mklotz

Well-Known Member

I've wanted for a long time to build a Thermal Lag Engine (TLE). I have a physicist's fascination with heat engines and the TLE is even simpler in conformation than the conventional or Ringbom Stirlings. I just "hadda have one".

I got a copy of Jan Ridder's plans and some other information from the web including the original patent for this type of engine. It quickly became apparent that, just as with most everything, the size of test tubes is not standardized. The ones in my collection (left over from building a perfusion machine in high school - a story for another time) aren't anything like Jan's. Moreover, all of these plans admit that a certain amount of fiddling with the design will be necessary. The engine isn't well enough understood to allow for theortetical models of all the "fiddling" parameters so designing in the conventional sense isn't possible.

So, just like any good systems engineer would do, I decided to build a Proof-of-Concept (POC) engine to see if I could get anything to run and, if so, be able to easily fiddle with all the parameters to get a handle on what mattered. Once the POC works, I should know more about what I'm doing and can then go on to build a proper engine.

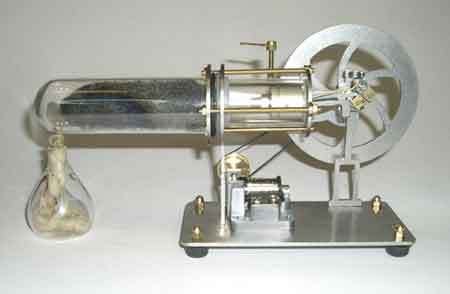

The video shows the engine. It's nothing more than a test tube with an aluminum cylinder attached via a spigot. The spigot is fitted with two O-rings that seal the test tube to the cylinder. A (critical) aperture in the spigot allows the cylinder to communicate with the test tube. Inside the cylinder is a (critical) lump of stainless steel pot scrubber that acts as a regenerator, although I'll freely admit to not completely understanding what a regenerator accomplishes in that location - I think it's more of a heat retention device.

Inside the cylinder is a graphite piston which connects to a flywheel via a conventional crank. The bits and pieces are temporarily cobbled together on a fixture plate and various setscrews allow nearly every dimension to be adjusted. I had intended to fit the aperture with a means of inserting various size orifices but I lucked out and my first guess produced a working POC. I may yet go back and do that to see if I can further optimize the performance.

And that's it... no valves, no displacer. Just a piston in a closed cylinder. The test tube is heated at the end of the regenerator via an external heat source (alcohol lamp in my case) and the damn thing runs! I don't have time right now to discuss why it works but it's basically the Otto cycle - the working fluid (air) is compressed at a lower temperature, heated, and then expands at a higher temperature. If you plot that on a P-V diagram you'll see that the closed cycle has a net area and that area corresponds to the work done on the flywheel.

If you decide to build a TLE, I strongly suggest that you build a POC first. These engines have very low specific power and thus are sensitive to friction as well as their innate sensitivity to the overall geometry of the engine.

[ame]http://www.youtube.com/watch?v=3DF9gNCavKs[/ame]

I got a copy of Jan Ridder's plans and some other information from the web including the original patent for this type of engine. It quickly became apparent that, just as with most everything, the size of test tubes is not standardized. The ones in my collection (left over from building a perfusion machine in high school - a story for another time) aren't anything like Jan's. Moreover, all of these plans admit that a certain amount of fiddling with the design will be necessary. The engine isn't well enough understood to allow for theortetical models of all the "fiddling" parameters so designing in the conventional sense isn't possible.

So, just like any good systems engineer would do, I decided to build a Proof-of-Concept (POC) engine to see if I could get anything to run and, if so, be able to easily fiddle with all the parameters to get a handle on what mattered. Once the POC works, I should know more about what I'm doing and can then go on to build a proper engine.

The video shows the engine. It's nothing more than a test tube with an aluminum cylinder attached via a spigot. The spigot is fitted with two O-rings that seal the test tube to the cylinder. A (critical) aperture in the spigot allows the cylinder to communicate with the test tube. Inside the cylinder is a (critical) lump of stainless steel pot scrubber that acts as a regenerator, although I'll freely admit to not completely understanding what a regenerator accomplishes in that location - I think it's more of a heat retention device.

Inside the cylinder is a graphite piston which connects to a flywheel via a conventional crank. The bits and pieces are temporarily cobbled together on a fixture plate and various setscrews allow nearly every dimension to be adjusted. I had intended to fit the aperture with a means of inserting various size orifices but I lucked out and my first guess produced a working POC. I may yet go back and do that to see if I can further optimize the performance.

And that's it... no valves, no displacer. Just a piston in a closed cylinder. The test tube is heated at the end of the regenerator via an external heat source (alcohol lamp in my case) and the damn thing runs! I don't have time right now to discuss why it works but it's basically the Otto cycle - the working fluid (air) is compressed at a lower temperature, heated, and then expands at a higher temperature. If you plot that on a P-V diagram you'll see that the closed cycle has a net area and that area corresponds to the work done on the flywheel.

If you decide to build a TLE, I strongly suggest that you build a POC first. These engines have very low specific power and thus are sensitive to friction as well as their innate sensitivity to the overall geometry of the engine.

[ame]http://www.youtube.com/watch?v=3DF9gNCavKs[/ame]