Oldmechthings

Well-Known Member

- Joined

- Jan 10, 2008

- Messages

- 153

- Reaction score

- 12

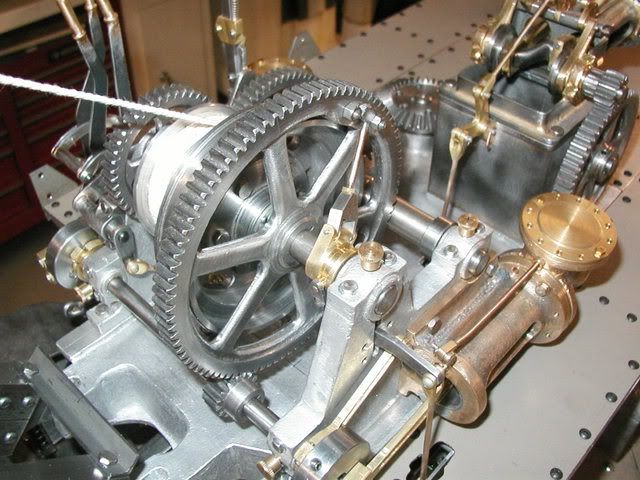

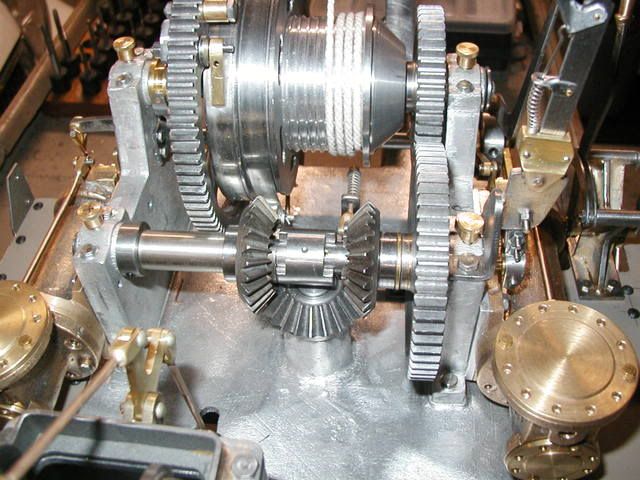

I better bring you up to date on the model steam shovel. As of today I have the bucket complete and operational. I put lots of rivets in it. Hopefully the same number as in the original. Oh!, and it has teeth too. It is always exciting when babies get teeth.

That almost finishes the "shovel" end of the machine, Now I need to move back towards the rear and work on the "Steaming" end.

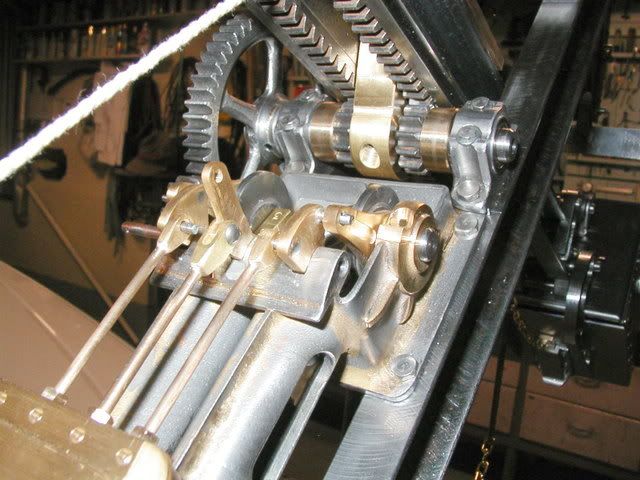

Rivets really set a model off, and I install a lot of them. There are dozens in that bucket alone. Rarely do I ever set one with a hammer. I always use a rivet press. It is so much faster, and easier, and I end up with a nice looking head on both ends. Shown below is my assortment of rivet presses.

The red one is a commercially built one that my dad once used on the farm on his mowing machines. It will easily squeeze a 3/16" rivet. The gray one is one that I made out of 3/4" plate steel to install 1/8" rivets in the frame of a model steam roller, and I also used it to rivet the frame for the Steam Shovel shown above. The tiny little press was used to install hundreds of rivets in that Hay Press and a model Manure Spreader. For those rivets, snipped off 19 gage wire brads were used. They are about .035" diameter. They have heads that look like finishing nails, until after they are pressed and then they look like rivet heads. The press with the deep throat was made just last Friday, specifically to rivet the bucket together. For that I used 3/32" rivets.

All the presses have cups in the anvil and screw the shape of the head. If it is desired to change the shape of the head, just change the shape of the cup. For screws I use square head set screws or socket head screws because they are a little harder than a regular bolt. The last two presses I used a piece of tool steel for the anvil. That makes changing the shape very simple.

If pressing rivets seems a little strange, dig out your century old history books and see how they did it. Yes, they used jack hammers sometimes, but where ever it was feasible they used a press, big ones!

Birk

That almost finishes the "shovel" end of the machine, Now I need to move back towards the rear and work on the "Steaming" end.

Rivets really set a model off, and I install a lot of them. There are dozens in that bucket alone. Rarely do I ever set one with a hammer. I always use a rivet press. It is so much faster, and easier, and I end up with a nice looking head on both ends. Shown below is my assortment of rivet presses.

The red one is a commercially built one that my dad once used on the farm on his mowing machines. It will easily squeeze a 3/16" rivet. The gray one is one that I made out of 3/4" plate steel to install 1/8" rivets in the frame of a model steam roller, and I also used it to rivet the frame for the Steam Shovel shown above. The tiny little press was used to install hundreds of rivets in that Hay Press and a model Manure Spreader. For those rivets, snipped off 19 gage wire brads were used. They are about .035" diameter. They have heads that look like finishing nails, until after they are pressed and then they look like rivet heads. The press with the deep throat was made just last Friday, specifically to rivet the bucket together. For that I used 3/32" rivets.

All the presses have cups in the anvil and screw the shape of the head. If it is desired to change the shape of the head, just change the shape of the cup. For screws I use square head set screws or socket head screws because they are a little harder than a regular bolt. The last two presses I used a piece of tool steel for the anvil. That makes changing the shape very simple.

If pressing rivets seems a little strange, dig out your century old history books and see how they did it. Yes, they used jack hammers sometimes, but where ever it was feasible they used a press, big ones!

Birk