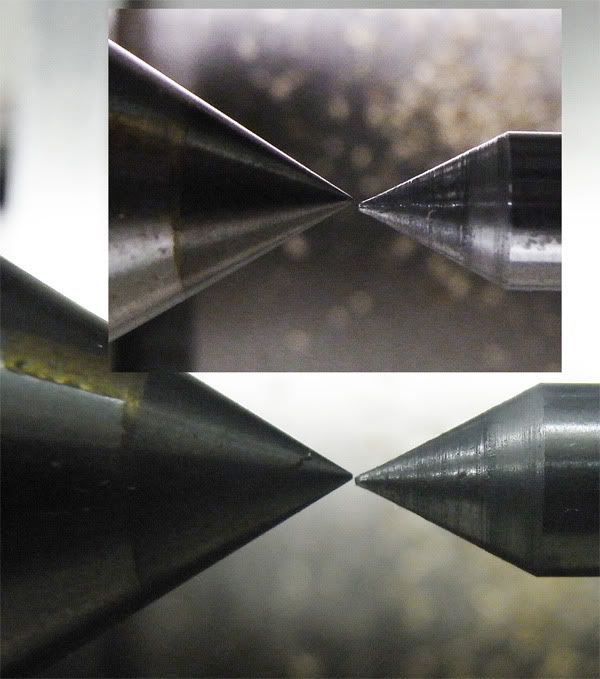

I noticed last night when drilling my tailstock was slightly out of alignment and checking it today is seams to be out of alignment but atleast 1mm.

I'm going to try and adjust the tailstock tonight but I have no idea how it has got out of alignment.

I have checked the ways and the underside of the tailstock and they are all ok and free of chips.

I'm confused as to what has happened as nothing seems loose anywhere to allow that much movement.

I'm going to try and adjust the tailstock tonight but I have no idea how it has got out of alignment.

I have checked the ways and the underside of the tailstock and they are all ok and free of chips.

I'm confused as to what has happened as nothing seems loose anywhere to allow that much movement.