GWRdriver

Senior Member

- Joined

- Jan 22, 2009

- Messages

- 721

- Reaction score

- 109

Brian,

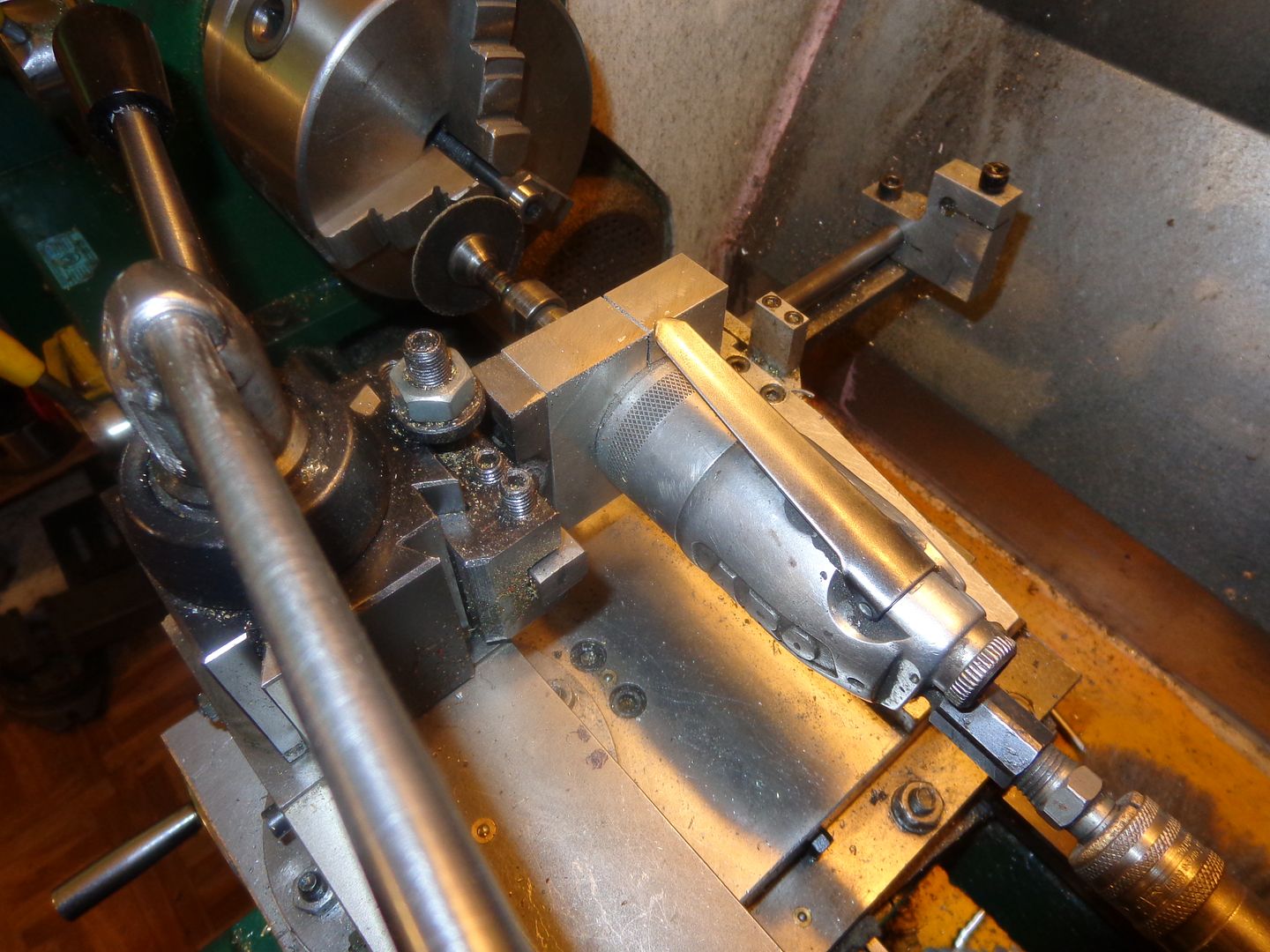

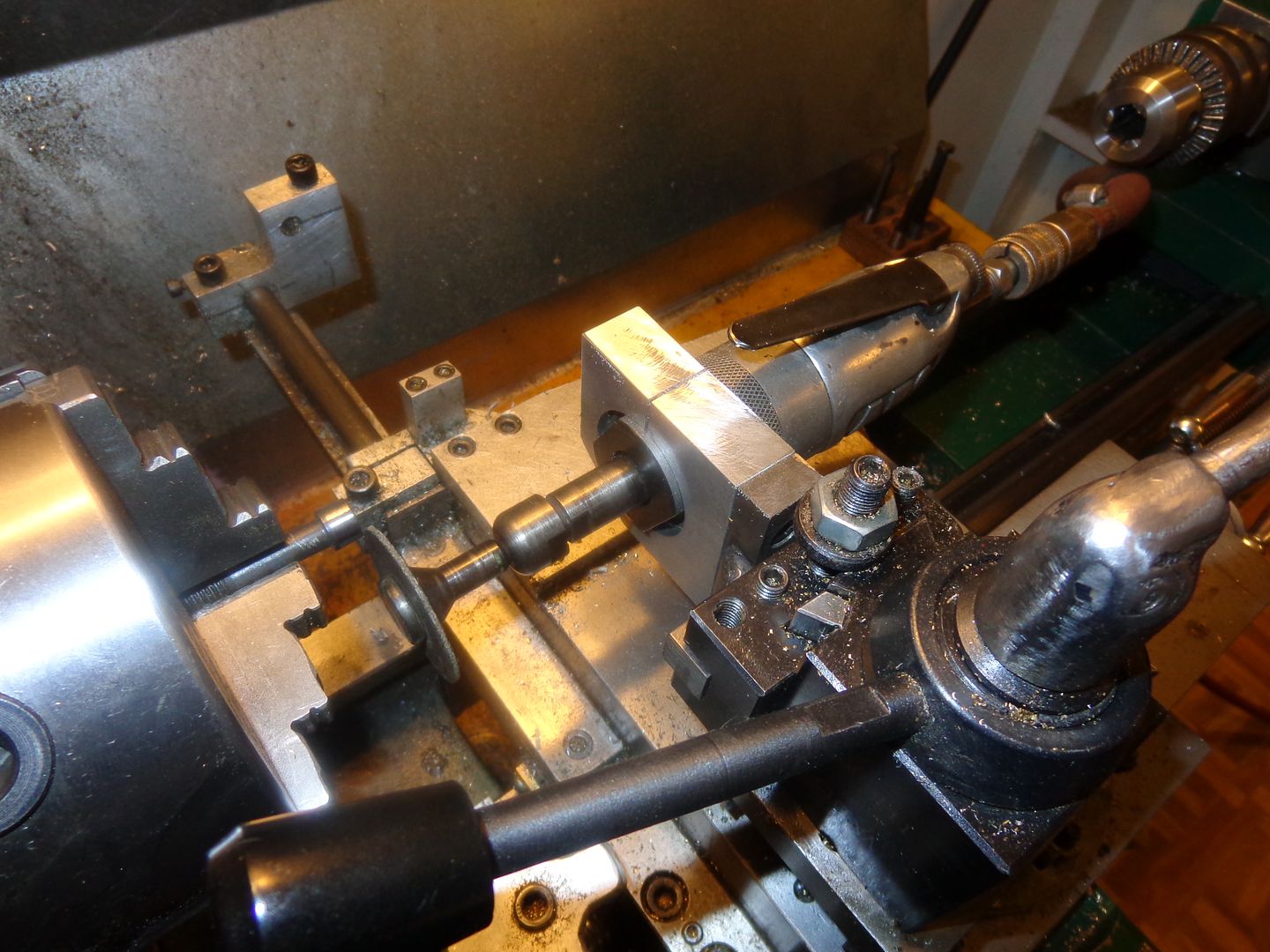

I just now tuned in and had I arrived sooner would have reported that this scheme never worked for me. I have to qualify my statement by saying that what I wanted to achieve was a substitute toolpost grinder and even the best Dremel or Dremel-clone tools (specifically their bearings) aren't up to the job. The reason is just as you have discovered, there is too much flex and runout in the cheap spindle.

I'm not exactly sure what you need to accomplish - is this a shaping operation or a finishing operation? If it's a shaping (ie, turning) operation and what you need is increased spindle speed I would start to think in terms of an accessory spindle which would mount in your lathe spindle nose and be driven by a small high speed motor & belt.

Tell me more before I wander way off course.

I just now tuned in and had I arrived sooner would have reported that this scheme never worked for me. I have to qualify my statement by saying that what I wanted to achieve was a substitute toolpost grinder and even the best Dremel or Dremel-clone tools (specifically their bearings) aren't up to the job. The reason is just as you have discovered, there is too much flex and runout in the cheap spindle.

I'm not exactly sure what you need to accomplish - is this a shaping operation or a finishing operation? If it's a shaping (ie, turning) operation and what you need is increased spindle speed I would start to think in terms of an accessory spindle which would mount in your lathe spindle nose and be driven by a small high speed motor & belt.

Tell me more before I wander way off course.