BobWarfield

Well-Known Member

- Joined

- Dec 27, 2007

- Messages

- 1,151

- Reaction score

- 1

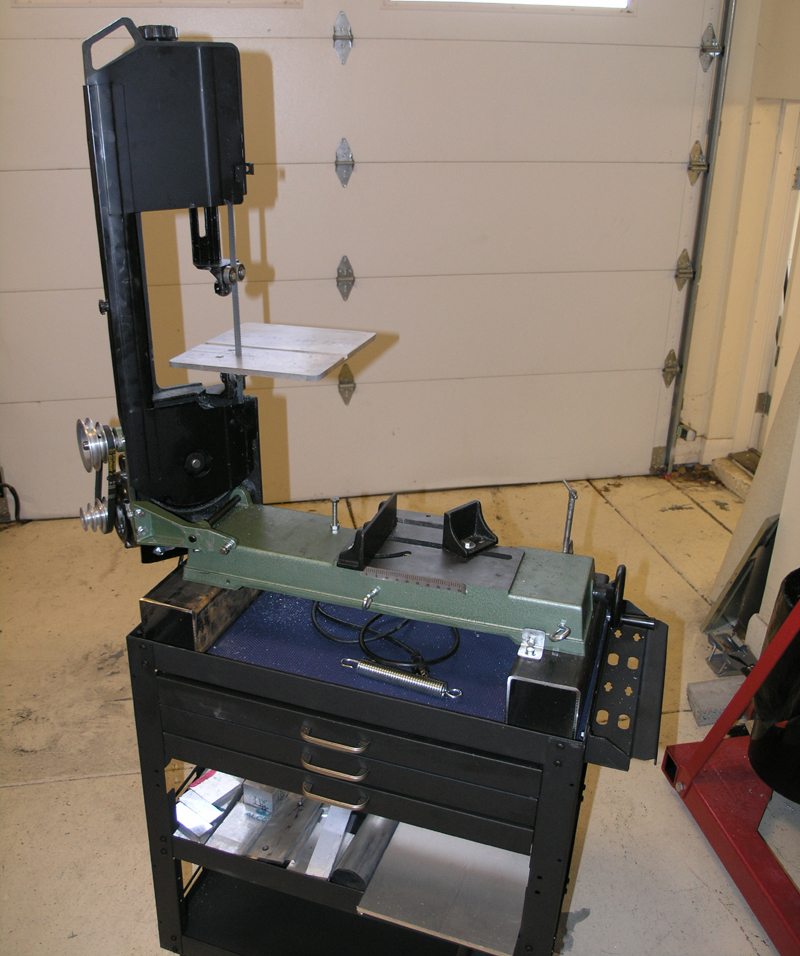

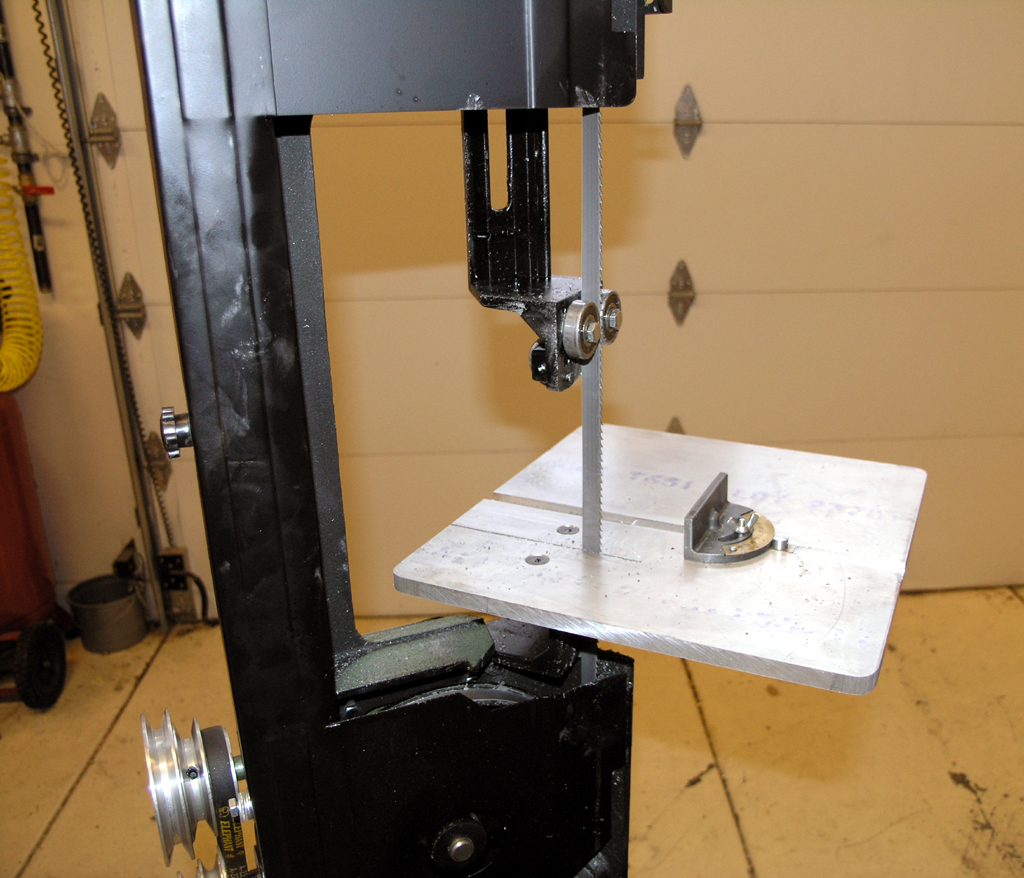

It was a good day in the shop today as I futzed with several odds and ends. The most important of which was a long standing project involing my mini-bandsaw. I wanted to mount it on a rolling cart that is sturdier and add a nice table to it. I had all but quit using it entirely for cut off work since purchasing my DeWalt Multicutter 2 1/2 years ago. I figured that adding the table and getting it out where it would be more accessible will mean I use it more.

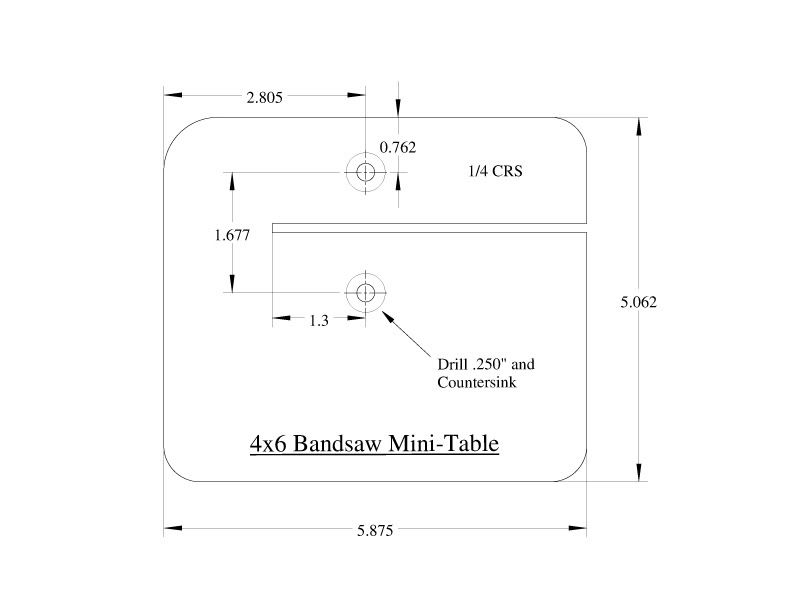

The table was easy:

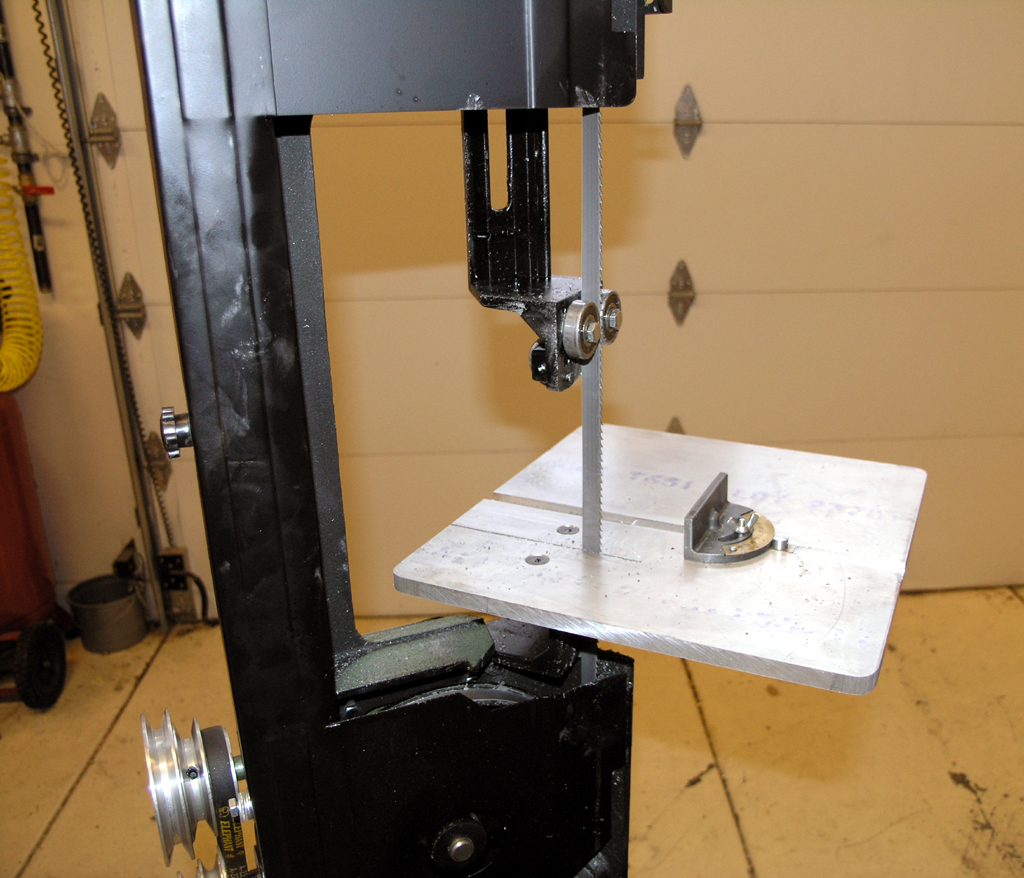

I've already used it once to help make some cuts on a little workpiece that would've been impossible on the bigger chop saw.

A little more info available on my web site here: http://www.cnccookbook.com/CCMiniBandsaw.htm

I made the tooling slot to match my HF Tool Grinder and 12" Disc Sander so I can exchange tooling such as this little mitre gage:

The other thing I did today was to try out my new Drill Doctor. They'd been on sale for $99 on Amazon for the DD750. It worked out great. Took me 10 minutes from start to finish to split point a 3/8" bit that was pretty dull. It cut way better after that. The DD is somewhat complex to use (lots of steps), but really not that hard if you follow the directions. I consider it to have been a good buy considering what new bits cost.

Cheers,

BW

The table was easy:

I've already used it once to help make some cuts on a little workpiece that would've been impossible on the bigger chop saw.

A little more info available on my web site here: http://www.cnccookbook.com/CCMiniBandsaw.htm

I made the tooling slot to match my HF Tool Grinder and 12" Disc Sander so I can exchange tooling such as this little mitre gage:

The other thing I did today was to try out my new Drill Doctor. They'd been on sale for $99 on Amazon for the DD750. It worked out great. Took me 10 minutes from start to finish to split point a 3/8" bit that was pretty dull. It cut way better after that. The DD is somewhat complex to use (lots of steps), but really not that hard if you follow the directions. I consider it to have been a good buy considering what new bits cost.

Cheers,

BW