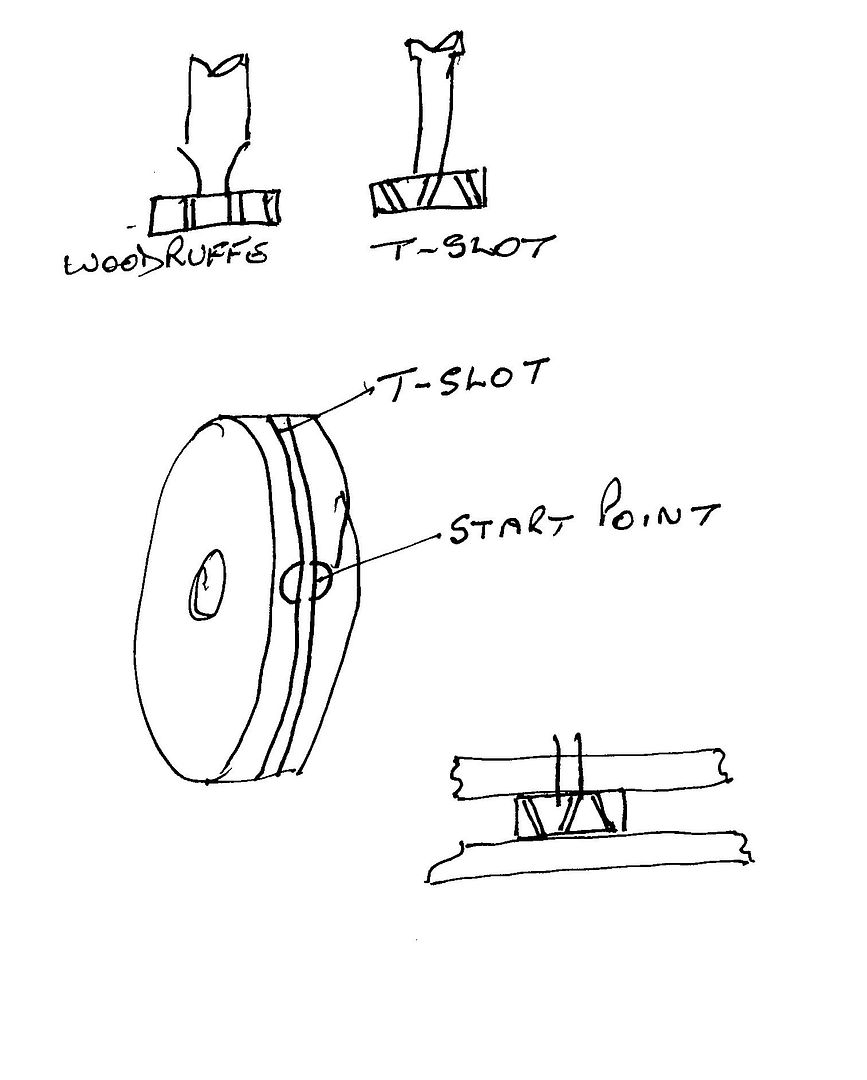

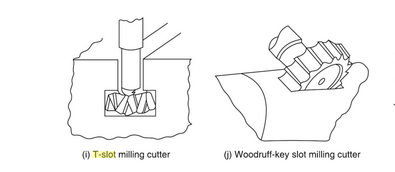

I have been looking for these for many years as although I can make a straight woodruffe cutter, I can't make the offset tooth type to carry out a job on a piece of tooling I need to make, putting a small T-slot around the outside edge of a disc.

These are 10mm and 12mm cutters, the thinnest being 2mm, ideal for what I need to do, and the cost was small compared to larger ones. They look to be well ground and I don't doubt they will cut cast iron just fine.

I only ordered these ten days ago, so very quick delivery.

http://www.aliexpress.com/item/Free...aight-shank-T-groove-milling/32336440928.html

http://www.aliexpress.com/item/Free...aight-shank-T-groove-milling/32336520555.html

Plus if anyone is looking for a decent quality chuck for their Dremel, I have four of these for use on my Dremel type tooling.

http://www.aliexpress.com/item/mini....html?spm=2114.10010108.1000015.42.EoPspC&s=p

This information may be of use to someone

John

These are 10mm and 12mm cutters, the thinnest being 2mm, ideal for what I need to do, and the cost was small compared to larger ones. They look to be well ground and I don't doubt they will cut cast iron just fine.

I only ordered these ten days ago, so very quick delivery.

http://www.aliexpress.com/item/Free...aight-shank-T-groove-milling/32336440928.html

http://www.aliexpress.com/item/Free...aight-shank-T-groove-milling/32336520555.html

Plus if anyone is looking for a decent quality chuck for their Dremel, I have four of these for use on my Dremel type tooling.

http://www.aliexpress.com/item/mini....html?spm=2114.10010108.1000015.42.EoPspC&s=p

This information may be of use to someone

John

Last edited: