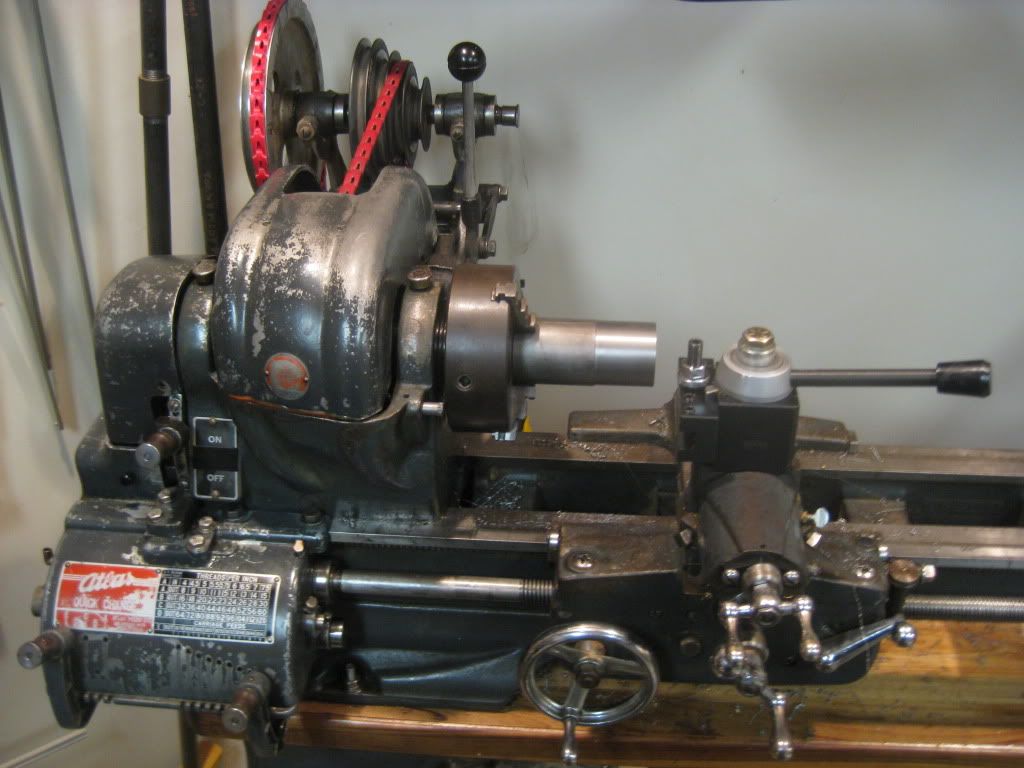

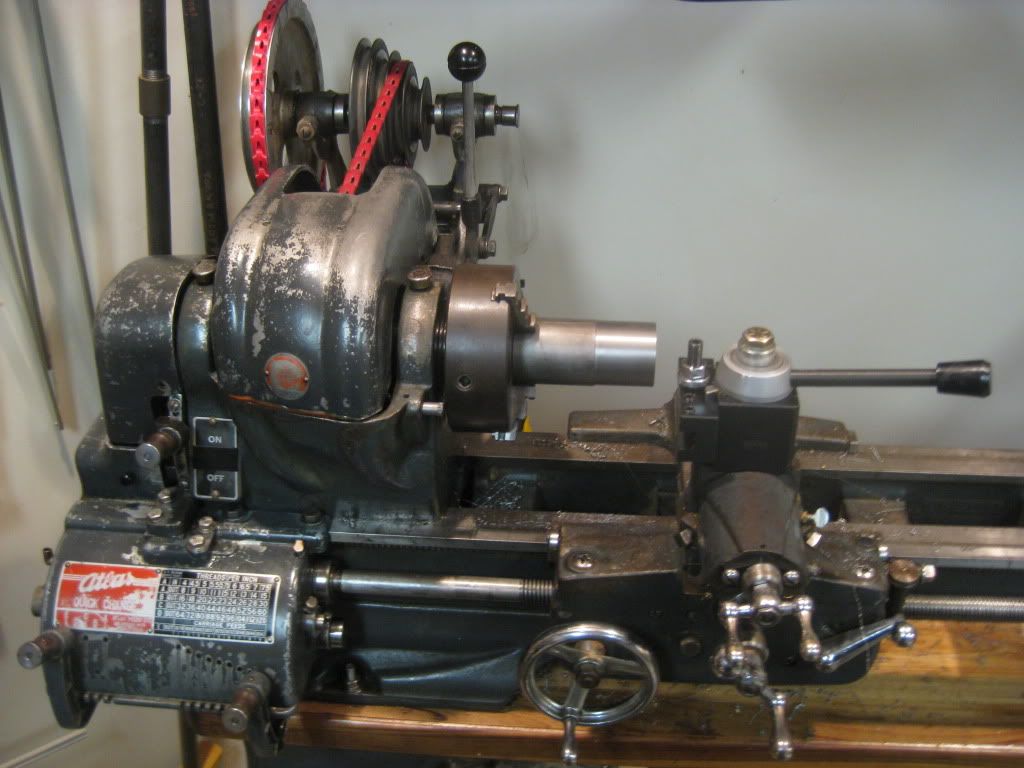

By way of introduction, I am a tax lawyer, and have done a lot of woodworking. I was given an Atlas 10F54, which I spent some time (and many dollars) fixing up, as it was in pretty bad shape, with busted gears in the QCGB, as well as on the spindle, a broken large pulley on the countershaft, and an inch thick coating of gunk. I used it for a number of years in making 5 string banjos (turning the rims and shaping the rim / neck joint) and doing some metalworking for basic maintenance and repair on home projects, and maintaining my old John Deere garden tractor.

Lately, I decided to get into model engineering, and joined this site. I also have a Sherline lathe, which I have used for some basic metalworking, mostly in connection with my wood working. I am pretty much a novice, tho my dad was a tool and die maker (that is his tool box under the lathe in the picture below), and I worked in his shop for a summer when my truck driving job was shut down by a strike.

here is a picture or two of my lathe:

Obviously, I didn't clean up before taking the shots! Could use a paint job, I guess, but with the amount of oil on it, I'm not worried about rust.

The piece in the chuck is a 2 inch diameter piece of 1018. I was having a heck of a time getting a decent finish on it. I did a lot of reading on this site, and decided I needed to learn to grind HSS tool bits, so I bought this grinder from Harbor freight. With 20% off, it was about $125. Not a Cadillac by any means, but it does the job.

So, I was able to sharpen my el cheapo chinese brazed carbide bits, which was great for roughing cuts, and then ground a HSS shearing bit, based on the threads on this site, to get a finish cut. My photography isn't great, but I was pretty happy for with the finish, for an old Atlas and one of my first hand ground bits:

Next time I will smooth the bit with a fine stone, and use some cutting oil, to see if I can get a smoother finish. It looks pretty good at normal magnification, but under my magnifying lamp, it still looks like a very fine thread on the part.

I have recently started building n ML-17 compression ignition engine from bar stock, and am also interested in making a Webster. I am not going to do a build thread until I get a little confidence that I can do work worthy of a build thread.

Thanks for listening, and please feel free to make any suggestions or comments that occur to you. I have learned a great deal on this site, and I respect the qualifications of so many of you, and your willingness to share your knowledge. And i have a pretty thick skin!

Lately, I decided to get into model engineering, and joined this site. I also have a Sherline lathe, which I have used for some basic metalworking, mostly in connection with my wood working. I am pretty much a novice, tho my dad was a tool and die maker (that is his tool box under the lathe in the picture below), and I worked in his shop for a summer when my truck driving job was shut down by a strike.

here is a picture or two of my lathe:

Obviously, I didn't clean up before taking the shots! Could use a paint job, I guess, but with the amount of oil on it, I'm not worried about rust.

The piece in the chuck is a 2 inch diameter piece of 1018. I was having a heck of a time getting a decent finish on it. I did a lot of reading on this site, and decided I needed to learn to grind HSS tool bits, so I bought this grinder from Harbor freight. With 20% off, it was about $125. Not a Cadillac by any means, but it does the job.

So, I was able to sharpen my el cheapo chinese brazed carbide bits, which was great for roughing cuts, and then ground a HSS shearing bit, based on the threads on this site, to get a finish cut. My photography isn't great, but I was pretty happy for with the finish, for an old Atlas and one of my first hand ground bits:

Next time I will smooth the bit with a fine stone, and use some cutting oil, to see if I can get a smoother finish. It looks pretty good at normal magnification, but under my magnifying lamp, it still looks like a very fine thread on the part.

I have recently started building n ML-17 compression ignition engine from bar stock, and am also interested in making a Webster. I am not going to do a build thread until I get a little confidence that I can do work worthy of a build thread.

Thanks for listening, and please feel free to make any suggestions or comments that occur to you. I have learned a great deal on this site, and I respect the qualifications of so many of you, and your willingness to share your knowledge. And i have a pretty thick skin!