You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

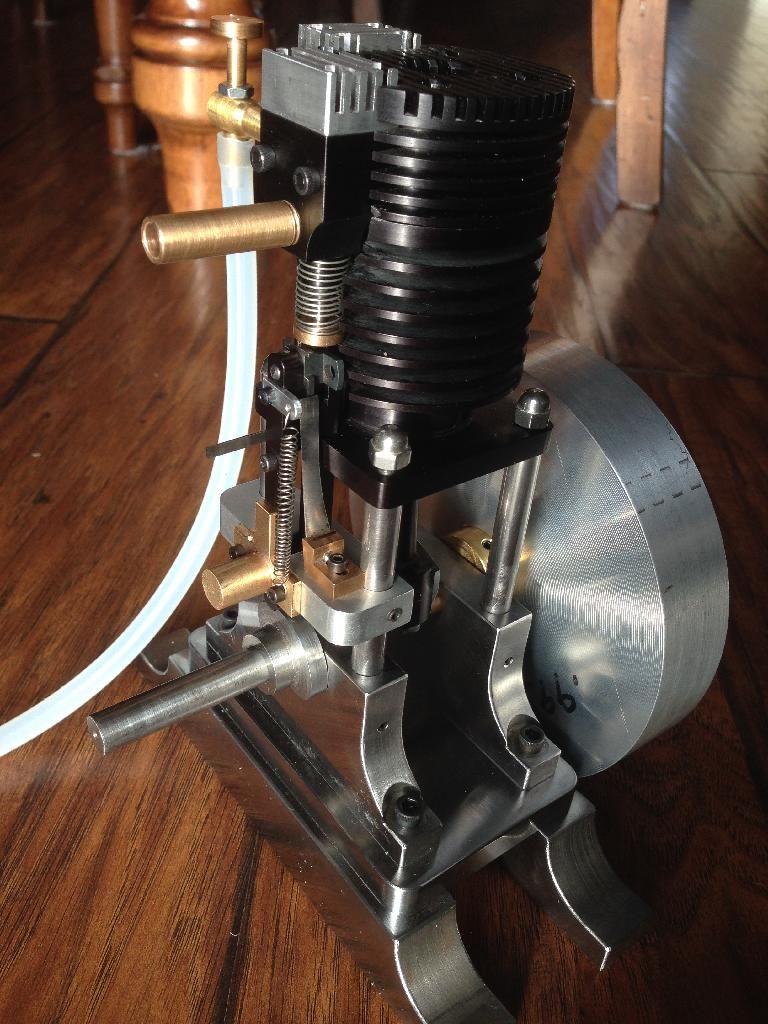

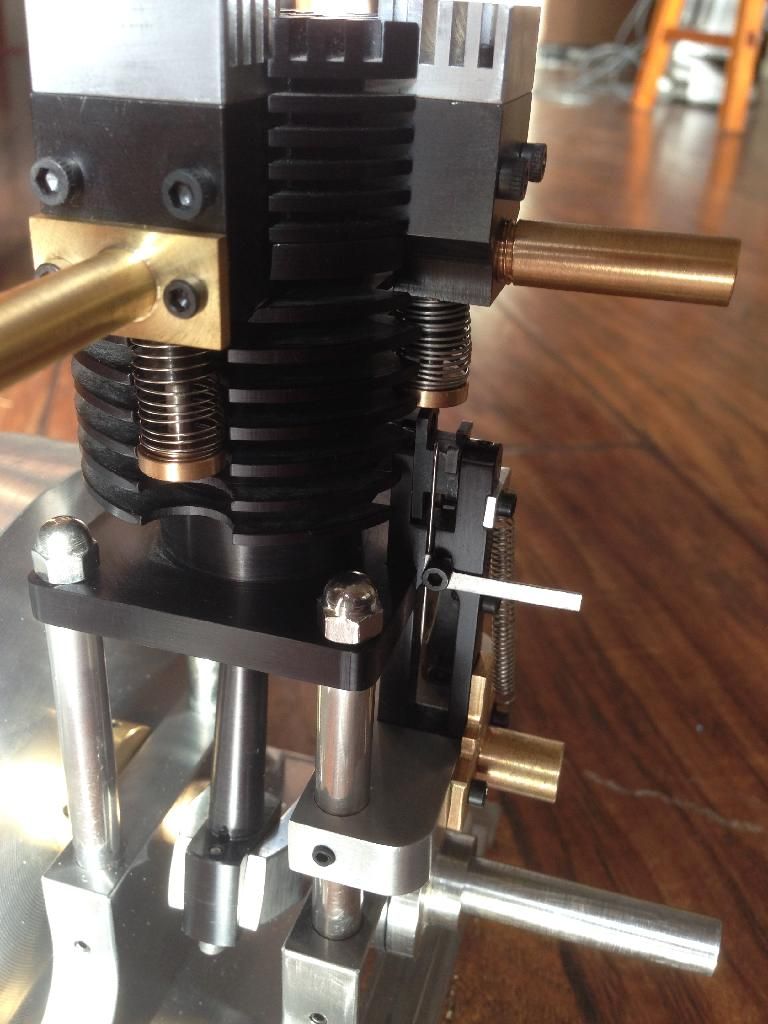

Philip Duclos Gearless Hit'n Miss Engine

- Thread starter Looper7

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Looper7

Well-Known Member

- Joined

- Dec 10, 2013

- Messages

- 51

- Reaction score

- 15

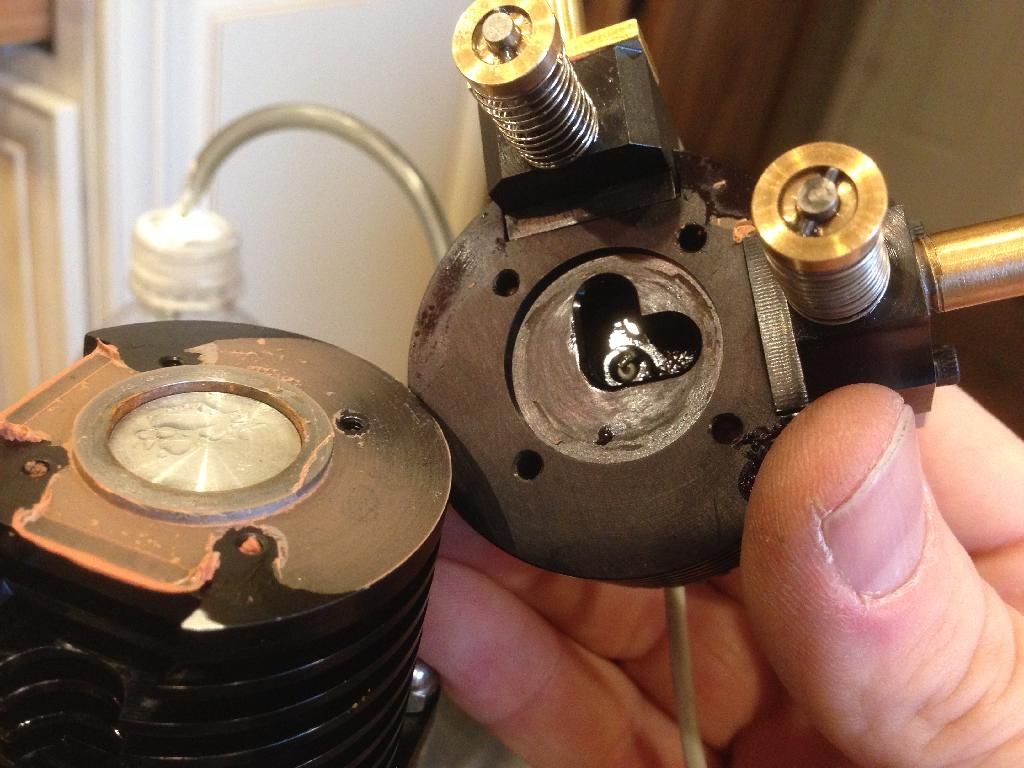

Well it looks like my pushrod is getting stuck I made the pillar shelf slot to .005 to big. And with the spring pulling to one side it gets stuck. Going to try 2 Springs 1 on each side.

[ame]http://youtu.be/cbrqZZrG2j8[/ame]

Sent from my iPhone using Model Engines

[ame]http://youtu.be/cbrqZZrG2j8[/ame]

Sent from my iPhone using Model Engines

Looper7

Well-Known Member

- Joined

- Dec 10, 2013

- Messages

- 51

- Reaction score

- 15

Looper7

Well-Known Member

- Joined

- Dec 10, 2013

- Messages

- 51

- Reaction score

- 15

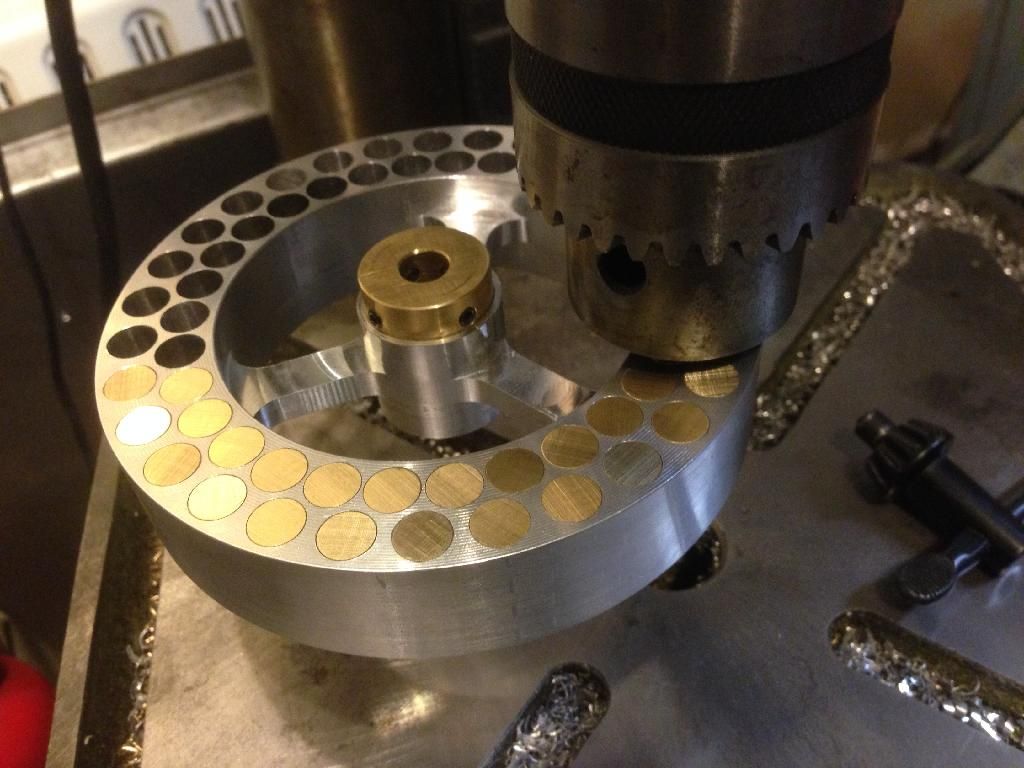

This is where I deviate from the print I have The flywheel on the opposite side so that One can see the magic.

I chose this engine at the beginning of my machining Occupation Because making gears scared me. 20 years later I still haven't machined a gear hope to change that in the future.

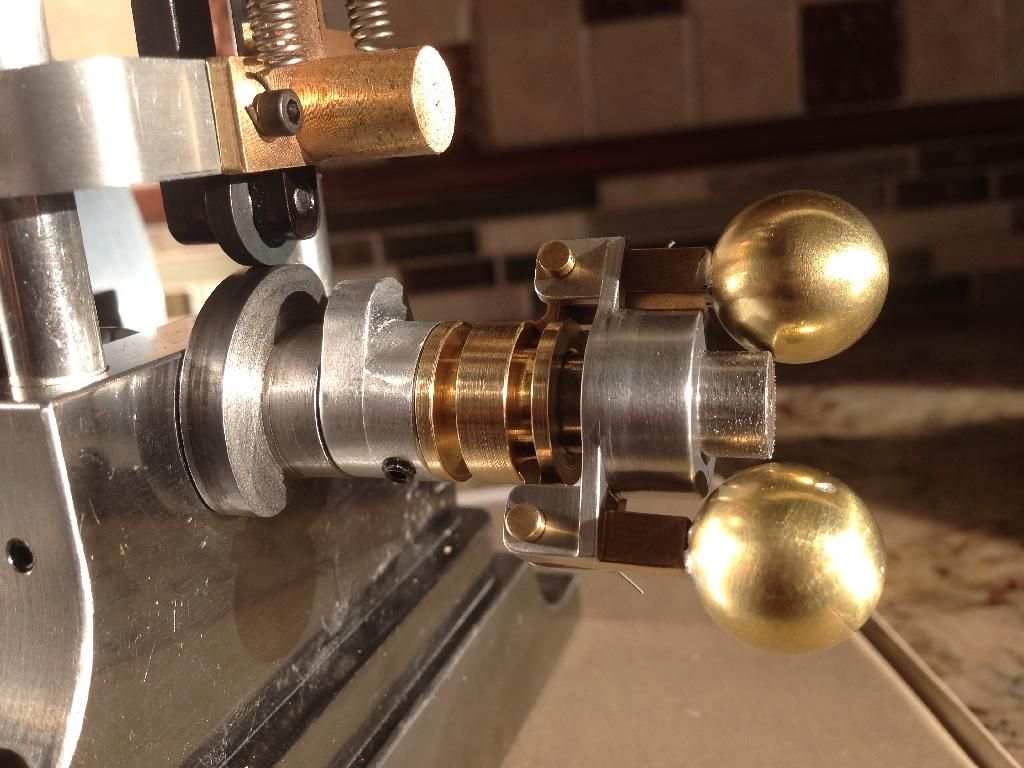

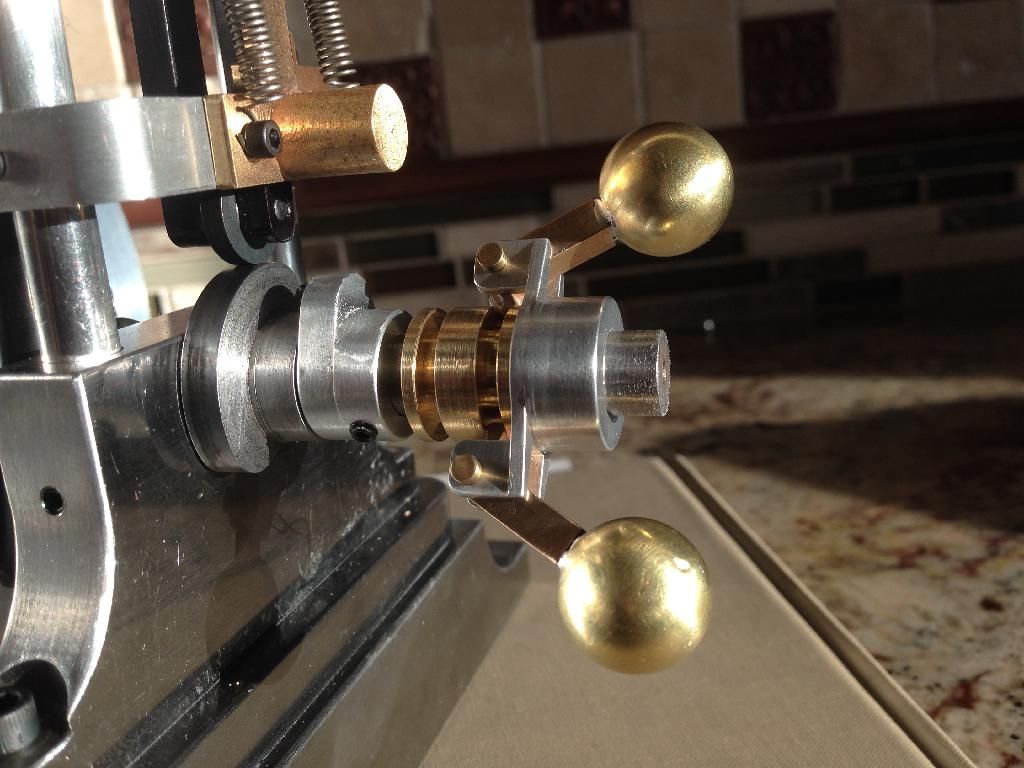

Using the governor balls from Philip Duclos Victorian engine before soldering I use white out a trick learned from Brian Rupnow. I should've clamped it in place with something that ball sure is hot.

I would like to thank the community for all the information that I've been able to glean from this site and for the inspiring photos

I'm getting excited will have a running engine soon. next I'm going to work on the arm of the governor.

Sent from my iPhone using Model Engines

I chose this engine at the beginning of my machining Occupation Because making gears scared me. 20 years later I still haven't machined a gear hope to change that in the future.

Using the governor balls from Philip Duclos Victorian engine before soldering I use white out a trick learned from Brian Rupnow. I should've clamped it in place with something that ball sure is hot.

I would like to thank the community for all the information that I've been able to glean from this site and for the inspiring photos

I'm getting excited will have a running engine soon. next I'm going to work on the arm of the governor.

Sent from my iPhone using Model Engines

Looper7

Well-Known Member

- Joined

- Dec 10, 2013

- Messages

- 51

- Reaction score

- 15

Nice build Looper. I'm glad that someone learned something from me.---Brian

Looper7

Well-Known Member

- Joined

- Dec 10, 2013

- Messages

- 51

- Reaction score

- 15

Thanks Brian. I enjoyed watching your opposed engine

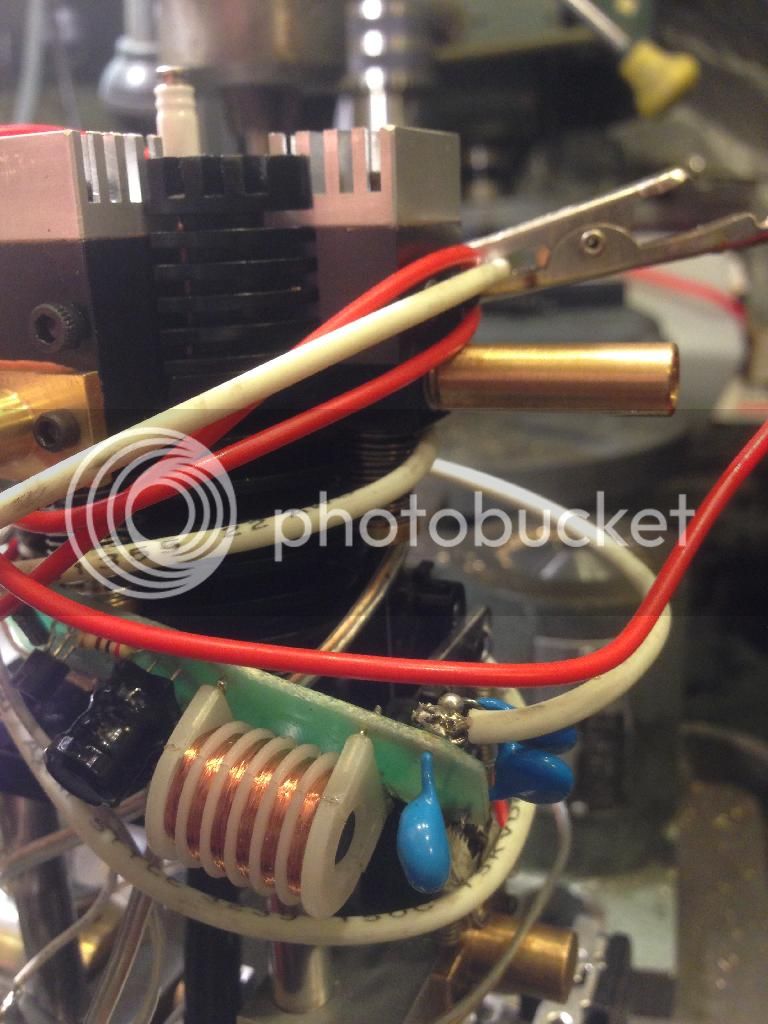

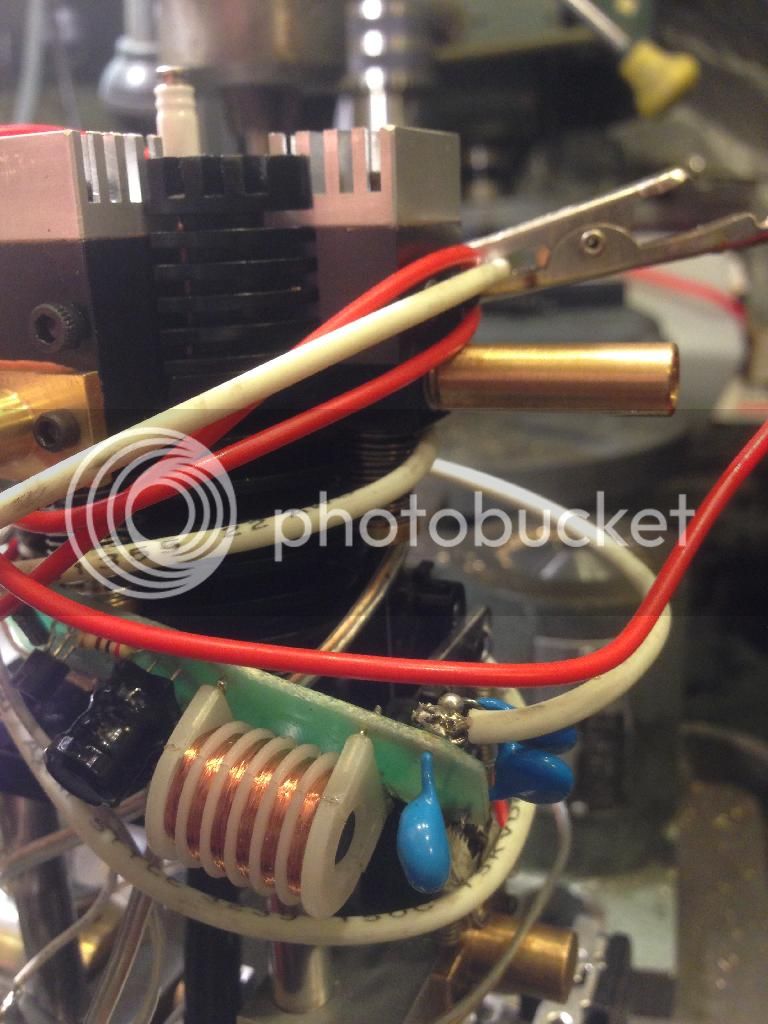

I have the spark working. I got some 6kv27p capacitors (blue M&Ms) on eBay. They make the Spark Hotter. And I increase my spark gap. Now I have to overcome friction and rework the flywheel aluminum is not as heavy as steel obviously. I am confident I will get it running unfortunately I'm going to have to put it on the shelf for little while.

Jeff Hickenlooper

I have the spark working. I got some 6kv27p capacitors (blue M&Ms) on eBay. They make the Spark Hotter. And I increase my spark gap. Now I have to overcome friction and rework the flywheel aluminum is not as heavy as steel obviously. I am confident I will get it running unfortunately I'm going to have to put it on the shelf for little while.

Jeff Hickenlooper

Looper7

Well-Known Member

- Joined

- Dec 10, 2013

- Messages

- 51

- Reaction score

- 15

For now I have bonded some shim stock in the slot to take up some of the gap. Going to have to make a new one it looks pretty bad. When I was taking apart I noticed lots rust in the cylinder and I have some quite a few scratches. Will make a note to put oil in the spark plug hole when I put it to bed

Jeff

Similar threads

- Replies

- 25

- Views

- 4K

- Replies

- 3

- Views

- 351