- Joined

- Feb 25, 2008

- Messages

- 464

- Reaction score

- 5

Hello Everyone,

This is my first post. I've been a lurker for quite some time. I was encouraged to post by mklotz, who I met at a local swap meet where the SCHSM had a display set up, and by 1kenny who sent me a private message encouraging me to post after seeing my video on YouTube. Up until about six months ago, I considered myself a woodworker. Then I ran across this site and got the machining bug. Virtually everything I've learned has come from this site...you guys are great! I know I would never have thought of attempting this engine until I saw Bogstandard's treatise on building crankshafts.

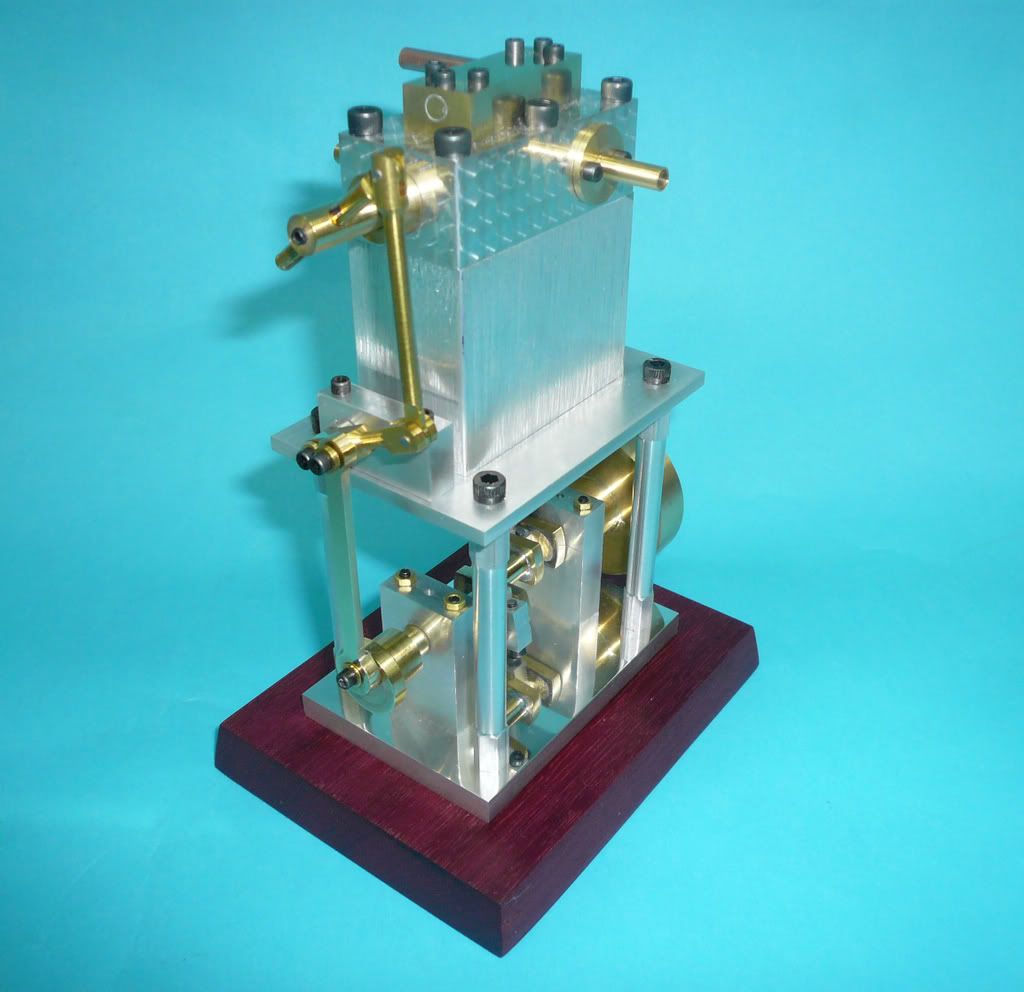

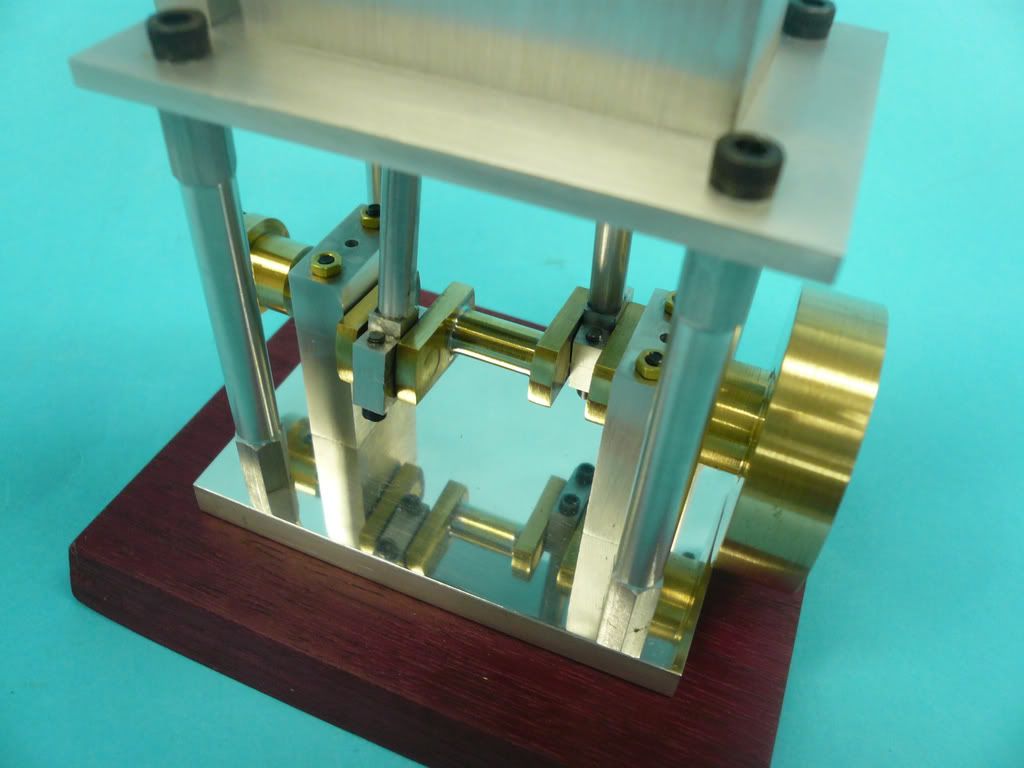

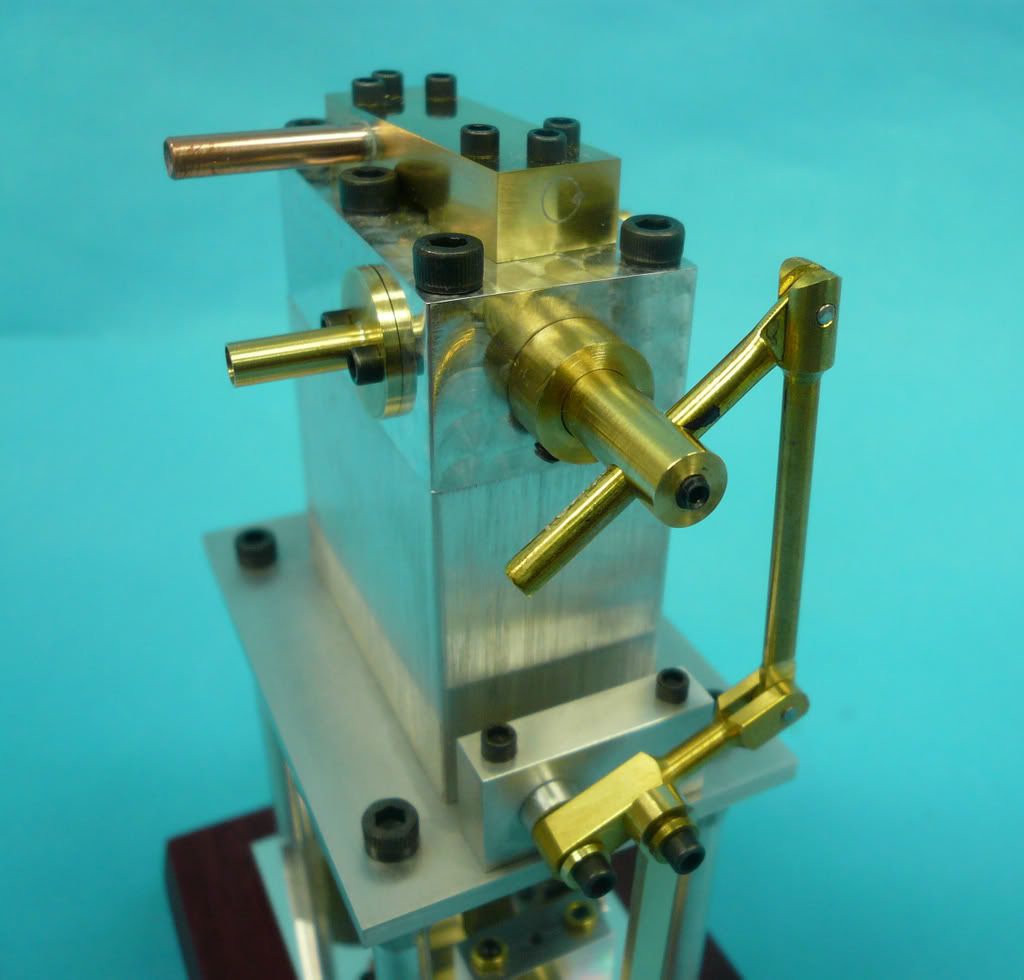

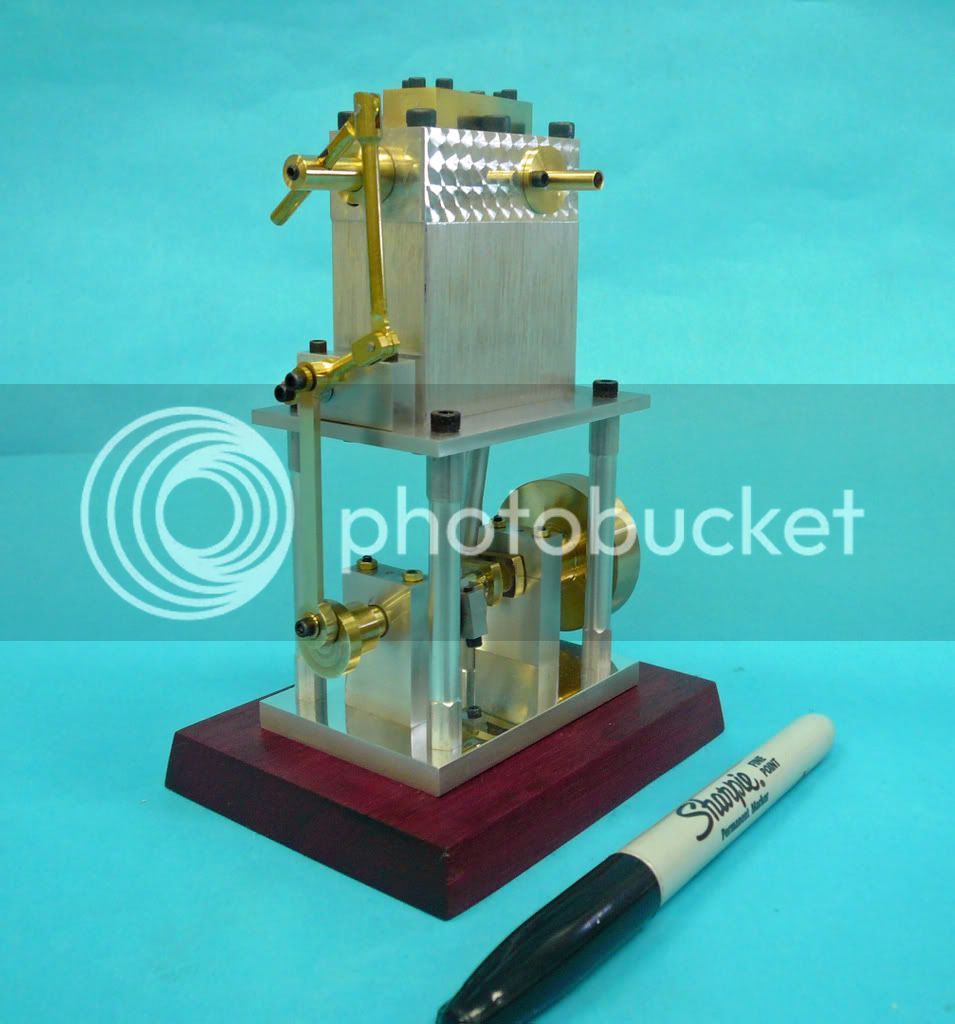

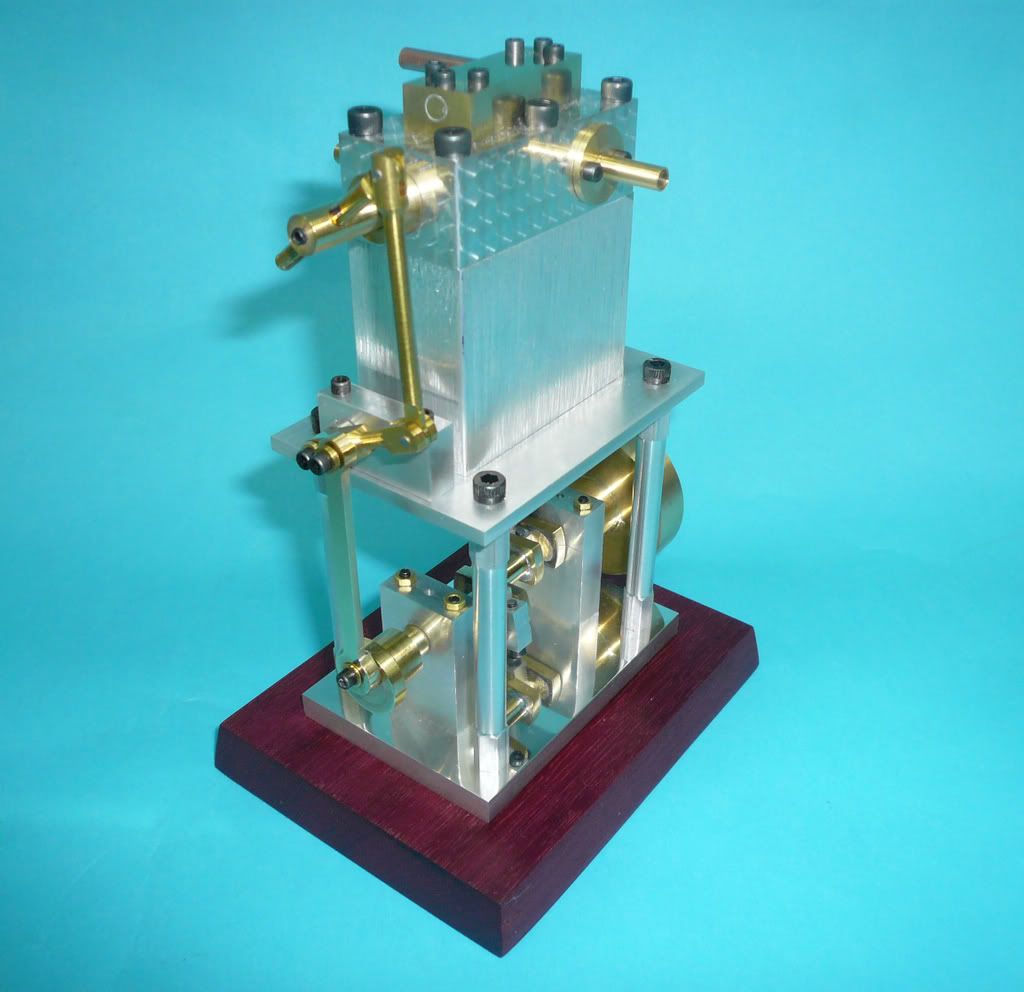

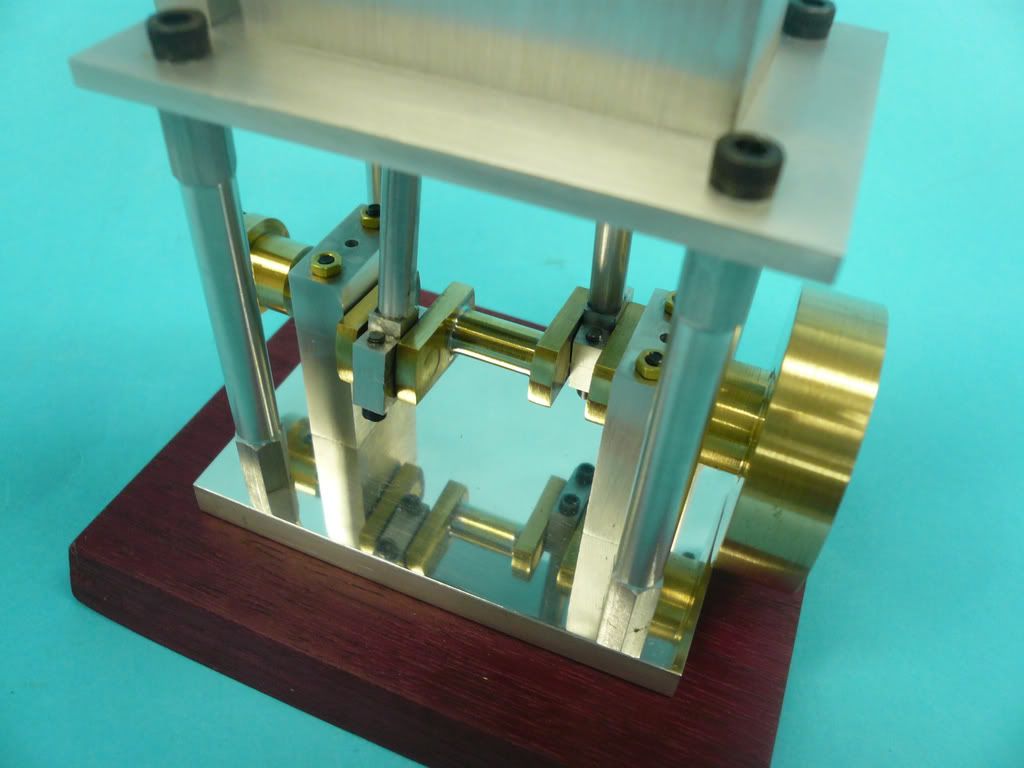

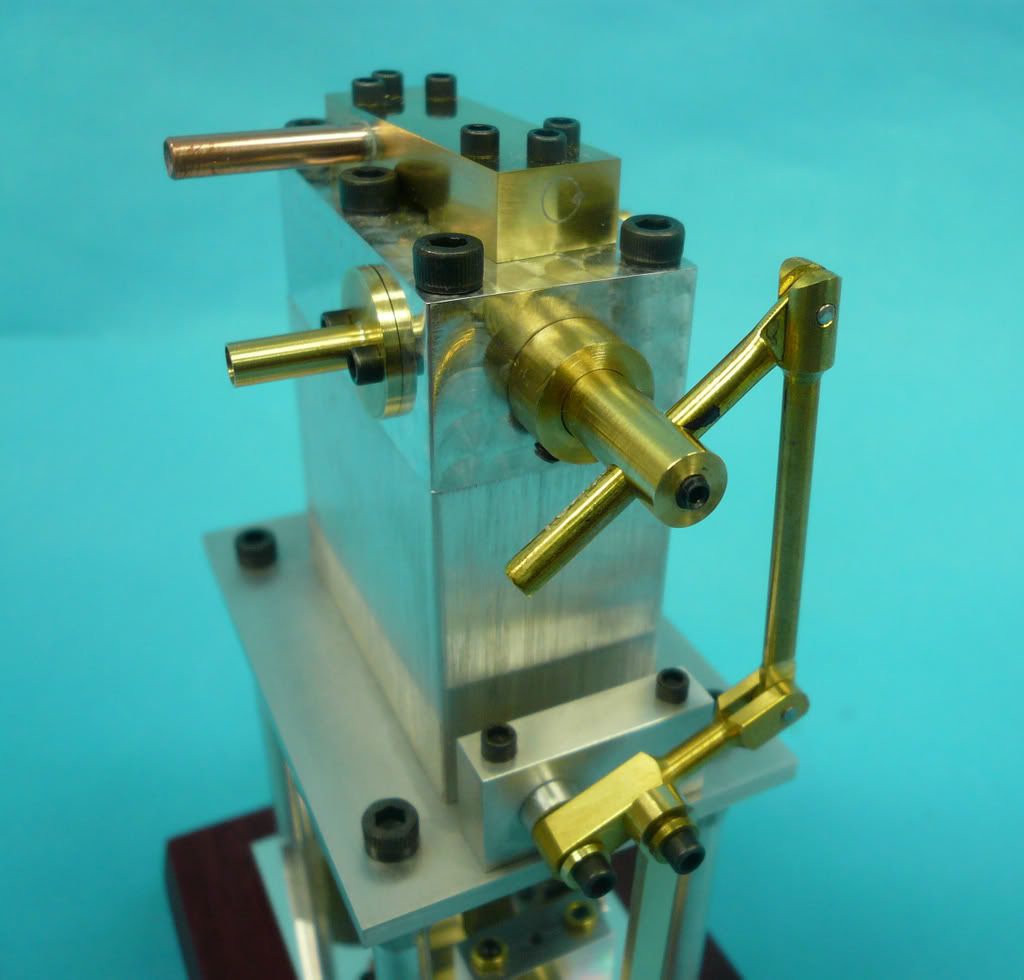

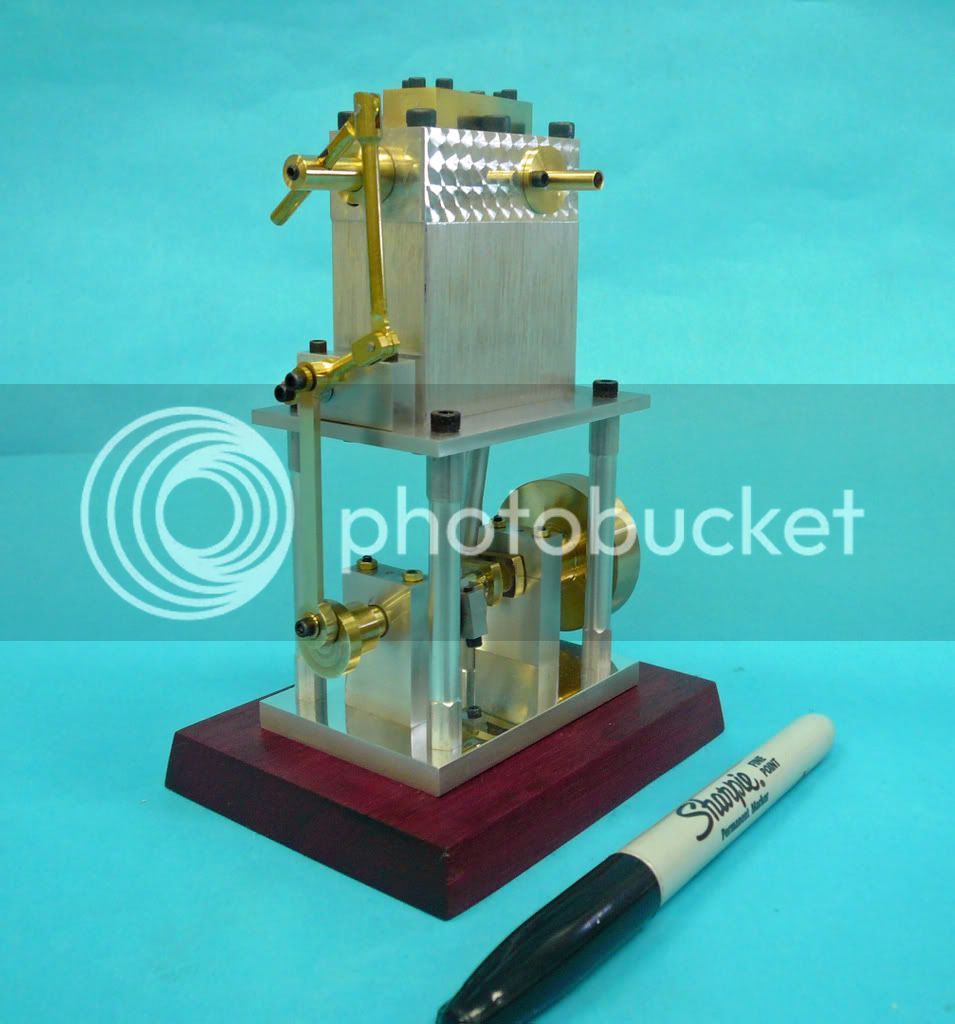

Following are some photos of my second engine (and second machining project). I wish I had taken some "in-process" photos.

This is a model of a two cylinder vertical marine engine with a 7/16" stroke and 9/16" bore. It's made from bar stock using plans from the John-Tom site. There are a few modifications such as the intake manifold and some dimensional changes. Nothing too major though. The model is 5 1/2" tall and the aluminum base is 2"x3".

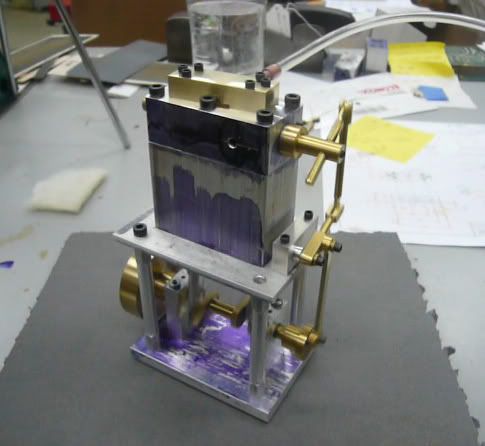

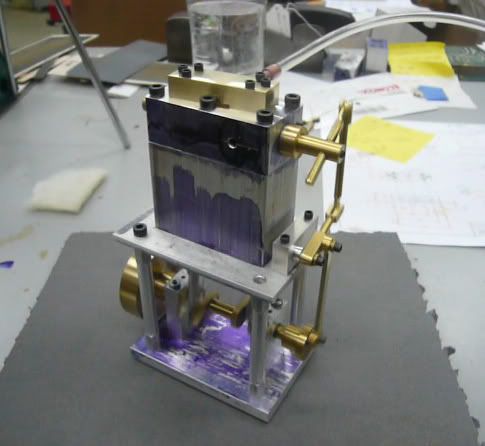

The following is a photo of the engines first run....another super tip from this site. Make sure it works before you start polishing!!

Here's a shot of it running (You need to get about 20 seconds in before I turn on the air). It's running on a little less than 7 PSI.

[ame]http://www.youtube.com/watch?v=tiOldErjsoI[/ame]

In case you're wondering, this was my first project. Nice, but not nearly as fun to watch as the two cylinder. Also, I think the timing may be off a bit because of that knock.

[ame]http://www.youtube.com/watch?v=phsJPLoffIE[/ame]

This is my first post. I've been a lurker for quite some time. I was encouraged to post by mklotz, who I met at a local swap meet where the SCHSM had a display set up, and by 1kenny who sent me a private message encouraging me to post after seeing my video on YouTube. Up until about six months ago, I considered myself a woodworker. Then I ran across this site and got the machining bug. Virtually everything I've learned has come from this site...you guys are great! I know I would never have thought of attempting this engine until I saw Bogstandard's treatise on building crankshafts.

Following are some photos of my second engine (and second machining project). I wish I had taken some "in-process" photos.

This is a model of a two cylinder vertical marine engine with a 7/16" stroke and 9/16" bore. It's made from bar stock using plans from the John-Tom site. There are a few modifications such as the intake manifold and some dimensional changes. Nothing too major though. The model is 5 1/2" tall and the aluminum base is 2"x3".

The following is a photo of the engines first run....another super tip from this site. Make sure it works before you start polishing!!

Here's a shot of it running (You need to get about 20 seconds in before I turn on the air). It's running on a little less than 7 PSI.

[ame]http://www.youtube.com/watch?v=tiOldErjsoI[/ame]

In case you're wondering, this was my first project. Nice, but not nearly as fun to watch as the two cylinder. Also, I think the timing may be off a bit because of that knock.

[ame]http://www.youtube.com/watch?v=phsJPLoffIE[/ame]