I have been working on these engines for a while. I didn't keep track of the time involved, but for me it was a slow process.

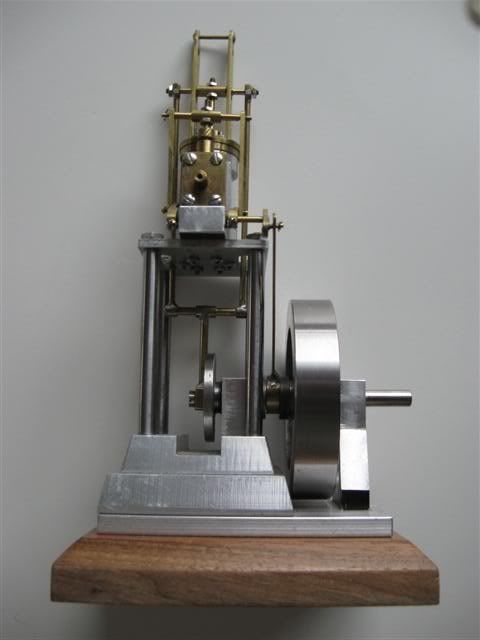

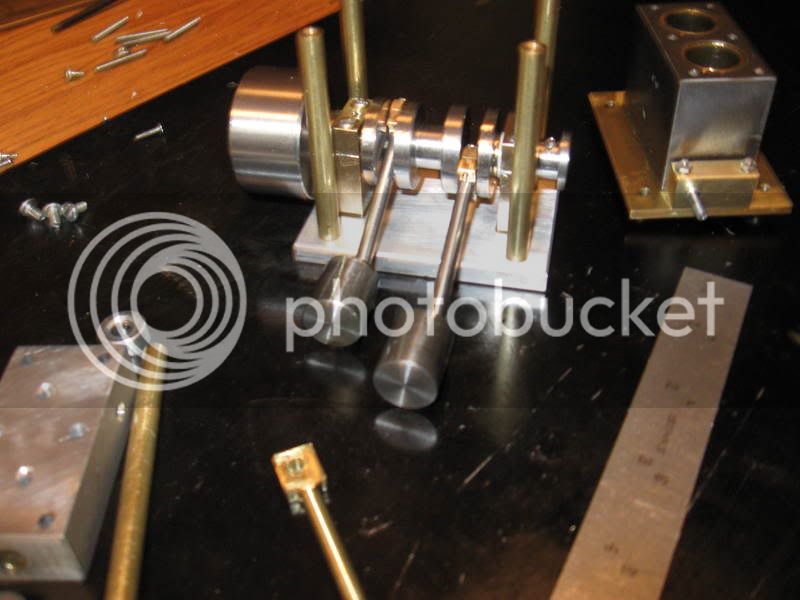

The completed single cylinder one runs real nice on just 4 PSI. I am happy with the results so far.

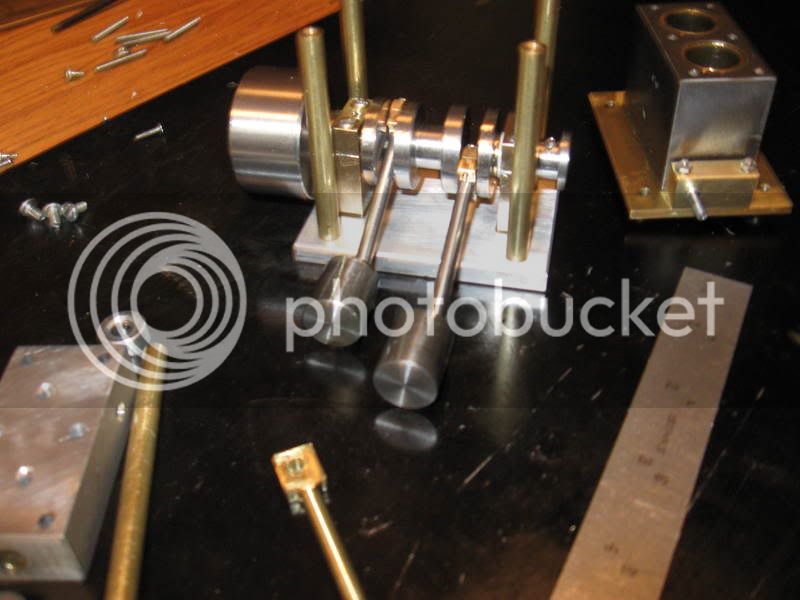

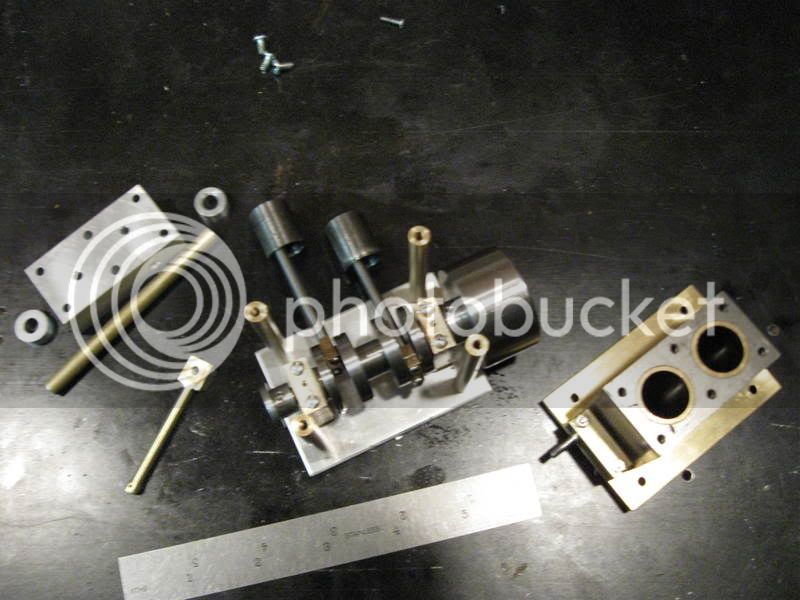

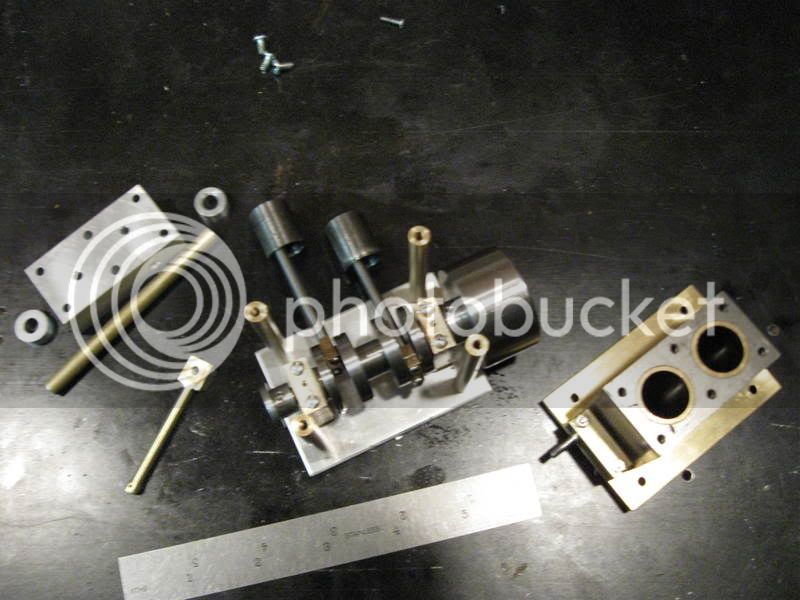

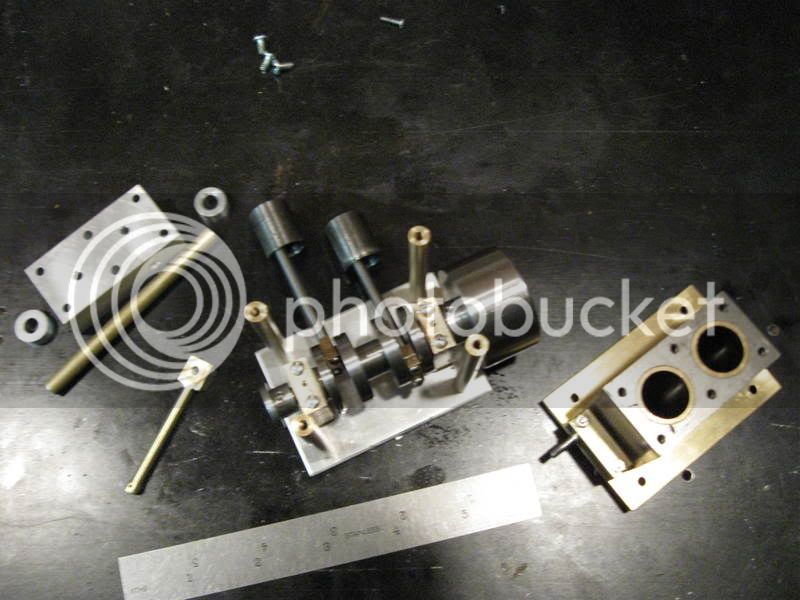

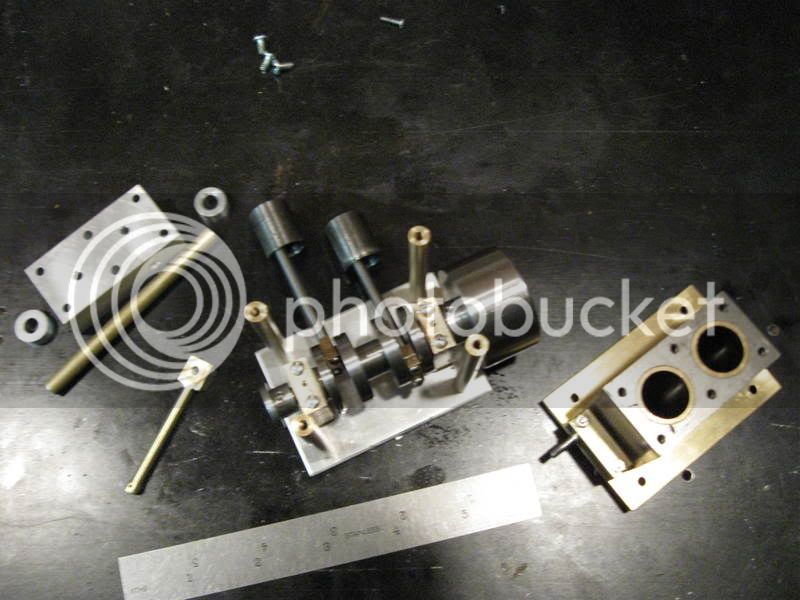

The one shown in different stages of completion is a two cylinder that I found on the internet. I think it is from an old Poplar Mechanics magazine. This engine is now running. It needs more run in time but goes pretty good as is. I think I will try to make a new crankshaft when it gets a lot warmer in the garage.

Thanks for looking. Hope the pictures will inspire others to tackle one of these.

The completed single cylinder one runs real nice on just 4 PSI. I am happy with the results so far.

The one shown in different stages of completion is a two cylinder that I found on the internet. I think it is from an old Poplar Mechanics magazine. This engine is now running. It needs more run in time but goes pretty good as is. I think I will try to make a new crankshaft when it gets a lot warmer in the garage.

Thanks for looking. Hope the pictures will inspire others to tackle one of these.