jrlandau

Member

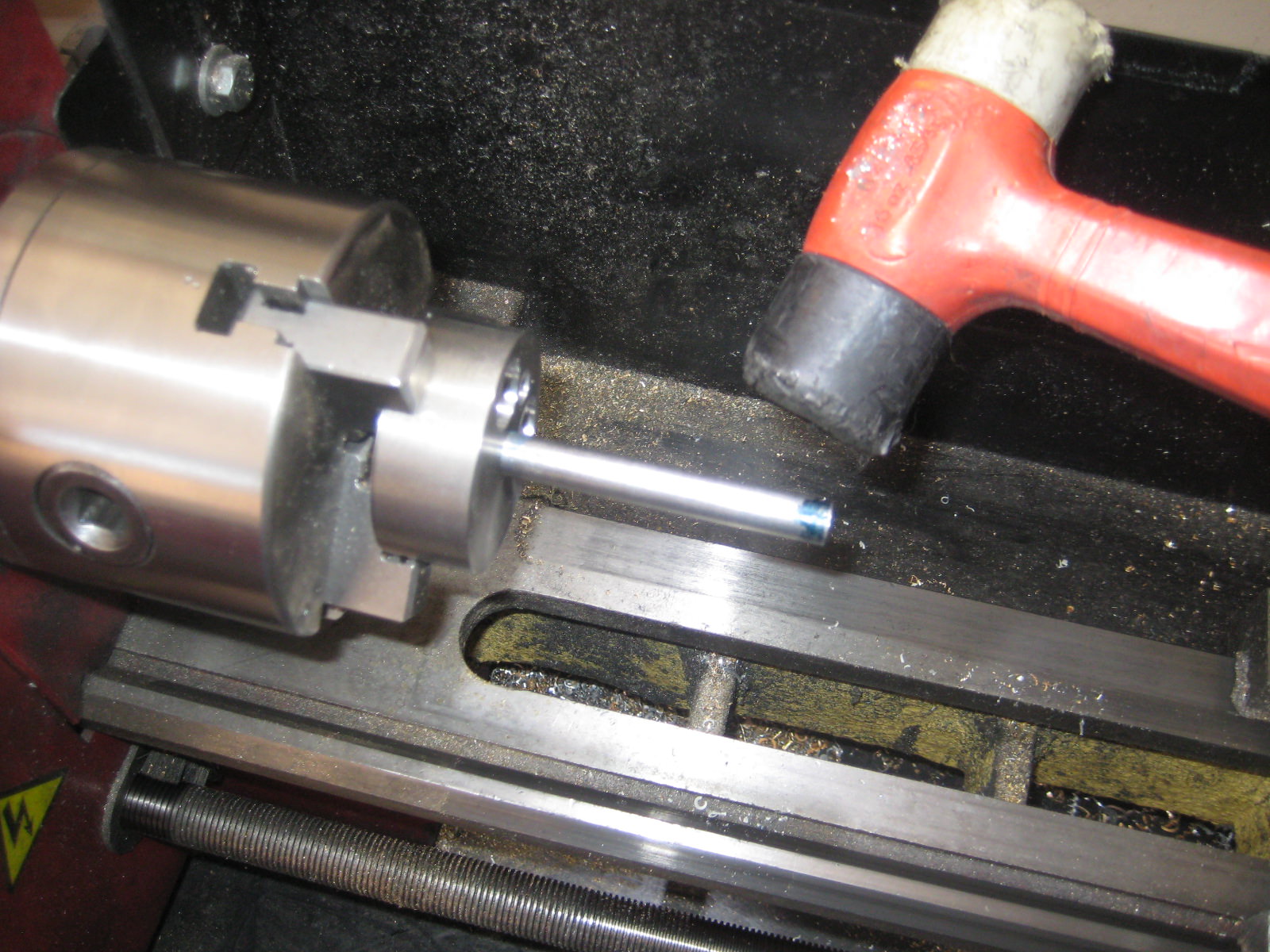

I'm building the SHAN steam engine from Model Engine Builder Issue 32, and I'm having difficulty assembling the parts I've made. I think the problem is that the piston and rod are not really perpendicular, so the rod doesn't fit the gland or the crosshead. According to the plan, the rod simply screws into the piston. I've attached a picture of the pair assembled, and also the relevant plans. My question is, how does one achieve that perpendicularity? Is it simply a matter of being more meticulous, or is there a jig I should make, or what?