Cheers Jim/Pete/Eric

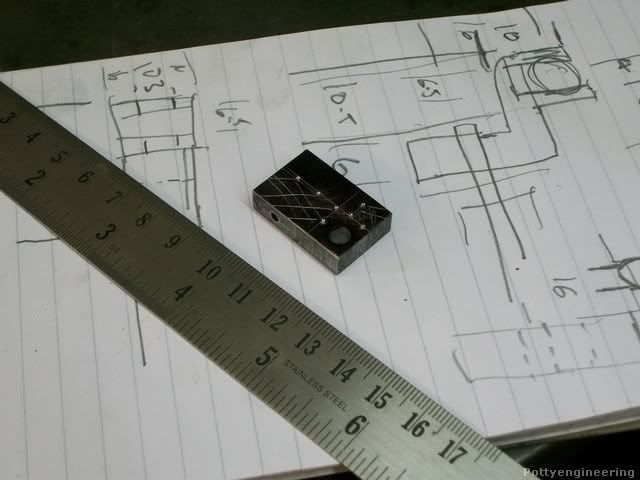

The butterfly valve is based on a tubal Cain design in his book "Building the Beam Engine Mary" that I've adapted and metricated for this engine.

First part the main body just a simple turning job.

Mount it in the mill vice find its centre in the X and Y and mill a 10mm dia flat with a 2mm hole 4mm deep in the middle.

Turn up a little nugget of brass with a 2mm nipple to locate in the body.

Silver solder the two together mount back in the vice with the nugget horizontal, and skim it off flat the drill 3mm through into the hole and a little way through the other side, and drill and tap 1/4"*40 ME.

Mount the other way round sitting on a parallel and in the vice gripping on the flat face, find the centre of the hole using the coaxial indicator, and drill the four bolting down holes using the DRO, make sure you get them oriented the correct way.

The boss floated off line when I soldered it, but I think it gives it that just cast look, :big:

The butterfly sits at a 30 angle across the air way which means its has an oval shape, this is the way Tubal Cain made the butterfly which I think is real neat. Mill a 30 deg angle across a bit of brass bar.

Soft solder the brass shim that will form the butterfly on the end.

Turn the bar down to 6mm.

Heat the bar up again so that the butterfly drops off, clean it up and you've got an oval.

Now wasn't that neat ;D

Stew