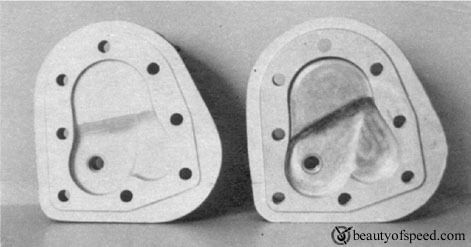

The timing figures for the Vega 30 are much wilder than your engine, ownthesky2010. http://modelenginenews.org/cardfile/vega30.html I think plug location would be the first thing to investigate. Being side valve it simply won't make a ton of power. Anything you can do to make it run better than it is, should make a little more power. In the video it seems pretty rich, but that could be poor combustion due to plug location. You want to try to get the plug centered to the chamber. Later Ricardo chambers put the plug over the exhaust valve to reduce knock, but I don't think knock will be much of an issue here. Opening the passage to the cylinder would be worth trying. I would think compression ratio shouldn't have much effect, unless it's knocking.

How much oil is there in the fuel you're using?

Greg

How much oil is there in the fuel you're using?

Greg