You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Shop-made tools

- Thread starter ksouers

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

B

Bogstandard

Guest

No good for me John, that is a left handed one.

Bogs

Bogs

John Stevenson said:Instead of making a holder use the straight end of one of those cheap boring tools.

The type where you get one square at 90 degrees and the other at 45 degrees.

John,

My brain is not working at peak efficiency today .......... can I have a picture

Ta

Maryak

Well-Known Member

- Joined

- Sep 12, 2008

- Messages

- 4,990

- Reaction score

- 77

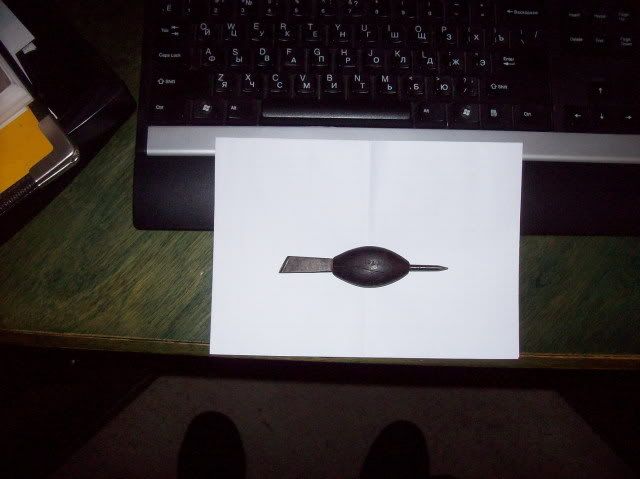

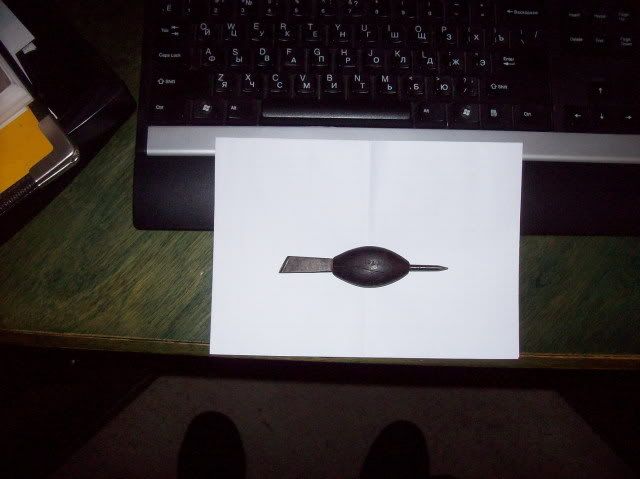

Was looking for an old wood chisel, (Don't ask : ) and came across this gizmo in the photo.

) and came across this gizmo in the photo.

Looking at the name stamped in the wooden handle which is possibly ebony, I think it was my Great Great Grandfathers and thus mid 19th Century.

Any ideas what it may be ??? ??? ??? Point at one end wood type chisel at an angle at the other.

Regards

Bob

Looking at the name stamped in the wooden handle which is possibly ebony, I think it was my Great Great Grandfathers and thus mid 19th Century.

Any ideas what it may be ??? ??? ??? Point at one end wood type chisel at an angle at the other.

Regards

Bob

Bob, have something very similar but not ebony (

it was used with veneers for intricate veneer work

i used it as a leather engraver but the original usage was veneer work i forget the name sorry.

grandafther was a very high level art deco furniture maker in his day

cheers

jack

it was used with veneers for intricate veneer work

i used it as a leather engraver but the original usage was veneer work i forget the name sorry.

grandafther was a very high level art deco furniture maker in his day

cheers

jack

Maryak

Well-Known Member

- Joined

- Sep 12, 2008

- Messages

- 4,990

- Reaction score

- 77

Thanks Jack,

That fits with what I know about him, I still have his old wooden planes and chisels and in the UK at my cousins home is a large dresser type thing all made without nails or screws, just wooden pegs and dovetail joints.

Regards

Bob

That fits with what I know about him, I still have his old wooden planes and chisels and in the UK at my cousins home is a large dresser type thing all made without nails or screws, just wooden pegs and dovetail joints.

Regards

Bob

K

Kludge

Guest

John Stevenson said:I modified these to make them more accurate and swap easily from imperial to metric.

Well, now we know who's selling them on eBay. ;D

BEst regards,

Kludge

Bluechip

Well-Known Member

- Joined

- Jun 21, 2008

- Messages

- 228

- Reaction score

- 0

Hi Bob

The flat bit is a scribing/marking knife. Used across grain with a square, avoiding fingers preferably , to mark a joint.

Cuts the into the grain so it doesn't tear when joint is sawn.

Still common in joinery.

I've got one.

Not as posh as that tho'.

Mines similar to this, only cheaper

http://www.axminster.co.uk/product.asp?pf_id=21839&name=marking+knife&user_search=1&sfile=1&jump=0

dave

The flat bit is a scribing/marking knife. Used across grain with a square, avoiding fingers preferably , to mark a joint.

Cuts the into the grain so it doesn't tear when joint is sawn.

Still common in joinery.

I've got one.

Not as posh as that tho'.

Mines similar to this, only cheaper

http://www.axminster.co.uk/product.asp?pf_id=21839&name=marking+knife&user_search=1&sfile=1&jump=0

dave

Maryak

Well-Known Member

- Joined

- Sep 12, 2008

- Messages

- 4,990

- Reaction score

- 77

MattMoore,

Thanks for further enlightenment on my little find. :bow:

They new much more than we give them credit for didn't they.

I found and old, (early 1900's), book about making piston rings and then a paper on the internet about piston ring tribology, with umpteen nifty formula for calculating the ring blank dimensions.

The 1900's book talked in 1/64" terms and the other xxxxxx decimal places. When I compared one result with the other, they were within a few thou of each other

Thanks again, me and my ancestor can now rest in peace.

Regards

Bob

Thanks for further enlightenment on my little find. :bow:

They new much more than we give them credit for didn't they.

I found and old, (early 1900's), book about making piston rings and then a paper on the internet about piston ring tribology, with umpteen nifty formula for calculating the ring blank dimensions.

The 1900's book talked in 1/64" terms and the other xxxxxx decimal places. When I compared one result with the other, they were within a few thou of each other

Thanks again, me and my ancestor can now rest in peace.

Regards

Bob

Your Ancestor perhaps Bob :Maryak said:Thanks again, me and my ancestor can now rest in peace.

CC

jrlandau

Member

I'm shooting for the "grungiest tool" award ;D: this is a buffer I made when I noticed that a defunct electric motor still has 2 bearings a foot or so apart, and right in line. So I threw out the armature, cut a hole in the housing for a belt, and made a nice shaft with a RH thread on one end and a LH on the other. Maybe the most-used tool in my shop.

Similar threads

- Replies

- 0

- Views

- 557