I love a good deal when it comes around and I think I got one here. A few weeks ago I put out word that I wanted a lathe and a buddy of mine said his dad had one in the barn and was tired of moving it around. That Friday I went to pick it up, hard to pass up for free.

Anyway, here are a few pics

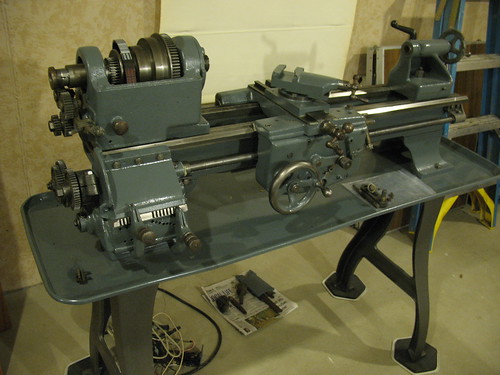

Here it is where I picked it up.

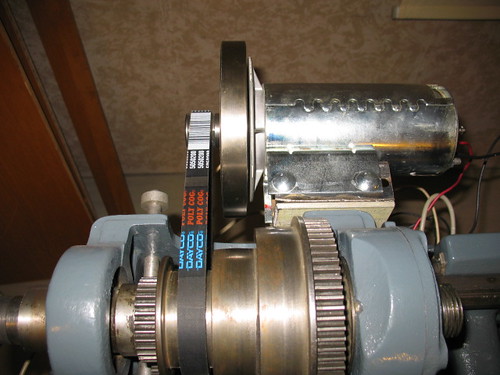

Two days later

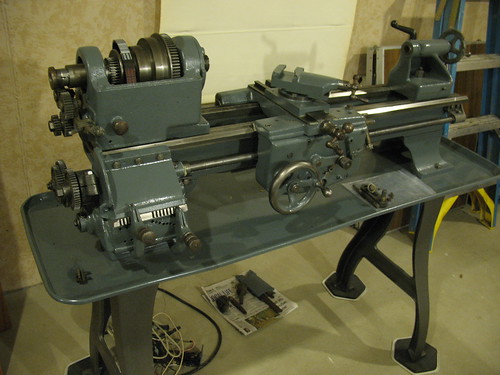

A week later

This weekend

Anyway, here are a few pics

Here it is where I picked it up.

Two days later

A week later

This weekend