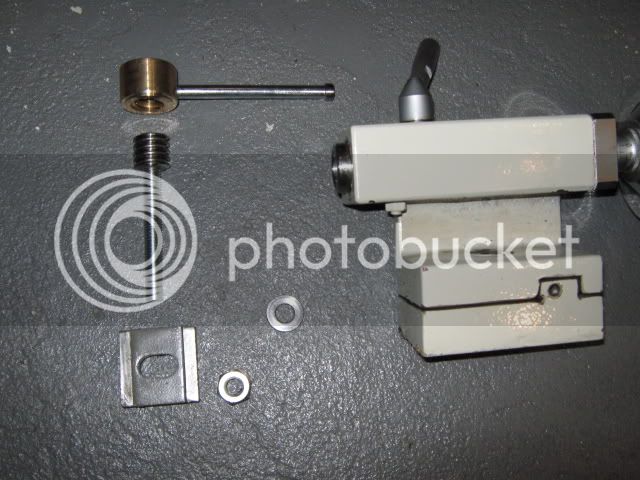

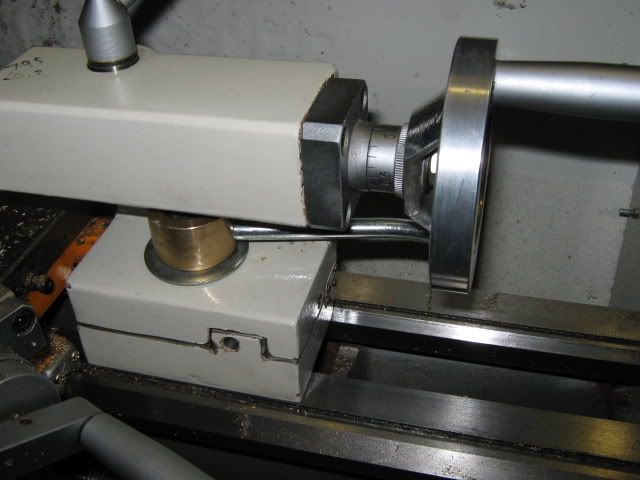

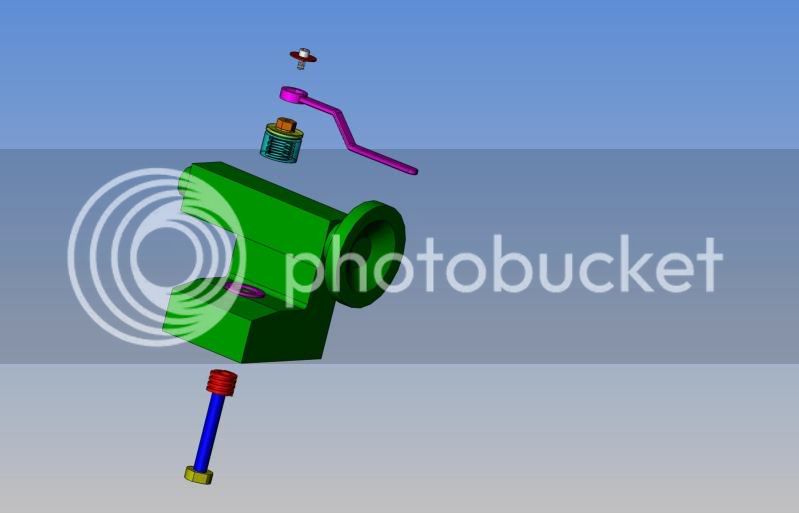

In addition to hanging out and posting on this forum, I also frequent the "Home shop Machinist" website. Earlier this week, a clever gentleman posted some pictures of a system which he devised to quickly lock the tailstock in place on his lathe without having to modify the lathe in any way, and without using a wrench. It struck me as being a very clever solution, and got me digging though my scrap bin. I have a peice of 1" Acme threaded rod and follower nut that I have been saving for years to use on "SOMETHING", and this may be it!!!