You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My version of a Goodall boiler top up valve.

- Thread starter Tony Bird

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

KBC

Junior Member

- Joined

- Feb 22, 2012

- Messages

- 80

- Reaction score

- 53

Tony.

It looks like the old style cycle tyre valve where you had a rubber sleeve over the valve.

We used to carry small a tin with puncture repair kit, many a time on a cold day trying to repair a puncture and the rubber valve was perished they were cursed as there wasn't much you could do if no spare was available.

George,

It looks like the old style cycle tyre valve where you had a rubber sleeve over the valve.

We used to carry small a tin with puncture repair kit, many a time on a cold day trying to repair a puncture and the rubber valve was perished they were cursed as there wasn't much you could do if no spare was available.

George,

modeng2000

Well-Known Member

- Joined

- Nov 14, 2008

- Messages

- 146

- Reaction score

- 37

Tony,

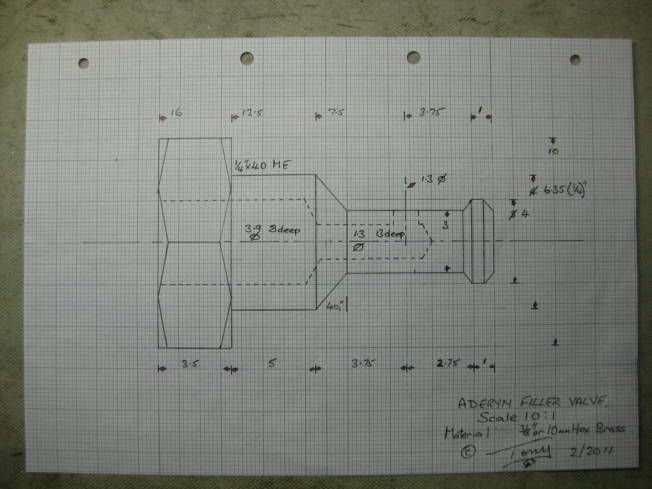

Thanks for the drawing and photos.

It just happens that I need 1/4" by 40!

My main concern was the size of the hole for the water bottle tube.

What did you use for the plastic tube?

John

Thanks for the drawing and photos.

It just happens that I need 1/4" by 40!

My main concern was the size of the hole for the water bottle tube.

What did you use for the plastic tube?

John

Last edited:

Tony Bird

Senior Member

Hi George,

It looks like the old style cycle tyre valve where you had a rubber sleeve over the valve.

We used to carry small a tin with puncture repair kit, many a time on a cold day trying to repair a puncture and the rubber valve was perished they were cursed as there wasn't much you could do if no spare was available.

Quite right, basically a Schrader valve. In the 1980's Deryk Goodall was very successful in getting Mamod Railway Locomotives to work well. Having made them perform he came up with his top-up valve to extend the locomotives running time, this meant that with a top up system for the meths tank the locomotive could be run until boredom set in. The original system for topping up used a syringe both for the meths and water. For the water the plastic end of the syringe was placed directly into the valve. For meths the syringe had a piece of silicon tube on its end which was pushed over a tube that went into the meths tank. The design of the tank was such that the syringe could also remove meths from the tank. Deryk is a diabetic so maybe that is where the idea of using syringes came from, later he came up with the idea of using a garden spray to fill the boiler the syringe was still used for the meths. During the syringe era I had access to ethanol which was clear and didn't smell as much as meths when it burnt. One day the inevitable happened meths was put in the boiler! The locomotive travelled a couple of feet before its exhaust ignited and flames came out of the cylinder along its piston rod, a few feet further and the heat melted the soft soldered cylinders which fell off! From then on the ethanol was dyed with a little meths. Gas isn't as much fun?

Hi John,

Thanks for the drawing and photos. It just happens that I need 1/4" by 40! My main concern was the size of the hole for the water bottle tube. What did you use for the plastic tube?

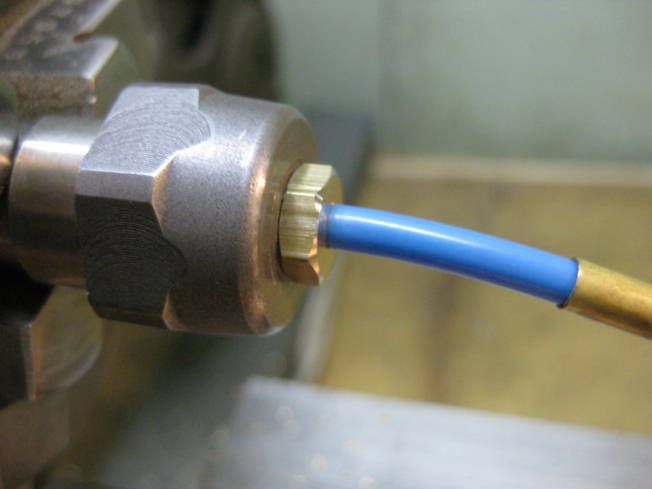

You are welcome. If you are in the UK my water bottle is HoZelock which I bought in B&Q for I think £1.50. The screw spray end needs to be altered to take a 4mm nylon tube, if you have a spare spray you could perhaps use the suction tube from inside the bottle. The size of the tube is not critical but the hole in the valve is, it needs to be 0.10/0.20mm smaller than the tube. The valve tube has to be silicon to stand the heat which I got from a model shop, I think is might be used as fuel line for I.C. engines. Last time I tried to get some the model shop had stopped stocking the smaller sizes but someone told me that it is available in fishing tackle shops, what it might be used for I don't know. I still have about 6" of silicon tube which is good for about 40 valves.

Regards Tony.

It looks like the old style cycle tyre valve where you had a rubber sleeve over the valve.

We used to carry small a tin with puncture repair kit, many a time on a cold day trying to repair a puncture and the rubber valve was perished they were cursed as there wasn't much you could do if no spare was available.

Quite right, basically a Schrader valve. In the 1980's Deryk Goodall was very successful in getting Mamod Railway Locomotives to work well. Having made them perform he came up with his top-up valve to extend the locomotives running time, this meant that with a top up system for the meths tank the locomotive could be run until boredom set in. The original system for topping up used a syringe both for the meths and water. For the water the plastic end of the syringe was placed directly into the valve. For meths the syringe had a piece of silicon tube on its end which was pushed over a tube that went into the meths tank. The design of the tank was such that the syringe could also remove meths from the tank. Deryk is a diabetic so maybe that is where the idea of using syringes came from, later he came up with the idea of using a garden spray to fill the boiler the syringe was still used for the meths. During the syringe era I had access to ethanol which was clear and didn't smell as much as meths when it burnt. One day the inevitable happened meths was put in the boiler! The locomotive travelled a couple of feet before its exhaust ignited and flames came out of the cylinder along its piston rod, a few feet further and the heat melted the soft soldered cylinders which fell off! From then on the ethanol was dyed with a little meths. Gas isn't as much fun?

Hi John,

Thanks for the drawing and photos. It just happens that I need 1/4" by 40! My main concern was the size of the hole for the water bottle tube. What did you use for the plastic tube?

You are welcome. If you are in the UK my water bottle is HoZelock which I bought in B&Q for I think £1.50. The screw spray end needs to be altered to take a 4mm nylon tube, if you have a spare spray you could perhaps use the suction tube from inside the bottle. The size of the tube is not critical but the hole in the valve is, it needs to be 0.10/0.20mm smaller than the tube. The valve tube has to be silicon to stand the heat which I got from a model shop, I think is might be used as fuel line for I.C. engines. Last time I tried to get some the model shop had stopped stocking the smaller sizes but someone told me that it is available in fishing tackle shops, what it might be used for I don't know. I still have about 6" of silicon tube which is good for about 40 valves.

Regards Tony.

Last edited:

Tony Bird

Senior Member

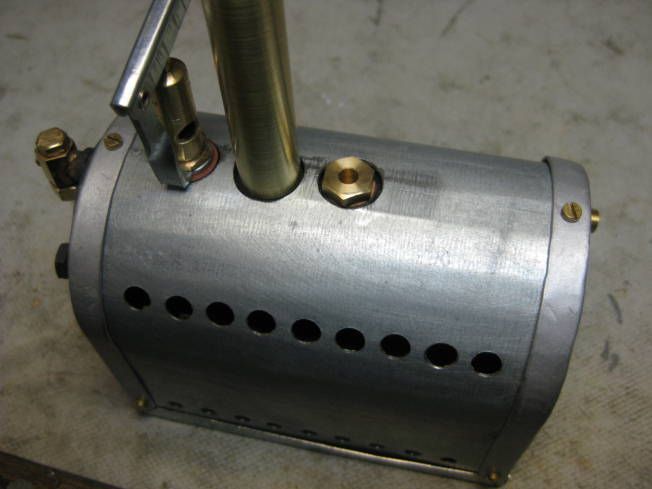

Hi,

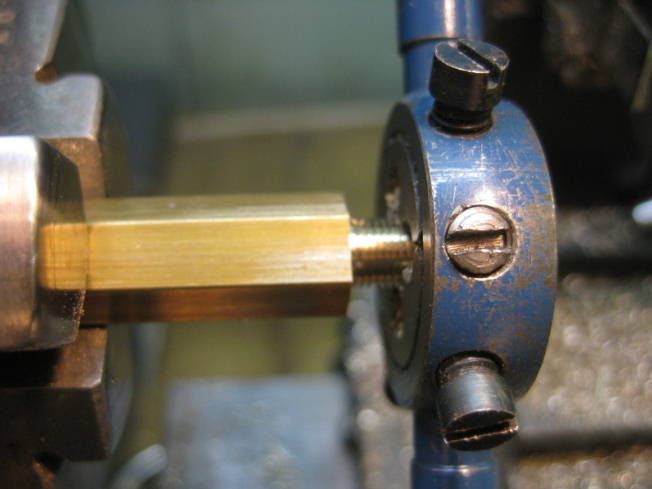

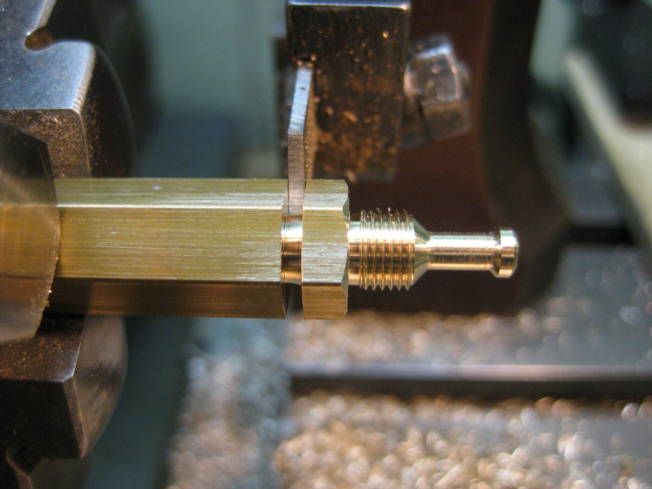

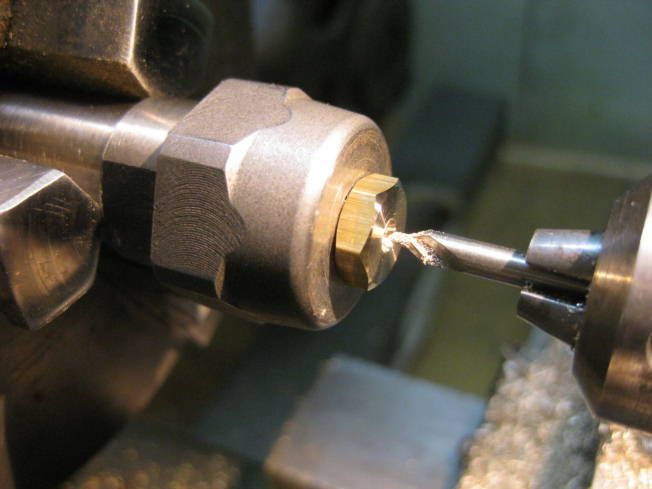

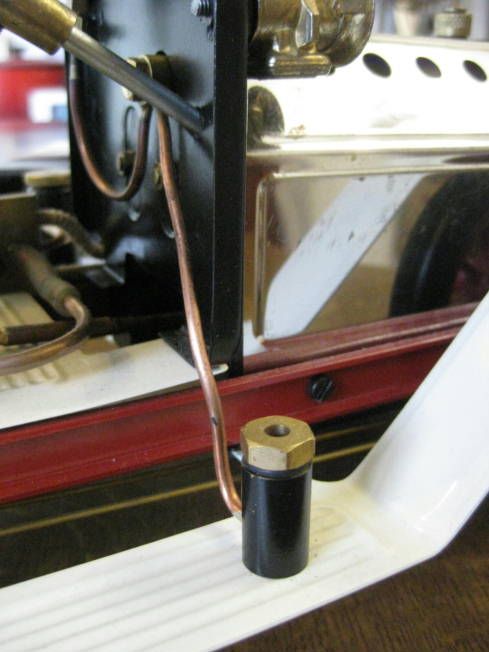

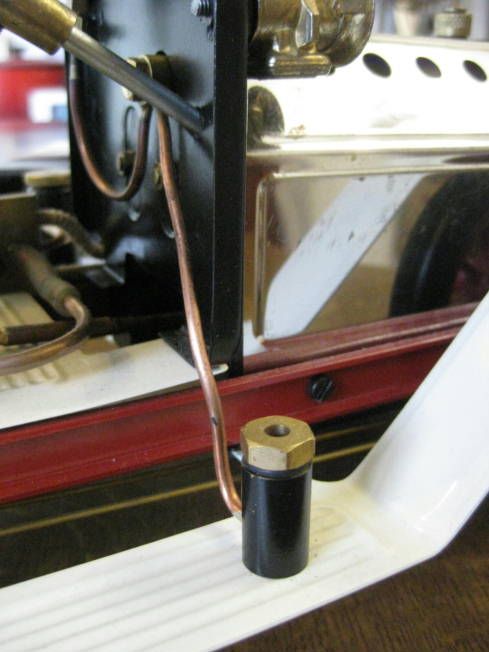

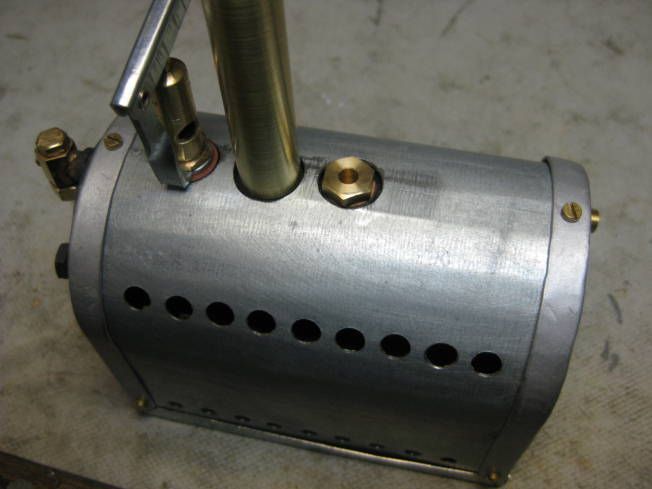

Before going off to the big city to see a matinee this afternoon I put a recently made gas tank on its low pressure test and I thought some photographs will be found interesting. The hand pump can easily manage 200psi the handle breaks at around 220psi. The K&S brass tube around the nylon pipe is to make it rigid while it is put in the valve.

My pressure test gauge uses a Goodall valve as a none return valve after the Enots pipe connector and easily stands the 350psi pressure it is frequently subjected to. Did you know that Enots is Stone spelt backwards? The inventor?

Modifications to the HoZelock spray bottle.

Other ways of using Goodall valves.

The 1/4" BSF valve fitted and another to make.

Hope this is found interesting.

Regards Tony.

Before going off to the big city to see a matinee this afternoon I put a recently made gas tank on its low pressure test and I thought some photographs will be found interesting. The hand pump can easily manage 200psi the handle breaks at around 220psi. The K&S brass tube around the nylon pipe is to make it rigid while it is put in the valve.

My pressure test gauge uses a Goodall valve as a none return valve after the Enots pipe connector and easily stands the 350psi pressure it is frequently subjected to. Did you know that Enots is Stone spelt backwards? The inventor?

Modifications to the HoZelock spray bottle.

Other ways of using Goodall valves.

The 1/4" BSF valve fitted and another to make.

Hope this is found interesting.

Regards Tony.

RonGinger

Well-Known Member

Thank you for that photo of the spray bottle fitting. I have been wondering how a tight joint was made to a plastic spray nozzle.

All of your photos and description have been very useful, thanks for posting them.

All of your photos and description have been very useful, thanks for posting them.

modeng2000

Well-Known Member

- Joined

- Nov 14, 2008

- Messages

- 146

- Reaction score

- 37

Here is my Goodall valve I made this morning.

Thanks again Tony. I did my best to search the net for valve dimensions but didn't find anything. Have filed away your drawing for future use.

The next thing to do is pressure test the boiler.

John

Last edited:

Tony Bird

Senior Member

Hi John,

Excellent job! You could use it to pressure test your boiler. You might find that you will need less effort to operate the valve if the silicon tube isn't such a good fit length wise on the valve that's why the ends of the slot are angled. Square ended slots do work, a lot of the commercially made valves use them but I found that the angled ends seem to need less effort to operate especially at higher pressures. As I use the valves for testing both boilers and gas tanks it might be more relevant for me.

Regards Tony.

Excellent job! You could use it to pressure test your boiler. You might find that you will need less effort to operate the valve if the silicon tube isn't such a good fit length wise on the valve that's why the ends of the slot are angled. Square ended slots do work, a lot of the commercially made valves use them but I found that the angled ends seem to need less effort to operate especially at higher pressures. As I use the valves for testing both boilers and gas tanks it might be more relevant for me.

Regards Tony.

modeng2000

Well-Known Member

- Joined

- Nov 14, 2008

- Messages

- 146

- Reaction score

- 37

Tony,

I hadn't considered the length of the tube and why you angled the ends of the tube recess.

Out of interest the tube I used came from a fishing tackle shop where it is sold to be cut into rings to be used to attach floats to fishing line!!!

I shall have a gas tank to test when more of the loco is finished.

Regards,

John

I hadn't considered the length of the tube and why you angled the ends of the tube recess.

Out of interest the tube I used came from a fishing tackle shop where it is sold to be cut into rings to be used to attach floats to fishing line!!!

I shall have a gas tank to test when more of the loco is finished.

Regards,

John

charlesfitton

Well-Known Member

- Joined

- Jan 10, 2010

- Messages

- 163

- Reaction score

- 24

now that is slick!

Tony Bird

Senior Member

Hi John,

I hadn't considered the length of the tube and why you angled the ends of the tube recess.

The one that you have made should work OK but I would shorten the silicon tube a bit

Out of interest the tube I used came from a fishing tackle shop where it is sold to be cut into rings to be used to attach floats to fishing line!!!

Well I now know what to ask for when I need some.

I shall have a gas tank to test when more of the loco is finished.

The valve is certainly up to the job of testing a gas tank which for a 70/30 butane/propane mix the suggested test pressure is 330psi in the UK. I usually use the spray bottle take the initial pressure up to around 200psi the tube is removed from the Enots fitting and after about half an hour a conventional hand pump is connected and used to take the pressure higher.

Regards Tony.

I hadn't considered the length of the tube and why you angled the ends of the tube recess.

The one that you have made should work OK but I would shorten the silicon tube a bit

Out of interest the tube I used came from a fishing tackle shop where it is sold to be cut into rings to be used to attach floats to fishing line!!!

Well I now know what to ask for when I need some.

I shall have a gas tank to test when more of the loco is finished.

The valve is certainly up to the job of testing a gas tank which for a 70/30 butane/propane mix the suggested test pressure is 330psi in the UK. I usually use the spray bottle take the initial pressure up to around 200psi the tube is removed from the Enots fitting and after about half an hour a conventional hand pump is connected and used to take the pressure higher.

Regards Tony.

modeng2000

Well-Known Member

- Joined

- Nov 14, 2008

- Messages

- 146

- Reaction score

- 37

Tony,

This is what I have been up to recently. I followed your design pretty much and have ended up with something that will be very useful. I would have liked a longer nut on the gauge connection but I think it will be satisfactory.

I still have to make the Ronson adapter, (M5?) to 1/4" x 40 which is the common thread I have used on one end of the adapter.

Now perhaps I'll be able to find time to test the boiler and find if my silver soldering is good enough!!!

John

Tony Bird

Senior Member

modeng2000

Well-Known Member

- Joined

- Nov 14, 2008

- Messages

- 146

- Reaction score

- 37

Hi Tony,

I can now see the problems that might be met on a finished model.

Isn't it a pity that Ronson didn't use a more common thread! Some more tooling to get.

Regards,

John

I can now see the problems that might be met on a finished model.

Isn't it a pity that Ronson didn't use a more common thread! Some more tooling to get.

Regards,

John

Similar threads

- Replies

- 57

- Views

- 9K

- Replies

- 26

- Views

- 8K