Hi Chuck and Jim, the tap is held in place with a grub screw (other side of the tool) as its only a small tap driver it doesnt need a heap of clamping power. I thought about using 2 screws, each side of the tap drive flates but instead ran one straight onto the shaft.

the stuff was all scrap from the "I wont throw that away box...". The tap holder itself was a piece of 12mm bright steel rod, I think you guys call this drill rod?? Not sure about that...

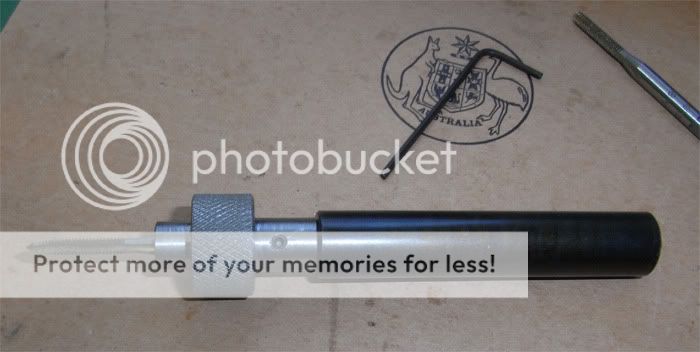

The 13mm plate for the 'handle' was a random piece of square which I centred, drilled for interference fit on the tap holder shaft. I then drilled the holder for the tap, tapered the end and pressed it into the handle.

Here's where I got paranoid and silver soldered the finger plate to the tap holder. It was a tight fit and this operation was not required..ah well... what would I have said if it ever started to slip?

Then chucked it all in the lathe and turned the finger plate to a round profile (I hate that bit, turning square edges into round) and knurled the finger edge.

I found a piece of reasonably heavy wall tubing which I drilled for a clearance hole on the tap holder shaft and cleaned up the scale on the outter surface. This mounts in the mill and guides the tap holder square etc. This is a pretty loose fit as its only a guide and needs no friction.

Guide tube and finger grip are mild steel. It all only took about an hour and is just another addition to my range of 'miniature' tooling...

Got another little piece which I use a fairly often, will try and get pics up in a few days. Piece of 20mm square mild steel bar about 75mm long. I drilled it with a variety of holes along the centre line (12, 10, 8 and 6mm)and then split the whole thing down the centre.

Great for clamping round pieces of shaft in the vice for whatever operation.

Actually, before I add pics of that I'll remake it neater... :big: split it with a hacksaw cause I didnt have a slitting blade thin enough, after seeing the items you guys produce, Id call that a lil rough... ;D