You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

taig tips/setup Speedy's ultimate help wanted thread.

- Thread starter Speedy

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Hey Speedy

An angle iron bench with plywood or chipboard on top to dampen the noise maybe? Suspect that a metal top might be a little noisy...

I put mine on a chipboard stair tread from the local wood yard, 1.25" thick, with some large rubber feet under it, it sits on top of my shop-built router table as my machine shop is my wood shop is my painting room is my etc etc etc (space is at a premium )

)

Easily moved around, but stays put while using it.

As to your pulleys, try giving them a whap with a soft-faced hammer just to break the "seal" if that doesn't work, get a hub puller! (Cdn Tire has one they sell for removing faucet handles that would be just the right size)

Cheers, Joe

An angle iron bench with plywood or chipboard on top to dampen the noise maybe? Suspect that a metal top might be a little noisy...

I put mine on a chipboard stair tread from the local wood yard, 1.25" thick, with some large rubber feet under it, it sits on top of my shop-built router table as my machine shop is my wood shop is my painting room is my etc etc etc (space is at a premium

Easily moved around, but stays put while using it.

As to your pulleys, try giving them a whap with a soft-faced hammer just to break the "seal" if that doesn't work, get a hub puller! (Cdn Tire has one they sell for removing faucet handles that would be just the right size)

Cheers, Joe

modified the title of this thread :big:

I went to my local tool store

they carry lots of chinese stuff and "king canada" brand

I went to purchase some lathe cutters called "toolmex", altho I did not buy them because they were just a tad bit shorter and fatter then the blank I have in my holder now. I know that the tool needs to be centered with the work (not to high, not to low) but this tool fit into the holder just fine, will this work for my taig?

also, they have blanks that are close to the same size (I plan on learning how to grind myself)

I went to my local tool store

they carry lots of chinese stuff and "king canada" brand

I went to purchase some lathe cutters called "toolmex", altho I did not buy them because they were just a tad bit shorter and fatter then the blank I have in my holder now. I know that the tool needs to be centered with the work (not to high, not to low) but this tool fit into the holder just fine, will this work for my taig?

also, they have blanks that are close to the same size (I plan on learning how to grind myself)

Taig's steel bed is, I'm led to understand, precision ground before it is bonded to the al extrusion with concrete. Therefore "lapping" here is really just a final polish of the aluminium. If something as agressive as valve lapping compound were to be used the grains would embed in the al and the only metal removed would be from the bed. This is NOT what is wanted. I'm told that even toothpaste is too aggressive for this operation and therefore your kitchen scourer powder is near ideal, removing nothing from the bed but polishing the al to it. I hope that makes sense.

When you have managed to remove the pulley, examine the shaft. A dog tooth grub screw usually bites into it. If you ever want to remove it again, a tiny brass plug in the bottom of the hole under the screw will be ok (having corrected the damage)

Ray

When you have managed to remove the pulley, examine the shaft. A dog tooth grub screw usually bites into it. If you ever want to remove it again, a tiny brass plug in the bottom of the hole under the screw will be ok (having corrected the damage)

Ray

Speedy said:I went to purchase some lathe cutters called "toolmex", altho I did not buy them because they were just a tad bit shorter and fatter then the blank I have in my holder now. I know that the tool needs to be centered with the work (not to high, not to low) but this tool fit into the holder just fine, will this work for my taig?

Speedy

The issue here is that the cutting edge of the tool needs to be at the centreline of the work.. I have had to shim up a tool with various things (Paper, brass shim stock etc) to achieve this, especially as I have tried to grind some of my own bits and the dimensions are sometimes a little erratic :big:

The good thing is that the taig tool post is just a piece of 1 x 1 aluminum with a hole to suit the 10-32 cap screw that holds it on the carriage and a slot in it for the tool. Therefore, if you have some tool blanks of a different dimension, it sure isn't too difficult to whip up a dedicated tool post for them. There are QCTPs out there for Taigs as well.

As to the location of the motor in my set-up, for sure it was to avoid filling the motor casing with swarf and anything else.

A while back somebody on this board posted a photo of his Taig setup that had the lathe on top of a shop-made wooden box that contained both the motor and drawers for accessories. If I had to do it again I would seriously consider some version like that.

Joe

Tin Falcon

Well-Known Member

- Joined

- Jul 9, 2007

- Messages

- 7,207

- Reaction score

- 787

Speedy:

As far as tool size and height. I have used everything from 1/8 to 3/8 cutting tools in both my 7x 10 mini lathe and my 9" South Bend. The 1/8 bits used for grooving and backed up in a piece of 3/8 mild steel with a 1/8 groove in it. If I had to pick one size and stay with it for my machines i would probably do 1/4 inch the South Bend is a tool room lathe and the mini is well mini so neither is designed for production hogging cuts.

Tool height is especially important for certain operations.

Facing if tool is not center height face will not clean up you will have a pip left.

Parting too low you will have a stub left over .to high you will have a stub that may catch the tool and break it or tear the work out of the chuck .

Tapers if the tool is not center it can change the taper angle. I use a 6" rule to set center height. Hold the rule lightly between the tool and the round stock rule will be vertical when tool is on center. the easiest way to adjust center height of tool is a quick change tool post. these save lots of time and headache setting tools or you can tape shim sets to cutters to save time.

the A2Z CNC QCTP works well on my mini lathe.

Stoning your hss bits drastically improves performance and finish. A regular wheel will hollow grind so you only need to stone the edges. And to start just grind up a couple of general purpose bits. yes there is an ideal geometry for every material but for the hobbyist just starting out you do not need the perfect bit for every job or metal.

I posted the specs for a gp bit around here a while ago. if you need me to I can dig it up or repost.

Tin

As far as tool size and height. I have used everything from 1/8 to 3/8 cutting tools in both my 7x 10 mini lathe and my 9" South Bend. The 1/8 bits used for grooving and backed up in a piece of 3/8 mild steel with a 1/8 groove in it. If I had to pick one size and stay with it for my machines i would probably do 1/4 inch the South Bend is a tool room lathe and the mini is well mini so neither is designed for production hogging cuts.

Tool height is especially important for certain operations.

Facing if tool is not center height face will not clean up you will have a pip left.

Parting too low you will have a stub left over .to high you will have a stub that may catch the tool and break it or tear the work out of the chuck .

Tapers if the tool is not center it can change the taper angle. I use a 6" rule to set center height. Hold the rule lightly between the tool and the round stock rule will be vertical when tool is on center. the easiest way to adjust center height of tool is a quick change tool post. these save lots of time and headache setting tools or you can tape shim sets to cutters to save time.

the A2Z CNC QCTP works well on my mini lathe.

Stoning your hss bits drastically improves performance and finish. A regular wheel will hollow grind so you only need to stone the edges. And to start just grind up a couple of general purpose bits. yes there is an ideal geometry for every material but for the hobbyist just starting out you do not need the perfect bit for every job or metal.

I posted the specs for a gp bit around here a while ago. if you need me to I can dig it up or repost.

Tin

Raggle

thanks for the info, I feel more confident about lapping now

im not to sure what you mean about the brass plug.

Joe d

lol I cant make my own holders yet, no mill (thats my next BIG want!)

(thats my next BIG want!)

I will think about the placement of the motor, but if I put it below the table top then belt changing might be a hassle?

Tin Falcon

so staying with 1/4 would be best, price wise also.

an already ground bit or carbid tipped is about 4-6 dollars (1/4) and a 1/4 blank is 2 dollars

http://busybeetools.ca/cgi-bin/picture10?NTITEM=160110

should I buy this for reference and getting measurements (and to start off)

http://busybeetools.ca/cgi-bin/picture10?NTITEM=B287C6

what is "GP"? I will see if I can also locate your thread.

now im getting intimidated about grinding, when you say stoning you mean sharpening by hand?

any links to good grinding sites?

can anyone provide links to what I will need to get started on grinding? (my dad has a bench grinder)

what jig? wheels? etc (maybe even compatible for mill bits when I get a mill)

also a link to a good qctp

not to mention I am going to need a shopping list to get me started! with my lathe

:big:

thanks for the info, I feel more confident about lapping now

im not to sure what you mean about the brass plug.

Joe d

lol I cant make my own holders yet, no mill

I will think about the placement of the motor, but if I put it below the table top then belt changing might be a hassle?

Tin Falcon

so staying with 1/4 would be best, price wise also.

an already ground bit or carbid tipped is about 4-6 dollars (1/4) and a 1/4 blank is 2 dollars

http://busybeetools.ca/cgi-bin/picture10?NTITEM=160110

should I buy this for reference and getting measurements (and to start off)

http://busybeetools.ca/cgi-bin/picture10?NTITEM=B287C6

what is "GP"? I will see if I can also locate your thread.

now im getting intimidated about grinding, when you say stoning you mean sharpening by hand?

any links to good grinding sites?

can anyone provide links to what I will need to get started on grinding? (my dad has a bench grinder)

what jig? wheels? etc (maybe even compatible for mill bits when I get a mill)

also a link to a good qctp

not to mention I am going to need a shopping list to get me started! with my lathe

:big:

Regarding removing the headstock pulley, this note came from the factory with my Taig lathe.

"IMPORTANT NOTICE

Headstock pulleys are furnished with close fitting tolerances.

Heating pulley in hot water or use of propane torch will expand pulley to

slide on spindle freely.

DO NOT USE HAMMER"

To me the torch is a little scary. You might try heating the pulley with a hair dryer or a heat gun.

A little heat might help the motor pulley as well. I can't speak for the motor as I didn't buy the Taig motor. I'm running a Sherline DC motor on my Taig lathe.

Take a look at to see a really fine looking Taig lathe, take a look at John Bentley's machine.

http://lathes.jrbentley.com/taig.html

Regards,

Chuck

"IMPORTANT NOTICE

Headstock pulleys are furnished with close fitting tolerances.

Heating pulley in hot water or use of propane torch will expand pulley to

slide on spindle freely.

DO NOT USE HAMMER"

To me the torch is a little scary. You might try heating the pulley with a hair dryer or a heat gun.

A little heat might help the motor pulley as well. I can't speak for the motor as I didn't buy the Taig motor. I'm running a Sherline DC motor on my Taig lathe.

Take a look at to see a really fine looking Taig lathe, take a look at John Bentley's machine.

http://lathes.jrbentley.com/taig.html

Regards,

Chuck

Michael;

I'm not much ahead of you on the learning curve but for what it's worth....

Don't be intimidated by grinding 1/4" toolbits. When I bought my used Taig it came with a set of Taig's pre-ground bits which I set aside and use as a reference when grinding my own. With the 1/4' size its only the parting off tool and the boring bit that require a considerable amount of time to remove metal (25 minutes for me). The other tool shapes ground up quickly and if you don't rush yourself (hand holding the bit forced me to take my time, cooling the bit in water when it got warm to hold) it's relatively easy to sneak up on the angles required. I just purchased a small metal machinist's protractor to grind specific angles - worked fine - as far as I was concerned. PS - take a look at your Dad's grinder and see how rough (uneven) the face of the wheels are before trying to grind toolbits. At least reface the wheels or better yet get new ones specifically for doing toolbits.

The Sherline website has an article on grinding your own toolbits that was useful to me. I've stuck with 1/4" for now and have bought blanks from BusyBee when they went on sale.

KBC is also great to deal with for tooling, and also gives you access to USA made tooling as well as China made. They will regularly sent out sale flyers in the way BusyBee does if you request the catalog.

http://www.kbctools.com/can/

Lee Valley has a Taig instruction booklet in PDF form (free) on their website. Go to the last item on this page "Taig Lathe Instruction Booklet" and click "Instr". This contains dimensional data for mounting the motor off to the left of the headstock instead of behind it.

http://www.leevalley.com/wood/page.aspx?c=1&p=43104&cat=1,330,50260&ap=1

Lots of data on the web for tool shapes - I've tried some odd stuff recommended by others that work well for specific metals. Just grind away and go at it!!

Cheers

Garry

I'm not much ahead of you on the learning curve but for what it's worth....

Don't be intimidated by grinding 1/4" toolbits. When I bought my used Taig it came with a set of Taig's pre-ground bits which I set aside and use as a reference when grinding my own. With the 1/4' size its only the parting off tool and the boring bit that require a considerable amount of time to remove metal (25 minutes for me). The other tool shapes ground up quickly and if you don't rush yourself (hand holding the bit forced me to take my time, cooling the bit in water when it got warm to hold) it's relatively easy to sneak up on the angles required. I just purchased a small metal machinist's protractor to grind specific angles - worked fine - as far as I was concerned. PS - take a look at your Dad's grinder and see how rough (uneven) the face of the wheels are before trying to grind toolbits. At least reface the wheels or better yet get new ones specifically for doing toolbits.

The Sherline website has an article on grinding your own toolbits that was useful to me. I've stuck with 1/4" for now and have bought blanks from BusyBee when they went on sale.

KBC is also great to deal with for tooling, and also gives you access to USA made tooling as well as China made. They will regularly sent out sale flyers in the way BusyBee does if you request the catalog.

http://www.kbctools.com/can/

Lee Valley has a Taig instruction booklet in PDF form (free) on their website. Go to the last item on this page "Taig Lathe Instruction Booklet" and click "Instr". This contains dimensional data for mounting the motor off to the left of the headstock instead of behind it.

http://www.leevalley.com/wood/page.aspx?c=1&p=43104&cat=1,330,50260&ap=1

Lots of data on the web for tool shapes - I've tried some odd stuff recommended by others that work well for specific metals. Just grind away and go at it!!

Cheers

Garry

Tin Falcon

Well-Known Member

- Joined

- Jul 9, 2007

- Messages

- 7,207

- Reaction score

- 787

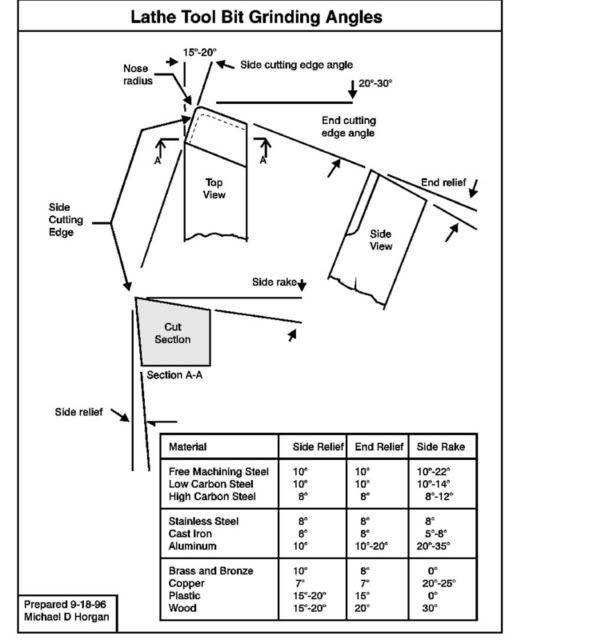

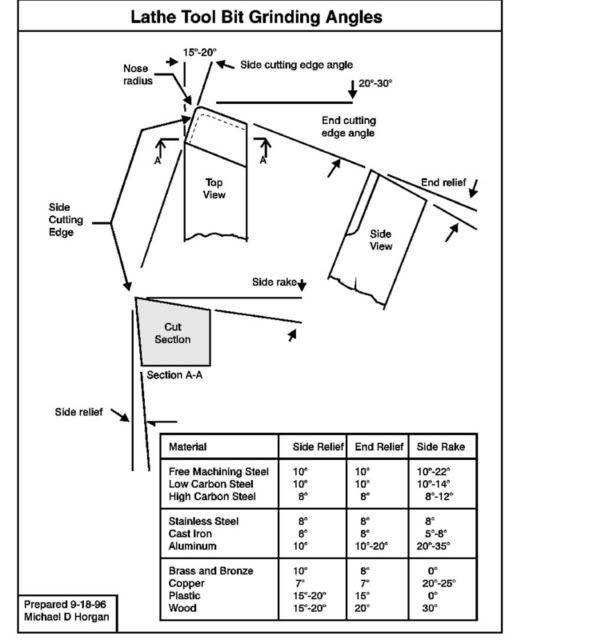

OK Micheal lets try this again. I inteded to post this am but never quite put the post on the board. You know that four letter word? W-O-R-K. Anyway to answer you questions

Lots of discussion here http://www.homemodelenginemachinist.com/index.php?topic=1494.0

Here are a couple of excerpts(edited a little to make sense here)

The idea of a general purpose bit suitable for most materials has been mentioned.

The recommended geometry for a GP bit is as follows.

End cutting edge angle 30 degrees

Side cutting edge angle Zero degrees

Side relief 10 degrees.

End relief 10 degrees.

Side rake 15 degrees

back rake 5 degrees.

Nose radius 1/16th inch

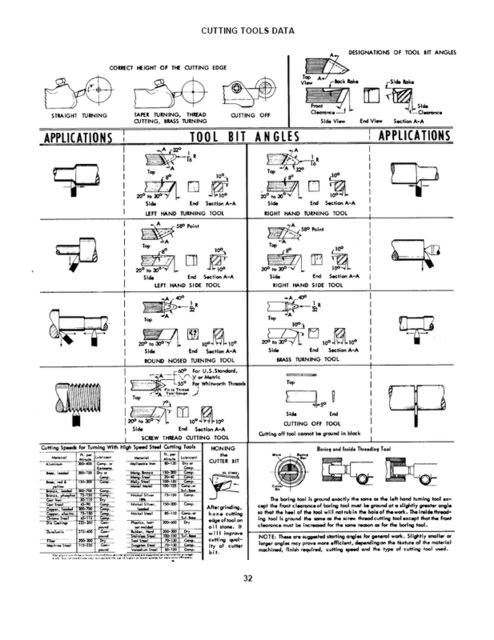

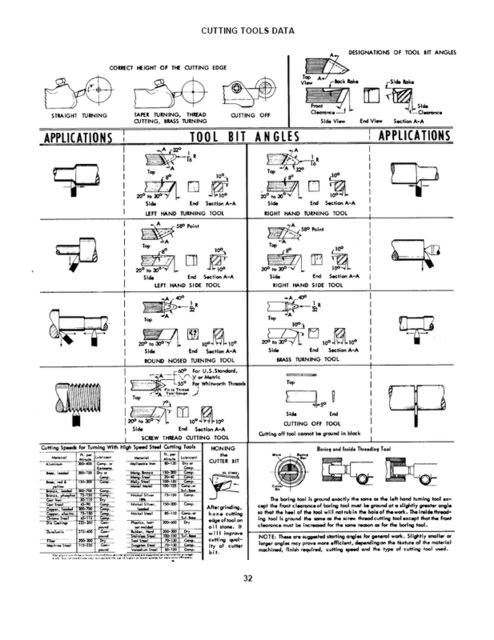

For definitions of these terms see the charts posted below

well what does this look like?? since bits are generally small a while back I did a wooden demo to illustrate the concept.

Here is a photo of a right hand bit.

and here is the top view

A left hand version of this would likely work well as a fly cutter.

Hope this helps

Tin

I went to machinist school about 11 years ago at the beginning of the lathe block of instruction we were taught the basics of the lathe and tool grinding when we got to the lab we were each given a piece of IIRC 1/4 mild steel and told to grind it like a cutter (general purpose). The cutters we actually used were more or less sharp and ready to go but we had to grind our own as needed. no insert stuff in school. I have been able to grind a usable cutter for whatever need since. Not necessarily the prettiest. As time has gone on they have fewer facets and look more like the text books and photos.

Experience has taught that stoning makes a huge difference in the way a HSS lathe bit cuts.

Entire books have been written about cutting tool material and geometry.

Here are a couple of charts that may help

I prefer 0 degree side cutting angle myself but the larger angles ar better for roughing.

The way a tool is ground also depends on the tool holder for instance a lantern tool post had built in back rake a QC does not.

I ground the form tool to do the little candle holder posted in the galley.

Back rake is not needed for brass and zero back rake will work for other materials as well.

Hope this helps.

And do not limit yourself to facing and cutting tools

you can grind /make your own boring bars

The round one is made from drill rod the the other from a lathe tool blank.

And last but not least form tools like this one.

The tool is on the right the miniature candle stick and a dime for size reference.

For QCTP here is one place to look

www.littlemachineshop.com

Or you can go directly to A2Z CNC

they look like this

Hope this all helps

Tin

Tin

Lots of discussion here http://www.homemodelenginemachinist.com/index.php?topic=1494.0

Here are a couple of excerpts(edited a little to make sense here)

The idea of a general purpose bit suitable for most materials has been mentioned.

The recommended geometry for a GP bit is as follows.

End cutting edge angle 30 degrees

Side cutting edge angle Zero degrees

Side relief 10 degrees.

End relief 10 degrees.

Side rake 15 degrees

back rake 5 degrees.

Nose radius 1/16th inch

For definitions of these terms see the charts posted below

well what does this look like?? since bits are generally small a while back I did a wooden demo to illustrate the concept.

Here is a photo of a right hand bit.

and here is the top view

A left hand version of this would likely work well as a fly cutter.

Hope this helps

Tin

I went to machinist school about 11 years ago at the beginning of the lathe block of instruction we were taught the basics of the lathe and tool grinding when we got to the lab we were each given a piece of IIRC 1/4 mild steel and told to grind it like a cutter (general purpose). The cutters we actually used were more or less sharp and ready to go but we had to grind our own as needed. no insert stuff in school. I have been able to grind a usable cutter for whatever need since. Not necessarily the prettiest. As time has gone on they have fewer facets and look more like the text books and photos.

Experience has taught that stoning makes a huge difference in the way a HSS lathe bit cuts.

Entire books have been written about cutting tool material and geometry.

Here are a couple of charts that may help

I prefer 0 degree side cutting angle myself but the larger angles ar better for roughing.

The way a tool is ground also depends on the tool holder for instance a lantern tool post had built in back rake a QC does not.

I ground the form tool to do the little candle holder posted in the galley.

Back rake is not needed for brass and zero back rake will work for other materials as well.

Hope this helps.

And do not limit yourself to facing and cutting tools

you can grind /make your own boring bars

The round one is made from drill rod the the other from a lathe tool blank.

And last but not least form tools like this one.

The tool is on the right the miniature candle stick and a dime for size reference.

For QCTP here is one place to look

www.littlemachineshop.com

Or you can go directly to A2Z CNC

they look like this

Hope this all helps

Tin

Tin

wow Tin.

thank you! also an interesting read as it brings in other cutters.

I was going to ask if a tool jig would help but it seems that holding the tool would be the ideal way?

(one blank can do 2 tools right? one cutter on the each side)

I did read that someone when they started were given purchased bits to duplicate and also to see how the purchased ones cut. I am thinking that might be a good idea. (with lee valleys)

any specific grinding discs that I should look into (also bran name for quality?)

arkansa stone for sharpening?

anyone used carbide with a Taig?

or is carbide something that is more towards cnc equipment.

I will look into the QCTP but I am going to wait with that or I will be on the verge of........ broke! :big:

ps, Tin the second picture is hard to make out. would it be bigger if emailed?

thank you! also an interesting read as it brings in other cutters.

I was going to ask if a tool jig would help but it seems that holding the tool would be the ideal way?

(one blank can do 2 tools right? one cutter on the each side)

I did read that someone when they started were given purchased bits to duplicate and also to see how the purchased ones cut. I am thinking that might be a good idea. (with lee valleys)

any specific grinding discs that I should look into (also bran name for quality?)

arkansa stone for sharpening?

anyone used carbide with a Taig?

or is carbide something that is more towards cnc equipment.

I will look into the QCTP but I am going to wait with that or I will be on the verge of........ broke! :big:

ps, Tin the second picture is hard to make out. would it be bigger if emailed?

Tin Falcon

Well-Known Member

- Joined

- Jul 9, 2007

- Messages

- 7,207

- Reaction score

- 787

My grinding wheel is just the cheapy that came on the Jet Grinderany specific grinding discs that I should look into (also bran name for quality?)

Arkansas stone for sharpening?

My shop stone was $2.00 at a yard sale . But if I was having to buy new I would likey look for a USA brand such as 3m or norton

My bench stone is an Arkansas oil stone you are just smoothing out the edge not remcahanging the shap much also itis a good idea to do the tip radius by hand.

A topic of lenthy discussion carbide vs HSSanyone used carbide with a Taig?

or is carbide something that is more towards cnc equipment.

Carbide can be used in the hobby shop. there are advantages and disadvantages.

Carbide likes speed and imho is not best suited to small hobby machines .

advantages

it will cut faster than HSS

longer tool life if used properly

Disadvatages

will chip with interrupted cuts on steel

can chip with intermittent coolant

need Green wheel or diamond wheel to sharpen.

In you shoes I would probably buy a couple an try them out.

ps, Tin the second picture is hard to make out. would it be bigger if emailed?

I will try to get you a more readable copy

If short on cash by all means wait a bit on the QCTP but try to be frugal with other little purchases that add up so you can save for a qctp. I have seen new ones on e-bay for sale, shop around for deals.

Tin

I will check out the wheels on my dads grinder.

I know he has some stones also so im sure im set for grinding

carbide dosnt sound like its for me, small machine and im sure in my newby state I will fudge allot of things up in a hurry! lol.

I am talking with a x tool maker about tools and measuring equipment etc, he may be able to help me out as he is selling off. (if its good I will jump on it)

but that aside, my original plan is just to purchase blanks and maybe taigs already ground tools just to start and give me reference, other then that and stock to machine I would be saving money

I know he has some stones also so im sure im set for grinding

carbide dosnt sound like its for me, small machine and im sure in my newby state I will fudge allot of things up in a hurry! lol.

I am talking with a x tool maker about tools and measuring equipment etc, he may be able to help me out as he is selling off. (if its good I will jump on it)

but that aside, my original plan is just to purchase blanks and maybe taigs already ground tools just to start and give me reference, other then that and stock to machine I would be saving money

Tin Falcon

Well-Known Member

- Joined

- Jul 9, 2007

- Messages

- 7,207

- Reaction score

- 787

Micheal check you e-mail box

Tin

Tin

Speedy said:(one blank can do 2 tools right? one cutter on the each side)

I

or is carbide something that is more towards cnc equipment.

I will look into the QCTP but I am going to wait with that or I will be on the verge of........ broke! :big:

HSS blank bits are cheap so really no need to form each end. QCTP not so cheap, I have one and find myself migrating back to the original rocker tool post. When turning smaller/shorter pieces say <2 inches there just isnt enough room for that toolpost. The rocker post keeps the tool bit closer to the cross slide center line and I am finding for taking light cuts <2-3 thou it works better.

Get a dozen blank bits and have fun with the grinder, just watch them fingers, those bits get hot real fast

Robert

hey guys.

I was going to lap yesterday but it turns out I dont have Taigs recommended SAE 20 motor oil,

trying to save myself from purchasing that oil. can I get away with using 5w-30 synthetic? (tho I dont want to cheap out and hurt something)

the instructions read

"use generous amount of lapping paste. if stroking feels excessively abrasive add more oil, approximate ratio one teaspoon abrasive to 1/4 cup light oil (SAE 20 motor oil)."

I was going to lap yesterday but it turns out I dont have Taigs recommended SAE 20 motor oil,

trying to save myself from purchasing that oil. can I get away with using 5w-30 synthetic? (tho I dont want to cheap out and hurt something)

the instructions read

"use generous amount of lapping paste. if stroking feels excessively abrasive add more oil, approximate ratio one teaspoon abrasive to 1/4 cup light oil (SAE 20 motor oil)."

K

Kermit

Guest

Speedy said:hey guys.

I was going to lap yesterday but it turns out I dont have Taigs recommended SAE 20 motor oil,

Their is NO reason why 30W oil would not work in its place. Get the cheapest bottle of no name brand Straight 30 weight you find. These are often just oil without detergents or other gasoline engine cleaning additives. That's EXACTLY what you want. Cheap straight non detergent oil. Around here it used to be found at the local Wallyworld as Golden state 30W motor oil. No additives in that stuff.

Just thought you'd like to know. Who sells small bottles of 20W anyway? (I'm putting $100 on the answer being Taig)

Kermit

Similar threads

- Replies

- 86

- Views

- 21K