mklotz

Well-Known Member

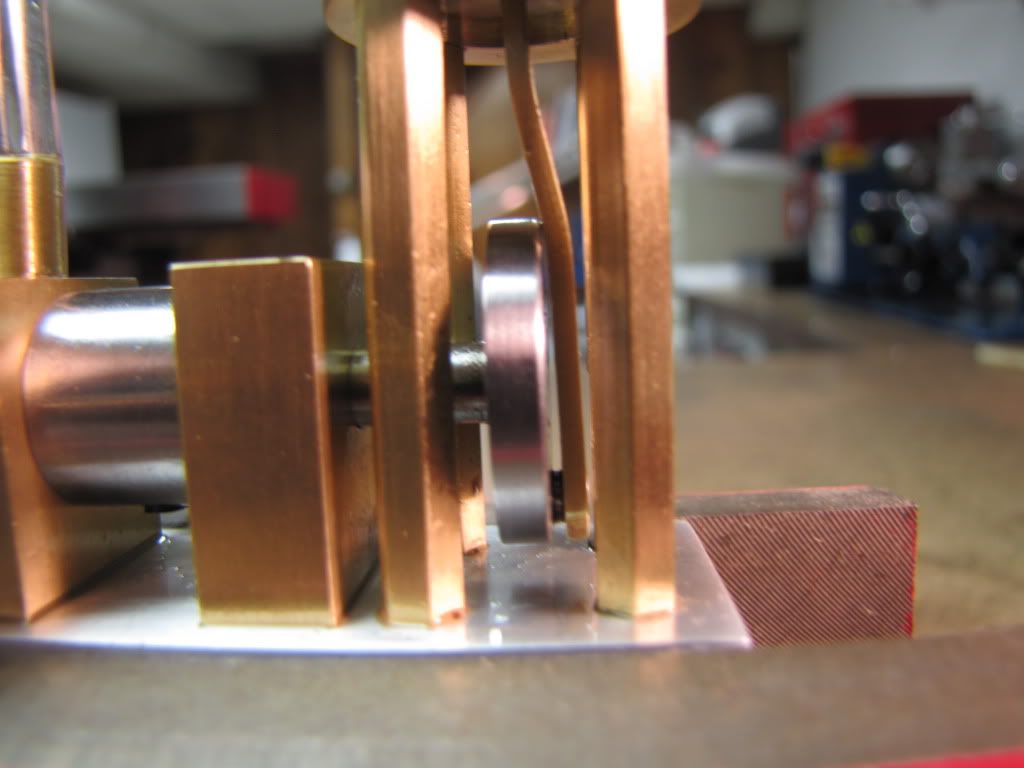

Since the valve position on the crank shaft is important (it determines valve phasing relative to piston position), are you certain that:

The flat on the crankshaft is properly placed relative to the pin that drives the connecting rod to the piston.

The setscrew in the valve is properly placed relative to the grooves in the valve.

The combination of those two determine proper valving operation. If either of those is fuggulated, it very likely can't run.

Stop fiddling with the piston/cylinder until the valving is sorted out. Occam's razor here.

Write the following in your shop notebook:

Don't commit on valve placement/orientation/etc. until the engine is running.

Next time you're at the hardware store, buy some lightweight oil to lubricate engines.

(Rea's Hardware (if they have them in the Keystone state) sells turbine oil.)

The flat on the crankshaft is properly placed relative to the pin that drives the connecting rod to the piston.

The setscrew in the valve is properly placed relative to the grooves in the valve.

The combination of those two determine proper valving operation. If either of those is fuggulated, it very likely can't run.

Stop fiddling with the piston/cylinder until the valving is sorted out. Occam's razor here.

Write the following in your shop notebook:

Don't commit on valve placement/orientation/etc. until the engine is running.

Next time you're at the hardware store, buy some lightweight oil to lubricate engines.

(Rea's Hardware (if they have them in the Keystone state) sells turbine oil.)