DickDastardly40

Well-Known Member

- Joined

- Oct 23, 2007

- Messages

- 309

- Reaction score

- 0

You know the adage when the only tool you have is a hammer, everything looks like a nail, well my new to me VMC mill arrived (pics to follow) and I am playing.

Where I would have parted something previously, I'd like to use the mill and slit so as to get less waste.

I have never been taught to use a slit saw and bought one on a whim a while ago, so this is it's first tryout.

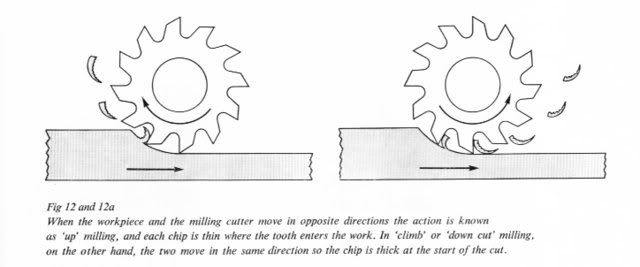

What formula should I use for speed/feed and what depth of cut is recommended as regards tooth size. Is feeding into the blade (upcut) a la a circular saw verboten as this is essentially climb milling?

Any advice gratefully received even links to previous threads, I've never seen anything written about slitting.

Al

Where I would have parted something previously, I'd like to use the mill and slit so as to get less waste.

I have never been taught to use a slit saw and bought one on a whim a while ago, so this is it's first tryout.

What formula should I use for speed/feed and what depth of cut is recommended as regards tooth size. Is feeding into the blade (upcut) a la a circular saw verboten as this is essentially climb milling?

Any advice gratefully received even links to previous threads, I've never seen anything written about slitting.

Al