 1

Hi fellas,

When I built my Webster, I didn't (couldn't bring myself) to cut the big notch from the base. I'm glad I didn't. I always had a question in the back of my mind where was I going to mount a gas tank. I'm glad I didn't cut the notch because that is where I ended up mounting it. See attachment

When I built my Webster, I didn't (couldn't bring myself) to cut the big notch from the base. I'm glad I didn't. I always had a question in the back of my mind where was I going to mount a gas tank. I'm glad I didn't cut the notch because that is where I ended up mounting it. See attachment

aonemarine

Well-Known Member

- Joined

- Nov 18, 2012

- Messages

- 887

- Reaction score

- 212

Yea, Im kind wishin I hadnt cut the notch out  oh well too late now....

oh well too late now....

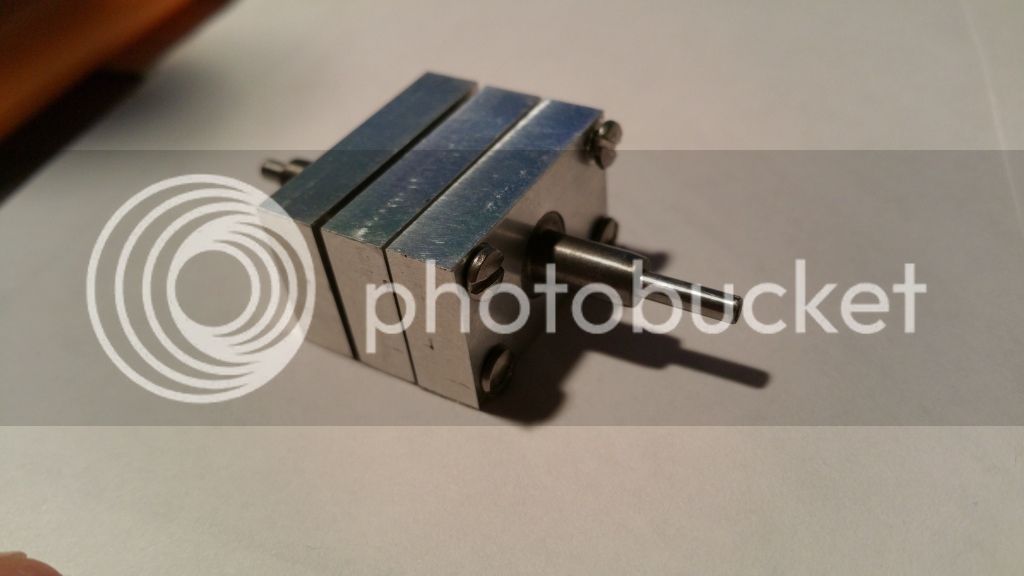

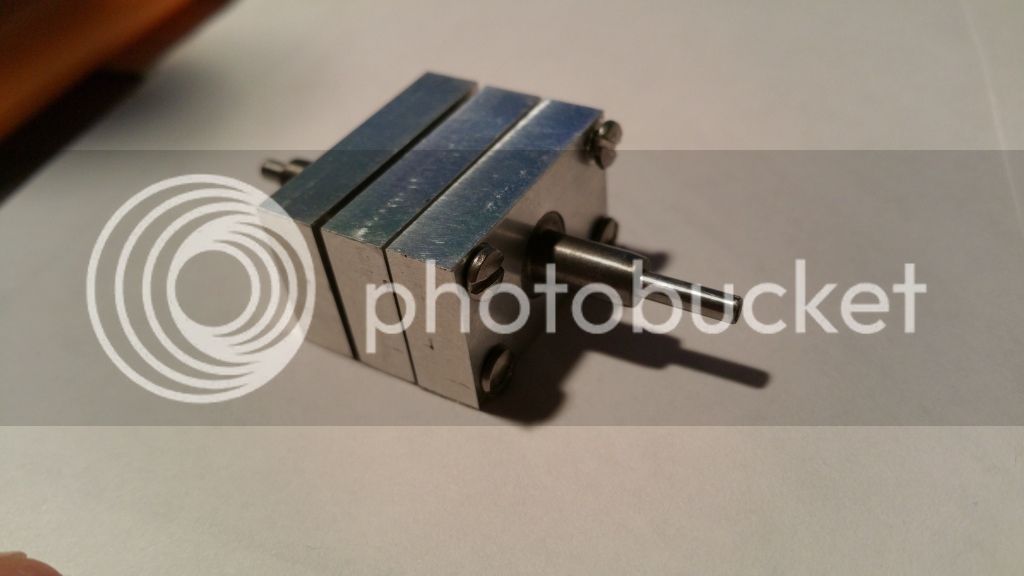

Did some playing with the cnc mill and worked on finishing off the valve chest thingie, just a couple more holes to drill. Still learning how to use the cam software but having more computer time than shop time it works out well for me. I was pretty impressed with the press fit of the guides into the valve chest since they were sprial cut with a end mill and not drilled and reamed, although I need to buy a chamfer mill to break the edge where the flanged part of the seat sits as i didnt get a perfectly square corner on the guide when I turned it in the lathe.

Did some playing with the cnc mill and worked on finishing off the valve chest thingie, just a couple more holes to drill. Still learning how to use the cam software but having more computer time than shop time it works out well for me. I was pretty impressed with the press fit of the guides into the valve chest since they were sprial cut with a end mill and not drilled and reamed, although I need to buy a chamfer mill to break the edge where the flanged part of the seat sits as i didnt get a perfectly square corner on the guide when I turned it in the lathe.

Similar threads

- Replies

- 57

- Views

- 9K