You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New guy, an attempt at the elbow engine.

- Thread starter rustyknife

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

- Joined

- Jan 17, 2009

- Messages

- 887

- Reaction score

- 81

Excellent Eric I bet you've got a big grin. ;D

Elbow engines are not an easy engine to build you should be very pleased that for a first engine you've built one a great achievement.

It looks to run very smoothly too.

:bow: :bow: :bow:

:big: :big: :big:

Stew

Elbow engines are not an easy engine to build you should be very pleased that for a first engine you've built one a great achievement.

It looks to run very smoothly too.

:bow: :bow: :bow:

:big: :big: :big:

Stew

She's a spinner, good job

Robert

Robert

rustyknife

Well-Known Member

- Joined

- Mar 5, 2011

- Messages

- 107

- Reaction score

- 1

Thank you for all the kind words. More progress with follow. I'm still not sure as to a flywheel design.....I may just start whittling on it and see what I can come up with.

Well as embarrassed as I am to say, I don't know nearly enough about steam power. So I'm limited to compressed air until I can gain further knowledge, which appears there is probably a vast amount on this site that would be willing to help.

hopeless said:very nice runner. Once the air leaks are sorted are you going to run on steam or air?

Well done :bow:

Pete

Well as embarrassed as I am to say, I don't know nearly enough about steam power. So I'm limited to compressed air until I can gain further knowledge, which appears there is probably a vast amount on this site that would be willing to help.

rustyknife

Well-Known Member

- Joined

- Mar 5, 2011

- Messages

- 107

- Reaction score

- 1

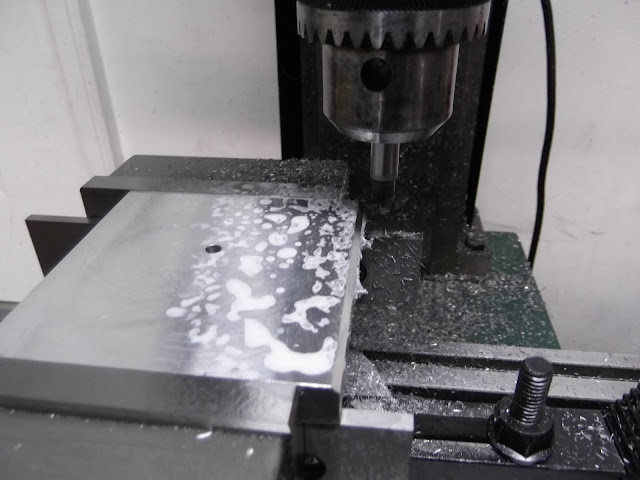

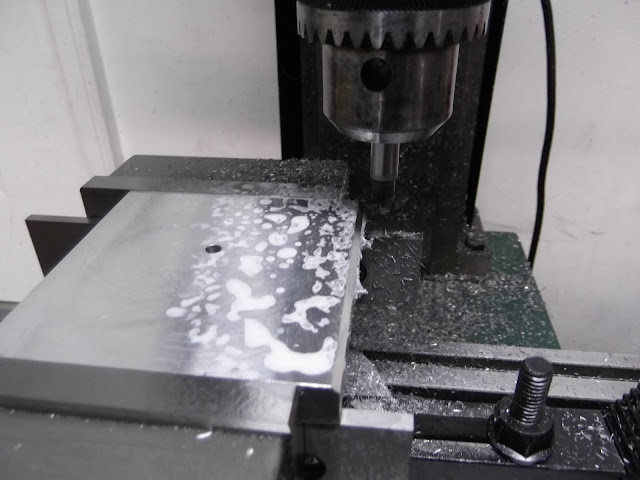

Well today I got a little more progress done. I fitted the flywheel cylinder to the flywheel today...it was quite boring...haha pun intended.

Then flycut to the thickness I desired.

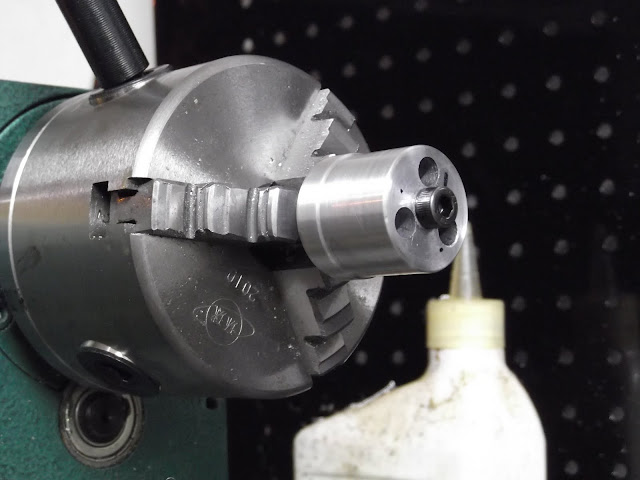

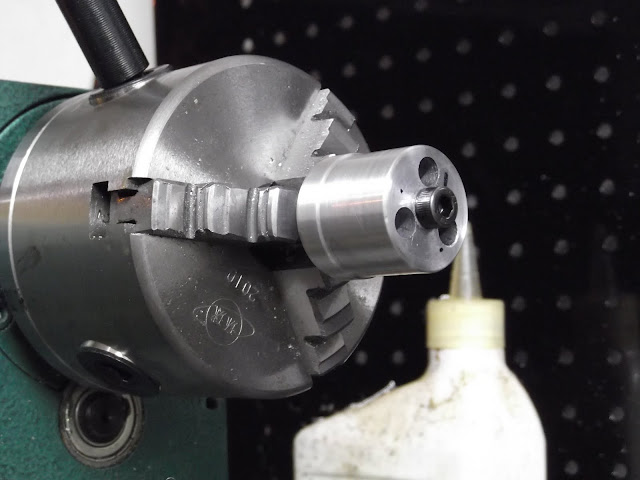

Again ADD kicked in, and I decided to turn up a mandrel for polishing my cylinders.

Assembled the flywheel with sleeve retainer, and left it to sit.

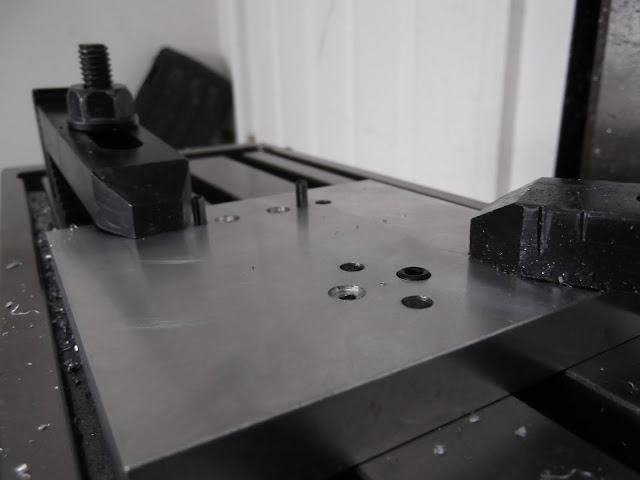

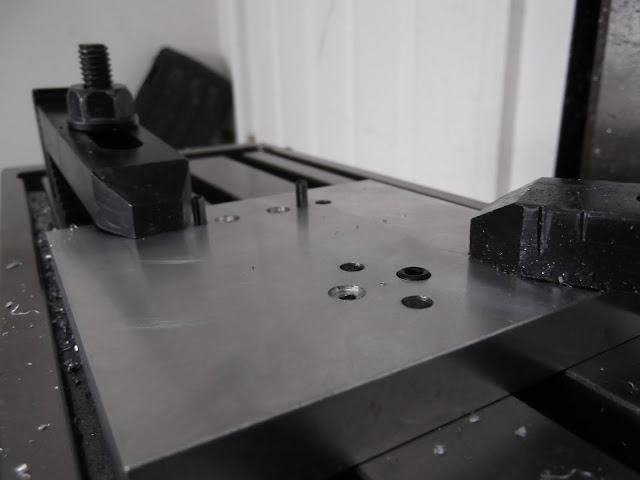

While I let that set up, I decided that I should get more work done the base. Fit for o-rings.

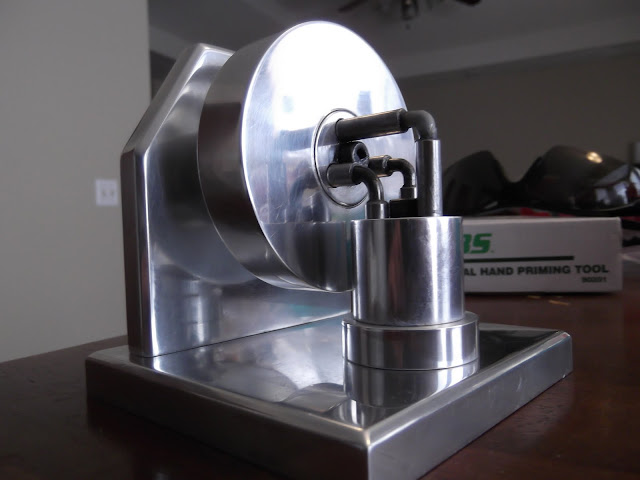

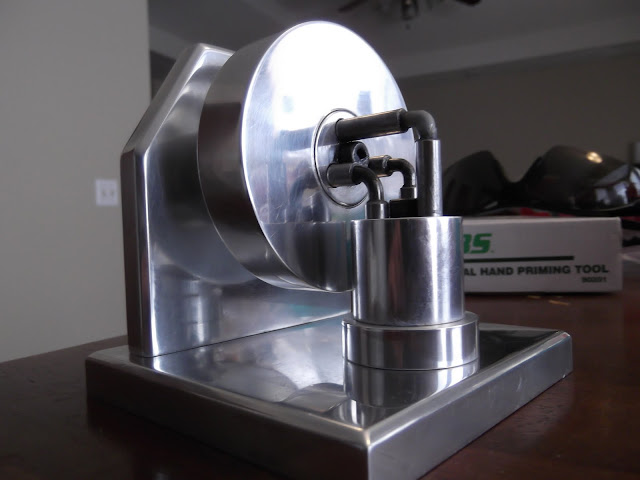

Then, I chamfered the bases edges and I got out the ol' elbow grease (ok I didn't see that pun coming till I typed it) and did some polishing.....the result?

Base is done, and came out awesome.

;D ;D ;D ;D ;D

Then flycut to the thickness I desired.

Again ADD kicked in, and I decided to turn up a mandrel for polishing my cylinders.

Assembled the flywheel with sleeve retainer, and left it to sit.

While I let that set up, I decided that I should get more work done the base. Fit for o-rings.

Then, I chamfered the bases edges and I got out the ol' elbow grease (ok I didn't see that pun coming till I typed it) and did some polishing.....the result?

Base is done, and came out awesome.

;D ;D ;D ;D ;D

rustyknife

Well-Known Member

- Joined

- Mar 5, 2011

- Messages

- 107

- Reaction score

- 1

A few days ago I went ahead and shaped my flywheel post. beveled all the edges and such

The engine is now complete.

I must say.....its pretty incredible how perfect everything must be. I probably spent two hours last night getting it to run again.

I had gotten the cylinder play to the valve ports down to .001" which was not nearly good enough. Polishing the faces where the cylinders and valve ports meet was a HUGE mistake. Massive, air leak....so massive it would not run. I had to to take and sand each one flat on a piece of glass. Then take a file and sand paper to the axle pins to make them just drag against each other......Then the timing was off and it took a little rotation of the flywheel valve port to get it going....But now she is a runner and I'm calling this project completed.

My polishing arsenal consisted of sandpaper starting at 220, then 320 then 600. Followed by Tripoli compound on a laminated sisal wheel, then fine compound on a spiral sewn, then red rouge on a loose muslin. Followed by a hand buff with mothers aluminum wheel polish.

Finished: http://www.homemodelenginemachinist.com/index.php?topic=15698.0

Regards,

Eric

The engine is now complete.

I must say.....its pretty incredible how perfect everything must be. I probably spent two hours last night getting it to run again.

I had gotten the cylinder play to the valve ports down to .001" which was not nearly good enough. Polishing the faces where the cylinders and valve ports meet was a HUGE mistake. Massive, air leak....so massive it would not run. I had to to take and sand each one flat on a piece of glass. Then take a file and sand paper to the axle pins to make them just drag against each other......Then the timing was off and it took a little rotation of the flywheel valve port to get it going....But now she is a runner and I'm calling this project completed.

My polishing arsenal consisted of sandpaper starting at 220, then 320 then 600. Followed by Tripoli compound on a laminated sisal wheel, then fine compound on a spiral sewn, then red rouge on a loose muslin. Followed by a hand buff with mothers aluminum wheel polish.

Finished: http://www.homemodelenginemachinist.com/index.php?topic=15698.0

Regards,

Eric

Similar threads

- Replies

- 13

- Views

- 1K

- Replies

- 111

- Views

- 21K