You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

taig tips/setup Speedy's ultimate help wanted thread.

- Thread starter Speedy

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

okay so its done!

went well, taig manual says 30-40 strokes and you should be done, I know I didnt do 30 (less) but I was happy with the results and how smooth everything went, I am thinking it maybe could use a tad more but im going to hold off.... it can always be done later (I know I will be very pleased with this)

I am cleaning everything now, HOW DO YOU TAKE OFF THE TOP CROSS SLIDE CARRIAGE? (had to make that in caps :big

is it just the brass nut in the center of the had wheel?

thanks for all the help you guys are providing ;D

went well, taig manual says 30-40 strokes and you should be done, I know I didnt do 30 (less) but I was happy with the results and how smooth everything went, I am thinking it maybe could use a tad more but im going to hold off.... it can always be done later (I know I will be very pleased with this)

I am cleaning everything now, HOW DO YOU TAKE OFF THE TOP CROSS SLIDE CARRIAGE? (had to make that in caps :big

is it just the brass nut in the center of the had wheel?

thanks for all the help you guys are providing ;D

okay now that my taig is all nice and clean its time to move onto a shopping list.

I am hoping you can all pitch in and let me know what is essential.

I am still going the HSS route, but I thought maybe this would be a good buy also

http://busybeetools.ca/cgi-bin/picture10?NTITEM=B2122

(these are toss away tips? or can they still be sharpened with a different wheel)

and I have a digital caliper.

please add everything you think I should have.

and if you have anything laying around I might be interested

spend my money good :big:

I am hoping you can all pitch in and let me know what is essential.

I am still going the HSS route, but I thought maybe this would be a good buy also

http://busybeetools.ca/cgi-bin/picture10?NTITEM=B2122

(these are toss away tips? or can they still be sharpened with a different wheel)

and I have a digital caliper.

please add everything you think I should have.

and if you have anything laying around I might be interested

spend my money good :big:

sorry for chain posts :big:

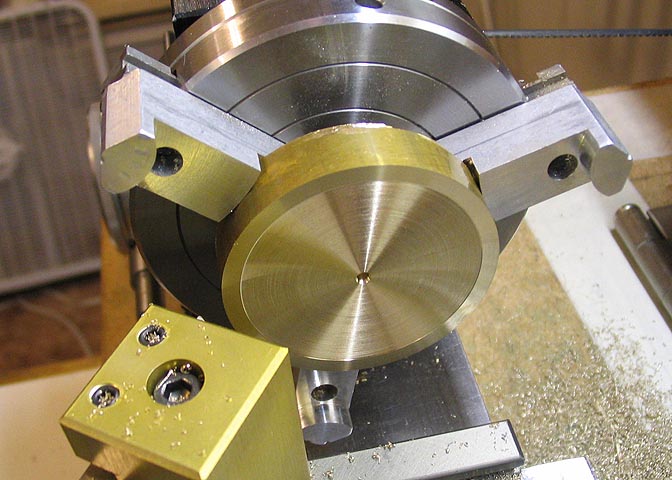

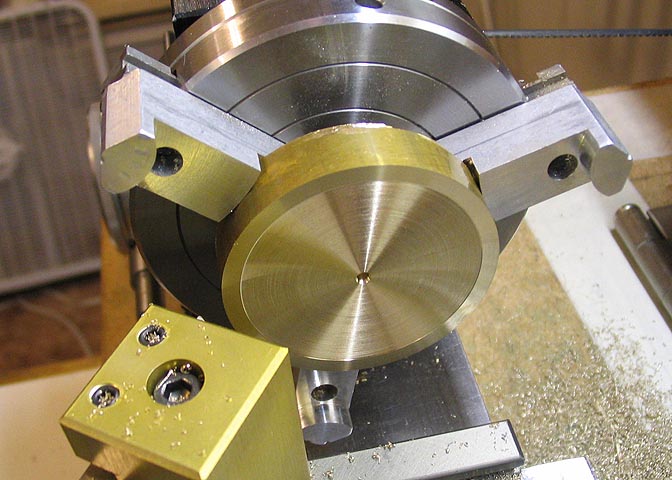

I was wondering for bigger parts you can get a raiser blocks. but my self centering 3 jaw chuck maxes out on my lathe already.

if I got the raiser blocks, how do I get my chuck to open more?? ??? :-\

I was wondering for bigger parts you can get a raiser blocks. but my self centering 3 jaw chuck maxes out on my lathe already.

if I got the raiser blocks, how do I get my chuck to open more?? ??? :-\

Hi Speedy

Is this the Taig 3-jaw? If so, the aluminum jaws are held on with 2 cap screws each... one could just remove them and replace with some aluminum bits a little longer than needed for the job in hand. Face them, and cut a recess in the jaws slightly less than the diameter of the work-piece, and you have a custom work holder that is going to be concentric to the axis of rotation.

Hope this helps!

Joe

Is this the Taig 3-jaw? If so, the aluminum jaws are held on with 2 cap screws each... one could just remove them and replace with some aluminum bits a little longer than needed for the job in hand. Face them, and cut a recess in the jaws slightly less than the diameter of the work-piece, and you have a custom work holder that is going to be concentric to the axis of rotation.

Hope this helps!

Joe

Speedy, close your three jaw down all the way and cut steps in the outside of the jaws. Then reverse the jaws and you can hold bigger bits. Just watch that you don't cut into the tops of the SHCS's that hold the jaws to the chuck.

Be careful turning large stock with the aluminum jaws. Don't take cuts that are too deep or you risk pulling the work out of the chuck.

Check it out;

Dean W

Be careful turning large stock with the aluminum jaws. Don't take cuts that are too deep or you risk pulling the work out of the chuck.

Check it out;

Dean W

thanks for the help guys!

I didn't think of doing that, I wont try it for awhile. dont want to mess anything up just yet... even tho I do have an extra set of jaws.

will HSS work alright for cold rolled steel? I dont want to dull my bits fast but I have lots of crs in the house.

I didn't think of doing that, I wont try it for awhile. dont want to mess anything up just yet... even tho I do have an extra set of jaws.

will HSS work alright for cold rolled steel? I dont want to dull my bits fast but I have lots of crs in the house.

Tin Falcon

Well-Known Member

- Joined

- Jul 9, 2007

- Messages

- 7,207

- Reaction score

- 787

Speedy with proper speeds feeds and a bit of sulpherised oil you should be fine.

1018 is the most common cold rolled and has a machinability index of 78%

1212 = 100%

12L14 = 170%

cold drawn aluminum = 360%

BTW sulpherised oil should be available from the local plumbing supply hardware store home improvement center. Problay just called cutting oil. Use this for STEEL.

Tin

1018 is the most common cold rolled and has a machinability index of 78%

1212 = 100%

12L14 = 170%

cold drawn aluminum = 360%

BTW sulpherised oil should be available from the local plumbing supply hardware store home improvement center. Problay just called cutting oil. Use this for STEEL.

Tin

thanks Tin.

well I just reolized I have no idea what my crs is (I will assume its 1018) :big:

is carbide geared more towards steel? (longer tool life)

also, if my tools get dull how do I sharpen them? oil stone? (taig tools, preground HSS)

well I just reolized I have no idea what my crs is (I will assume its 1018) :big:

is carbide geared more towards steel? (longer tool life)

also, if my tools get dull how do I sharpen them? oil stone? (taig tools, preground HSS)

Tin Falcon

Well-Known Member

- Joined

- Jul 9, 2007

- Messages

- 7,207

- Reaction score

- 787

speedy:

Carbides are geared for faster production longer tool life is certainly part of this equation

Keep in mind entire books have been written on cutting tool materials.

There are carbides for wood carbides for steel carbides for cast iron ect.

There are also many grades of tool steel the grades with cobalt mixed in will last longer on steel.

Read brians thread on tool grinding. grab a few blanks grind then up hone them and try to cut with them.

Also read this http://www.metalwebnews.com/machine-tools/CH7.PDF it may answer a bunch of basic questions.

Tin

Carbides are geared for faster production longer tool life is certainly part of this equation

Keep in mind entire books have been written on cutting tool materials.

There are carbides for wood carbides for steel carbides for cast iron ect.

There are also many grades of tool steel the grades with cobalt mixed in will last longer on steel.

Read brians thread on tool grinding. grab a few blanks grind then up hone them and try to cut with them.

Also read this http://www.metalwebnews.com/machine-tools/CH7.PDF it may answer a bunch of basic questions.

Tin

Tin I read the link but nothing about sharpening (unless I completely missed it)

can I use stones you sharpen knives with (double sided oil stone, not sure the name)

I used the lathe today! had to clean up some plastic material for a R/C project. man is it addicting :big:

I was having so much fun that I messed up some measurements (very minor), but nothing that will effect my project.

now onto tools again. (if you remember my post on all those new starrett tools)

with plenty of back and forth emails with the seller, he is offering me a smaller package

"12'' electronic caliper

1'' electroninc indicator

mag.base w/ fine adjustment

tap wrench, taps and a center drill

3' square, 6" level, small rule set

Tape measure, 24" straight edge

(most include cases)

I'll throw in for free: Starrett note pad, englich-metric conversion card and tap drill size card and oil."

also some other small things.

I feel its a heck of a deal for 250 canadian

can I use stones you sharpen knives with (double sided oil stone, not sure the name)

I used the lathe today! had to clean up some plastic material for a R/C project. man is it addicting :big:

I was having so much fun that I messed up some measurements (very minor), but nothing that will effect my project.

now onto tools again. (if you remember my post on all those new starrett tools)

with plenty of back and forth emails with the seller, he is offering me a smaller package

"12'' electronic caliper

1'' electroninc indicator

mag.base w/ fine adjustment

tap wrench, taps and a center drill

3' square, 6" level, small rule set

Tape measure, 24" straight edge

(most include cases)

I'll throw in for free: Starrett note pad, englich-metric conversion card and tap drill size card and oil."

also some other small things.

I feel its a heck of a deal for 250 canadian

Tin Falcon

Well-Known Member

- Joined

- Jul 9, 2007

- Messages

- 7,207

- Reaction score

- 787

Speedy:

Probably a good deal

the above link does have tool and grinding info you just need to scroll down a few pages 7-5 to 7-10 .

Tin

Probably a good deal

the above link does have tool and grinding info you just need to scroll down a few pages 7-5 to 7-10 .

Tin

I did see the grinding parts, but I was more wondering about sharpening without grinding agian.

like with a stone.

I will look again. because I was also wondering what the proper ways are to put my tool bits in the holder.

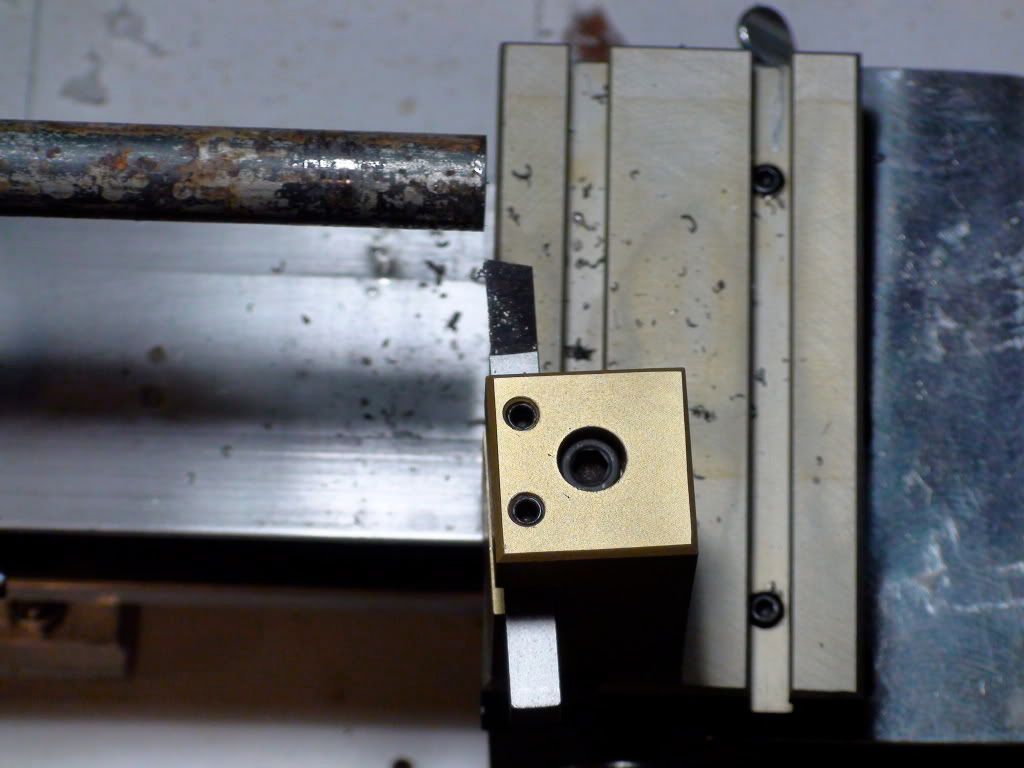

Deanofid's look like its on an angle. maybe because hes facing the inside (ugg I need to learn the proper terms! :big

I think im turning into a machine addict

like with a stone.

I will look again. because I was also wondering what the proper ways are to put my tool bits in the holder.

Deanofid's look like its on an angle. maybe because hes facing the inside (ugg I need to learn the proper terms! :big

I think im turning into a machine addict

Tin Falcon

Well-Known Member

- Joined

- Jul 9, 2007

- Messages

- 7,207

- Reaction score

- 787

Sorry speedy no pictures of how to stone the bits just hold them to the stone if done on the wheel a bit will be hollow ground the cutting edge and heel of each face will touch the wet/oil stone that is all you need . just hone the cutting edge and the heel a litle the middle of the bit may not be touched by the oil stone that is ok.

Tin

Tin

Speedy, the price of the tools looks pretty good if it's all Starret, but give some thought to the use of them. I don't know what machines you have, but if it's just the Taig, you probably won't have any use for the level or the 24" straight edge. Also, the 12" caliper is pretty long for working on small stuff. A 6" length will be a lot handier for use on a small lathe, unless you foresee a need to measure longer items with .001" accuracy.

Just my two bits.

Dean

Just my two bits.

Dean

hi Dean.

its all Starret and all bran new.

sorry the caliper is 8'' (forgot to update my post). I do have a 6 inch but it sometimes gets close to maxing out so the 8'' will be handy.

I was asking to do a trade for something else instead of the level and the 24'' straight edge but he was just throwing those in (both of those are over 100 new, from my research)

I am planning on getting a mill.

and if I can find some actual bigger machines then I will upgrade. (got the taig for a good price so I wont feel to bad)

its all Starret and all bran new.

sorry the caliper is 8'' (forgot to update my post). I do have a 6 inch but it sometimes gets close to maxing out so the 8'' will be handy.

I was asking to do a trade for something else instead of the level and the 24'' straight edge but he was just throwing those in (both of those are over 100 new, from my research)

I am planning on getting a mill.

and if I can find some actual bigger machines then I will upgrade. (got the taig for a good price so I wont feel to bad)

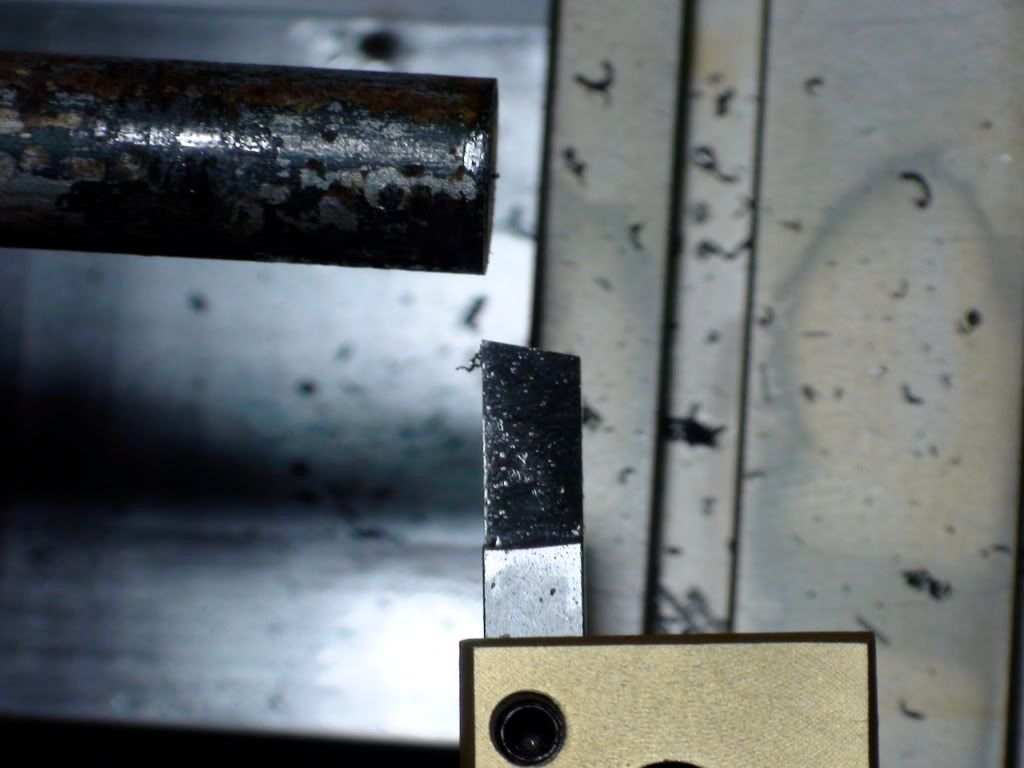

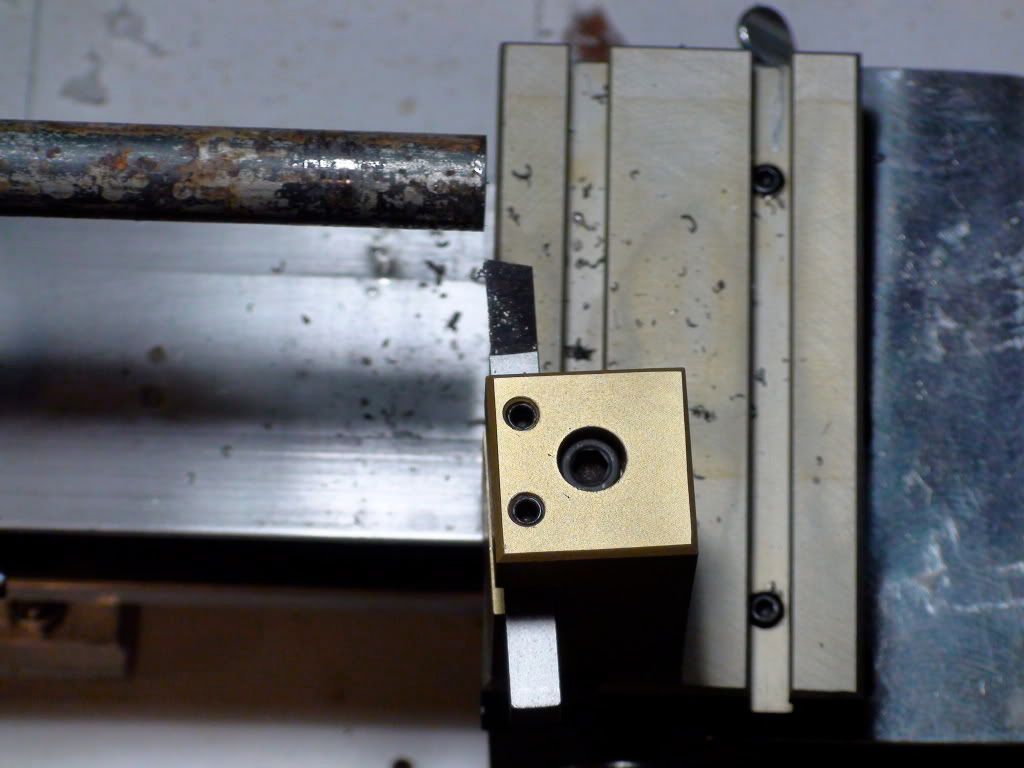

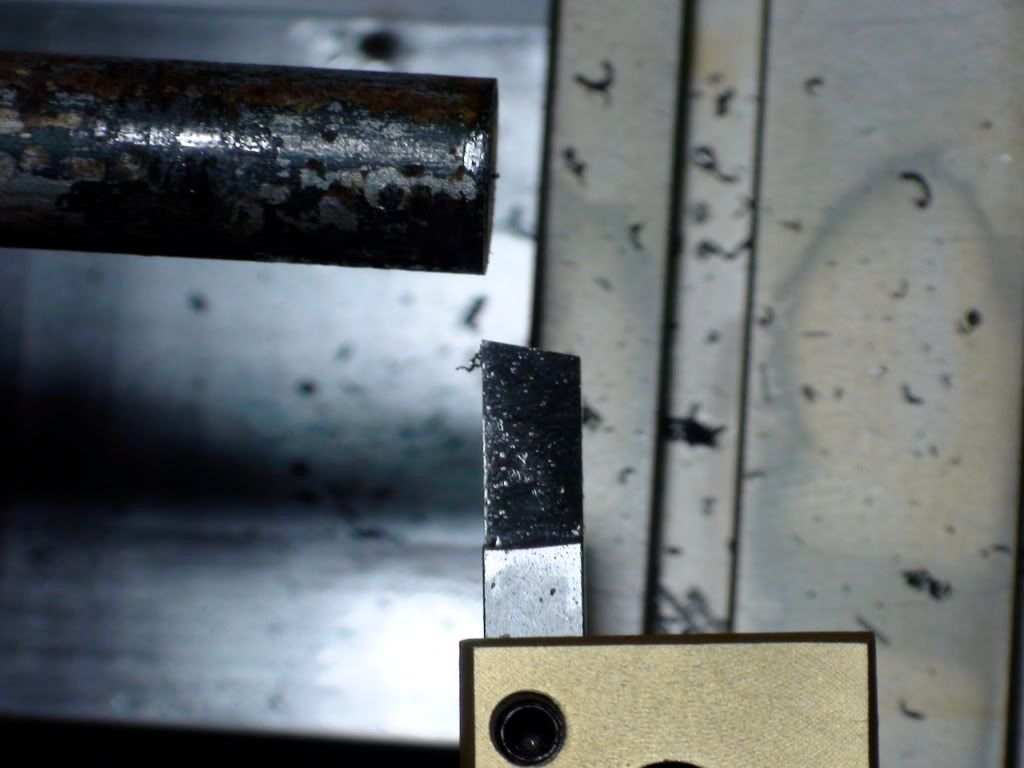

okay first attempt at mystery steel.

looks like I know how to make a prop nut!

from the look of this steel can anyone identify it?

tried 500rpm then 800rpm but no success, I got these speeds of sherlines website videos.

sure didnt cut as nice as the plastic yesterday :big:

** edit, forgot to mention I need to shim my tool slightly, its leaving a small nub.

looks like I know how to make a prop nut!

from the look of this steel can anyone identify it?

tried 500rpm then 800rpm but no success, I got these speeds of sherlines website videos.

sure didnt cut as nice as the plastic yesterday :big:

** edit, forgot to mention I need to shim my tool slightly, its leaving a small nub.

mklotz

Well-Known Member

You've got your workpiece sticking way too far out of the chuck. A reasonable rule of thumb is that the work should project no more than twice its diameter from the chuck.

Speedy said:okay first attempt at mystery steel.

looks like I know how to make a prop nut!

from the look of this steel can anyone identify it?

tried 500rpm then 800rpm but no success, I got these speeds of sherlines website videos.

sure didnt cut as nice as the plastic yesterday :big:

That cut looks familiar

A steady rest me thinks is in order. Skinny bar hanging out from chuck will just flex all over the place and once that chatter starts . . . at least for me, unless I can get the piece held ridged it just wont go away.

Robert

Similar threads

- Replies

- 86

- Views

- 20K