That should work fine but I doubt you will really want to grind the base so you can use 5/8" bits. You will probably be using 3/8" bits with a 3/16" shim under them on a 9" lathe. I had a mate for that tool holder on a 10" South Bend before I changed to a Aloris type tool holder.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The Boxford Files

- Thread starter CrewCab

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Guys thanks for all the help :bow:

Given a little time I will upgrade it to a qctp, I've got one on the 9" x 20" with about a dozen holders, but it's a nad's small for the Boxford, and in the short term that has to stay in place so .........

........... I'm looking for something to use ........... John, I don't have any facilities for surface grinding so I'll take it as comes if that's OK .......... thanks.

Stan / Dave ............ is The sort you mean

CC

Given a little time I will upgrade it to a qctp, I've got one on the 9" x 20" with about a dozen holders, but it's a nad's small for the Boxford, and in the short term that has to stay in place so .........

........... I'm looking for something to use ........... John, I don't have any facilities for surface grinding so I'll take it as comes if that's OK .......... thanks.

Stan / Dave ............ is The sort you mean

CC

The one on ebay is a piston type rather than a wedge type. The piston type is slightly cheaper and according to the BBS there seems to many satisfied users. I have a genuine Aloris wedge type on my lathe now but the one I put on the South Bend was a piston type and it worked fine. The experts say the tool holder alignment is less precise on the piston type but it was not a problem for me.

I made tool holders out of 6061 aluminum many years ago and they have stood up well. Besides, if I am sneaking up as close to the chuck as possible and touch a jaw there is no damage to the lathe and minimal damage to the tool holder. I do have a steel holder for a cut-off tool and for a boring bar, where there is a lot more stress on the holder.

Edit: The AXA size (used on 9" to 12" lathe) will take a 1/2" tool bit but you can't take advantage of that size with the horsepower you have. The nice part of this type of tool post is you can use any size tool bit without shims by adjusting the holder on the post. A 3/8" tool bit blank is cheaper than 1/2", quicker to grind to shape and plenty big for a 9" lathe.

I made tool holders out of 6061 aluminum many years ago and they have stood up well. Besides, if I am sneaking up as close to the chuck as possible and touch a jaw there is no damage to the lathe and minimal damage to the tool holder. I do have a steel holder for a cut-off tool and for a boring bar, where there is a lot more stress on the holder.

Edit: The AXA size (used on 9" to 12" lathe) will take a 1/2" tool bit but you can't take advantage of that size with the horsepower you have. The nice part of this type of tool post is you can use any size tool bit without shims by adjusting the holder on the post. A 3/8" tool bit blank is cheaper than 1/2", quicker to grind to shape and plenty big for a 9" lathe.

Divided He ad

Well-Known Member

- Joined

- Mar 21, 2008

- Messages

- 549

- Reaction score

- 2

Glad to see you got that there machine in the shop CC.

I've not been ignoring you .... just for some reason didn't see this post till now!!.... too many late nights me thinks! :-\

I'll be interested on your views on the performance of the beast. ;D

Ralph.

I've not been ignoring you .... just for some reason didn't see this post till now!!.... too many late nights me thinks! :-\

I'll be interested on your views on the performance of the beast. ;D

Ralph.

CC,

No problem I'll waft the bottom off on the grinder and throw it in the truck tomorrow so i will have it at Warwick, if I don't do that I'll forget it.

That holder you pointed out is the 100 series holder and is a tad small at 2-1/2" you will probably be better off with the 200 series

I might even have one of these sets somewhere brand new in a box, Stuff tends to breed during winter because of the dark nights.

I can remember buying one for a CNC conversion but finished up using a 6 station rotary changer, give me a couple of days to get the grey matter in place, it gets harder.

True story,

About two years ago this truck pulls up and the driver says I have a lathe for you.

"Where from?"

"From our depot"

"No I mean where has the lathe come from ? "

"Dunno, just told to deliver it here"

So went out and there is this old Myford ML7 on a big steel stand made out of a electrical junction box, I mean a BIG junction box. So lifted it off, nothing to sign, no paper work and truck leaves.

I think s??t I can't remember buying that, close look and it basically worn out but I don't restore machines so it can't be a job. Cut the stand up for scrap and throw the lathe in the Jabba so it must still be in there ?? ?????

Bought a Denford CNC off ebay the other month, the picture clearly shown it standing on a patch of floor about 10 foot square.

When I get it home some bastard had pinched the 10 foot square of floor 'cause I can't find it, now I'm struggling for somewhere to put it.

.

No problem I'll waft the bottom off on the grinder and throw it in the truck tomorrow so i will have it at Warwick, if I don't do that I'll forget it.

That holder you pointed out is the 100 series holder and is a tad small at 2-1/2" you will probably be better off with the 200 series

I might even have one of these sets somewhere brand new in a box, Stuff tends to breed during winter because of the dark nights.

I can remember buying one for a CNC conversion but finished up using a 6 station rotary changer, give me a couple of days to get the grey matter in place, it gets harder.

True story,

About two years ago this truck pulls up and the driver says I have a lathe for you.

"Where from?"

"From our depot"

"No I mean where has the lathe come from ? "

"Dunno, just told to deliver it here"

So went out and there is this old Myford ML7 on a big steel stand made out of a electrical junction box, I mean a BIG junction box. So lifted it off, nothing to sign, no paper work and truck leaves.

I think s??t I can't remember buying that, close look and it basically worn out but I don't restore machines so it can't be a job. Cut the stand up for scrap and throw the lathe in the Jabba so it must still be in there ?? ?????

Bought a Denford CNC off ebay the other month, the picture clearly shown it standing on a patch of floor about 10 foot square.

When I get it home some bastard had pinched the 10 foot square of floor 'cause I can't find it, now I'm struggling for somewhere to put it.

.

CC,

Regarding the tool post ...What Stan said! ( thanks Stan)

I have an AXA wedge type clone on my 2 HP Logan 12" x 39.

I have successfully taken some serious near full power cuts with this post and it took it well.

Personally, and I have no data to confirm this, I think the wedge type should be stiffer.

...The qualifier being, as you know, opinions are like back sides....everyone has one ;D

Dave

Regarding the tool post ...What Stan said! ( thanks Stan)

I have an AXA wedge type clone on my 2 HP Logan 12" x 39.

I have successfully taken some serious near full power cuts with this post and it took it well.

Personally, and I have no data to confirm this, I think the wedge type should be stiffer.

...The qualifier being, as you know, opinions are like back sides....everyone has one ;D

Dave

I may have made a serious error (one track mind) when the original post was about a 9" lathe and I automatically thought of a 9" North American size (British 4.5"). If in fact this is a British 9" (swings 18") then an Aloris AXA (100 series) is much too small. That size lathe is at the 400 series level. See the MSC page of Aloris tool posts and the recommended lathe size. (If you look at the prices, you will see why people buy import clones.

http://www1.mscdirect.com/CGI/GSDRVSM?PACACHE=000000069994951

http://www1.mscdirect.com/CGI/GSDRVSM?PACACHE=000000069994951

Stan said:If in fact this is a British 9" (swings 18")

Don't worry Stan it is 9" North American size, (British 4.5") 8)

CC

Stan said:I hope no one takes offense.

Only if you insist :big:

Anyway ................ on with the saga :

Inverter arrived yesterday so this afternoon I've been "wiring things up" .............. after a little :wall: coupled with a few well chosen words things began to fall into place and we now have "rotation" .................

**************** The Beast Lives ****************

anyway, it runs quietly and smoothly at lower speeds, at higher speeds it's "surging" ..... by hand everything turns over quite easily so I don't know if it's a motor problem (it did get very hot at high speed) or if it's my pathetic efforts at programming the inverter ??? ....... a degree in computer science would help ............. anyone wanting to download the manual so you can have a laugh at what I'm trying to do :big: ............... Click here ............ for now I'm just letting it spin at low speed ................ It's all had a good oiling and to be fair I don't think it's run for many a year

Next step ............... some sort of toolpost so I can at least try turning, if only using a toothpick ;D

CC

John Stevenson said:CC, Did you swap the motor wiring over from star to delta to run on 240 volts ?

OK where's the "WHOOSH" ............ / Over My Head ................ Smiley

errrrrrrrrr ................. John .................. I've read the instruction book so many times I cam probaly recite it backwards in French ??? ...............but ................... it appears I've missed something :fan:

OK ...... now I've stopped slapping mi'self with a wet Halibut  ............

............

... John,

Red ........... "A" ............... T1

Yellow......... "B" ................ T2

Blue ........... "C" ................ T3

Everything spun up, but in the wrong direction so I then reversed Red and Yellow ........... and it spins the right way, but Torque is "conspicuous by it's absence" ???

Does this help or do I need to take the motor out again and look at the wiring to the terminals ................ btw ........... I've turned it off

CC

... John,

Red ........... "A" ............... T1

Yellow......... "B" ................ T2

Blue ........... "C" ................ T3

Everything spun up, but in the wrong direction so I then reversed Red and Yellow ........... and it spins the right way, but Torque is "conspicuous by it's absence" ???

Does this help or do I need to take the motor out again and look at the wiring to the terminals ................ btw ........... I've turned it off

CC

That's why it's getting hot.

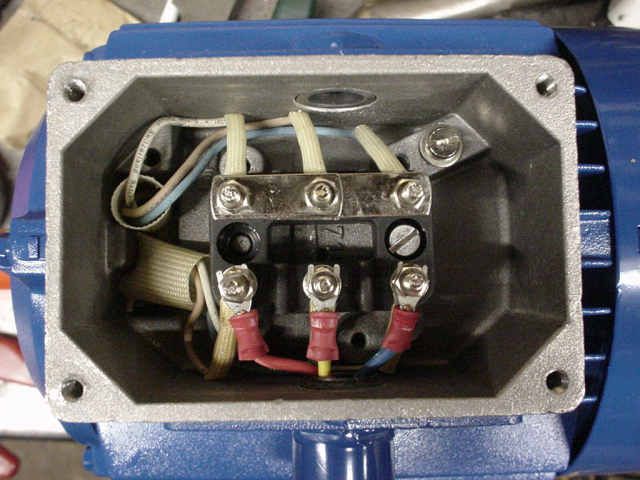

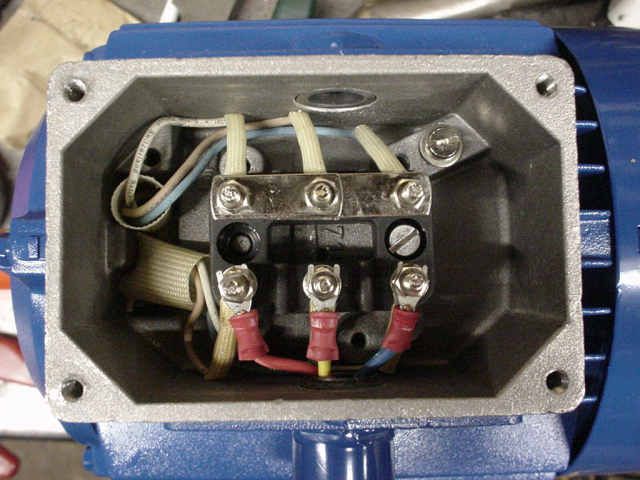

Heres what the inside of a 440 volt motor looks like.

You have all three connector strips linking the star point and each 440 v wire goes on to each one.

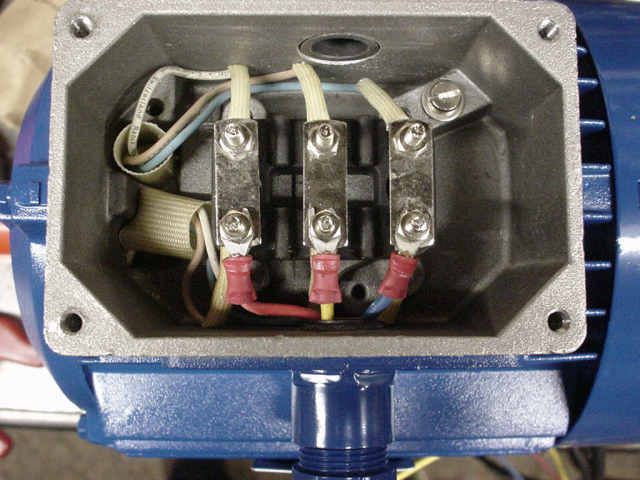

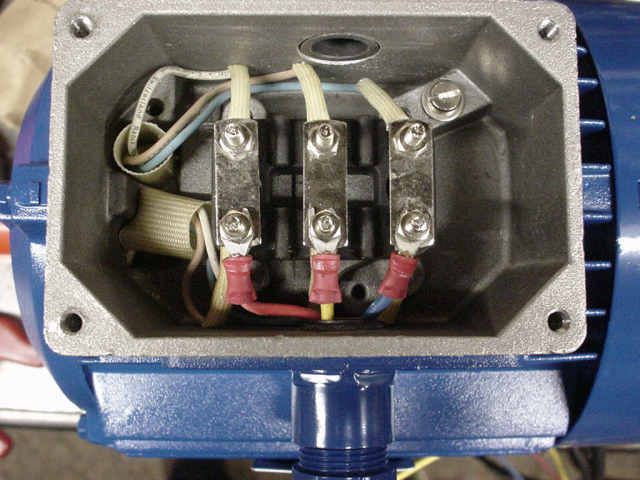

Now here is how the links have to be connected to go onto 240 volt 3 phase.

I'll read thru the manual and list the best settings for this application.

Just spotted your last post whist poking the keys.

torque is absent as you are only supplying 1/3 of the current.

Swap the motor links over and then try it but I'll see if we can't get some better settings or at least safer ones.

Off to read the manual.

We used to make ink mixing machines at one stage, like a food mixer on steroids, Just a big 3 phase motor on 240 v with VFD to get variable speed, driving a paddle.

over the years we must have sold close to 200 of these with all different kinds of invertor depending on who was offering the best deal, so I know my way round these.

Heres what the inside of a 440 volt motor looks like.

You have all three connector strips linking the star point and each 440 v wire goes on to each one.

Now here is how the links have to be connected to go onto 240 volt 3 phase.

I'll read thru the manual and list the best settings for this application.

Just spotted your last post whist poking the keys.

torque is absent as you are only supplying 1/3 of the current.

Swap the motor links over and then try it but I'll see if we can't get some better settings or at least safer ones.

Off to read the manual.

We used to make ink mixing machines at one stage, like a food mixer on steroids, Just a big 3 phase motor on 240 v with VFD to get variable speed, driving a paddle.

over the years we must have sold close to 200 of these with all different kinds of invertor depending on who was offering the best deal, so I know my way round these.

John,

I've just spent a couple of minutes comparing the wiring configurations, which don't change do they  ??? ........... then I eventually spotted the links  :wall:  .............. just colour me "stupid"

Thanks

CC

I've just spent a couple of minutes comparing the wiring configurations, which don't change do they  ??? ........... then I eventually spotted the links  :wall:  .............. just colour me "stupid"

Thanks

CC

Similar threads

- Replies

- 37

- Views

- 11K