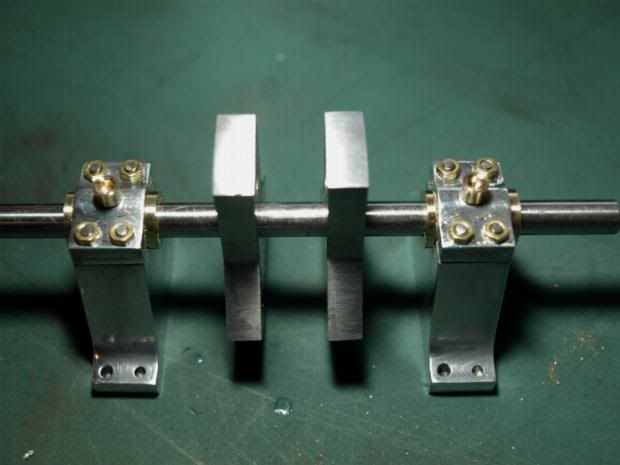

Being new to using a mill and lathe, I bought a casting kit to start with. Well after making a mistake on one of the castings right off, decided to learn more about machining by making parts from bar stock. That way as I make a mistake can just use more bar stock to redo it. I must say though, one call to PMR about replacing the casting I ruined, and it was in the mail to me same day. Nice customer service.

There really is no plans for this engine, roughly followed one from Rudy Kouhoupt's book but changed somethings more to my liking. Of course the pile of "not good enough" parts seem to be larger than the pile of parts to use but am learning.

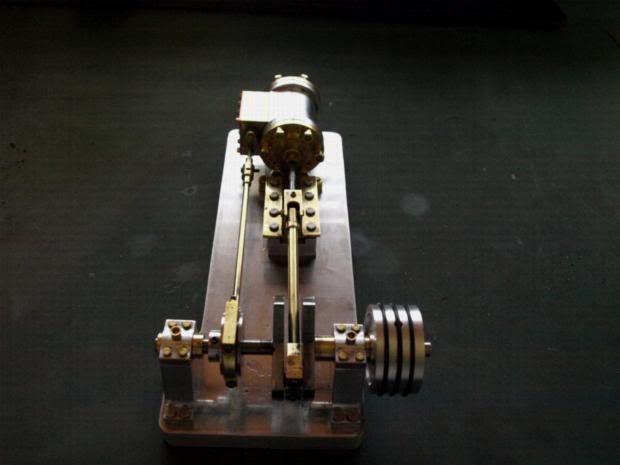

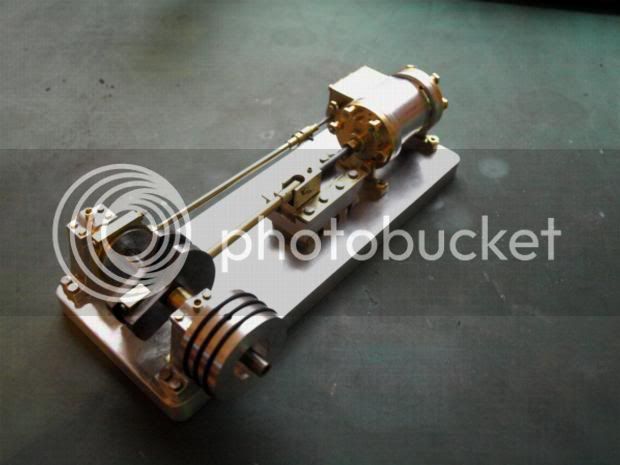

Anyway this is as far as I have gotten so far, and happy with what I have done and learned. Thanks for all those who post here as it helps to see what and how others do things.

There really is no plans for this engine, roughly followed one from Rudy Kouhoupt's book but changed somethings more to my liking. Of course the pile of "not good enough" parts seem to be larger than the pile of parts to use but am learning.

Anyway this is as far as I have gotten so far, and happy with what I have done and learned. Thanks for all those who post here as it helps to see what and how others do things.