As many of you know, I am always looking for some novel piece of equipment I can build to run with my model engines. Nothing overly elaborate, but not something as simple as a Ferris wheel. It has to be something with good visuals. Whatever it is has to be visible as working within a three minute window, as that is about the limit of time people will devote to an on-line video. Last night as I was trying to go to sleep, I thought about a machine that blows up a balloon. Great visuals, color of my choice, and fun. It would have to be a piston style compressor with a fairly large displacement. (To fit into the 3 minute time window.) I'll have to think on that one a bit.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Model Compressor---Maybe

- Thread starter Brian Rupnow

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

vederstein

Must do dumb things....

- Joined

- Feb 26, 2011

- Messages

- 917

- Reaction score

- 744

Well last summer I created this for the Maker Faire season. It's not a metal project, but it was run by a steam engine. There was considerable interest in it during the faires. (Probably because it was so weird):

[ame]http://www.youtube.com/watch?v=kxABa1CiMpQ[/ame]

[ame]http://www.youtube.com/watch?v=kxABa1CiMpQ[/ame]

Very cool Vederstein.---Brian

JCSteam

Well-Known Member

- Joined

- Nov 30, 2016

- Messages

- 472

- Reaction score

- 130

I assume you will have seen the slinky see saw? This is a step further and could be a challenge in getting the engine to power it at the correct speed to allow it go down the steps at the correct speed.

https://youtu.be/9dinVcBEDhQ

https://youtu.be/9dinVcBEDhQ

That makes my old "slinky machine" look pretty "lo-tech",

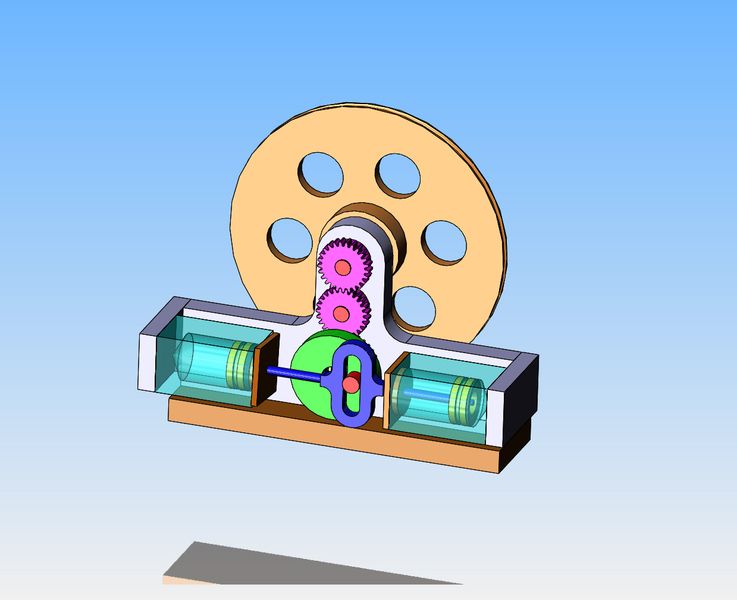

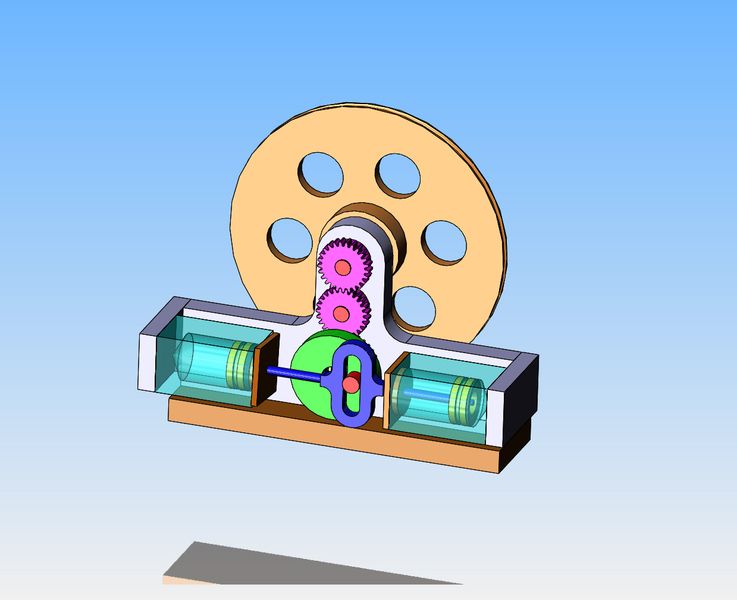

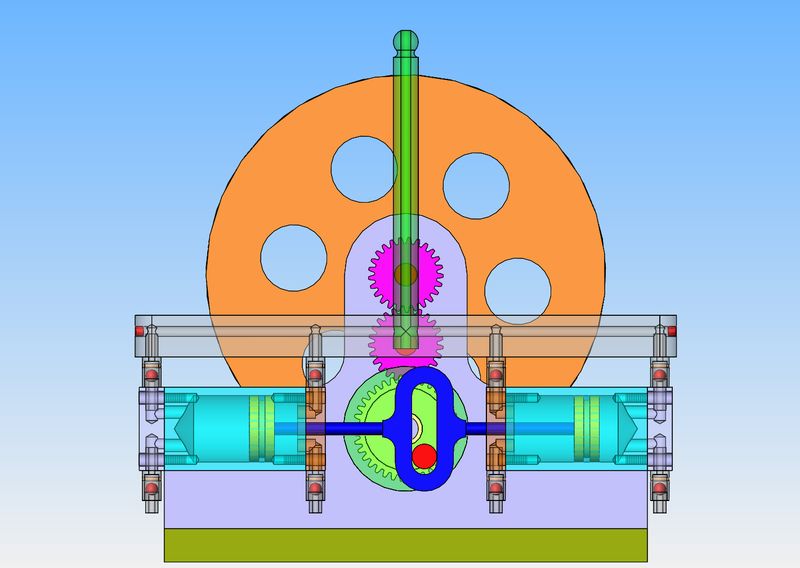

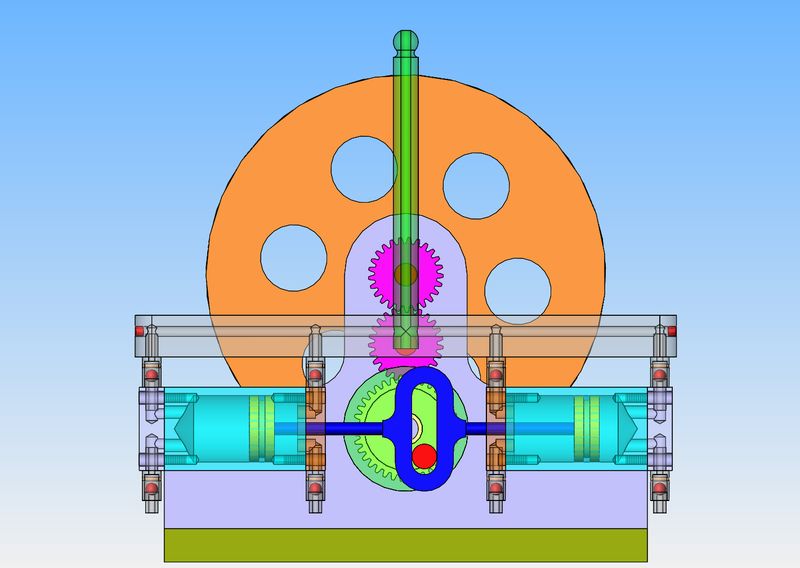

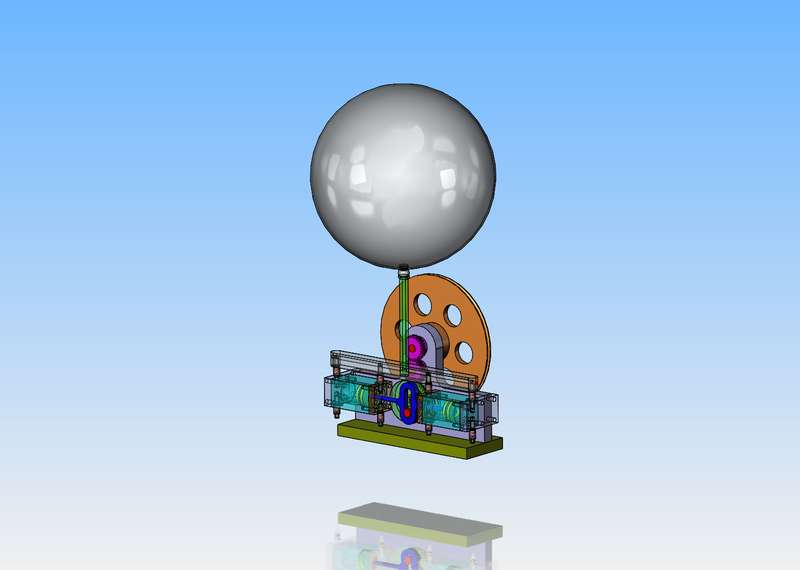

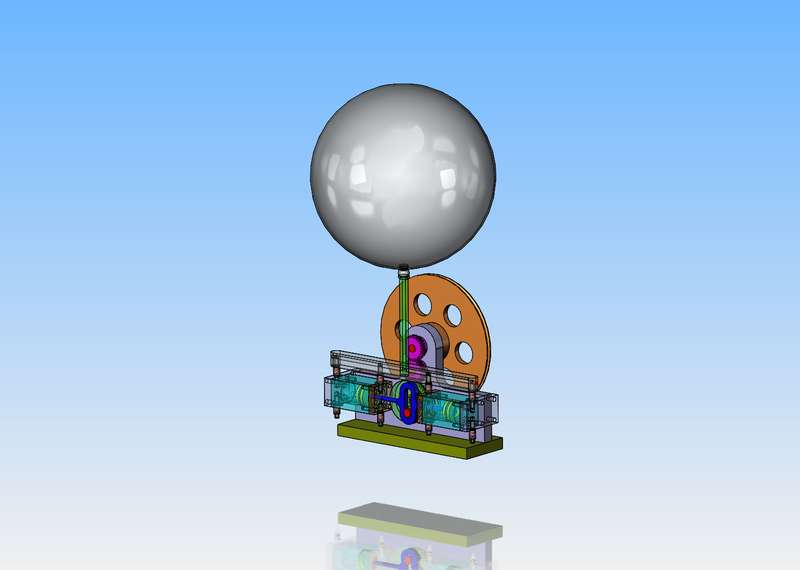

I never did get my "auto-reversing mechanism" to work. However, nothing gets wasted here. There may be a way to incorporate this gear cluster into a compressor.---Thinking----thinking---

vederstein

Must do dumb things....

- Joined

- Feb 26, 2011

- Messages

- 917

- Reaction score

- 744

I like slinky treadmills....

I've written some arduino code in the past that controlled a steam throttle via a stepper motor. It measured shaft speed then opened and closed the throttle as required. It wasn't a full PID control, but it got the job done for my case.

...Ved.

I've written some arduino code in the past that controlled a steam throttle via a stepper motor. It measured shaft speed then opened and closed the throttle as required. It wasn't a full PID control, but it got the job done for my case.

...Ved.

- Joined

- Sep 2, 2011

- Messages

- 1,342

- Reaction score

- 360

i realize this susggestion isn't a compressor, but when I first saw (as a kid) an I believe its called an archamedes screw pump. I was fascinated by it when I was little and still am today. maybe some copper tube and a gear reduction to drive it? just tossing in my own wishes here.

and on the compressor, I believe I saw a balloon pump on the web somewhere made by a machinist, If you havnt already seen it ill try to find a link for it.

and on the compressor, I believe I saw a balloon pump on the web somewhere made by a machinist, If you havnt already seen it ill try to find a link for it.

Okay--This looks promising---

[ame]https://www.youtube.com/watch?v=HhX-8RyP214[/ame]

[ame]https://www.youtube.com/watch?v=HhX-8RyP214[/ame]

Hoo Boy----

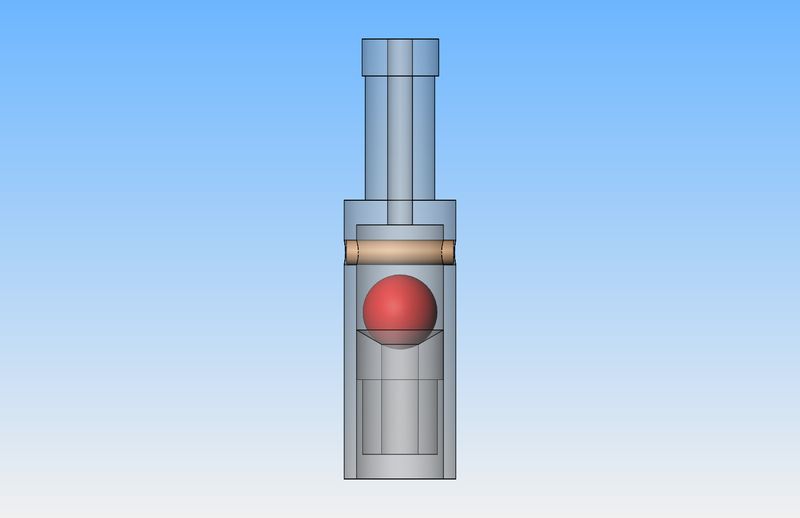

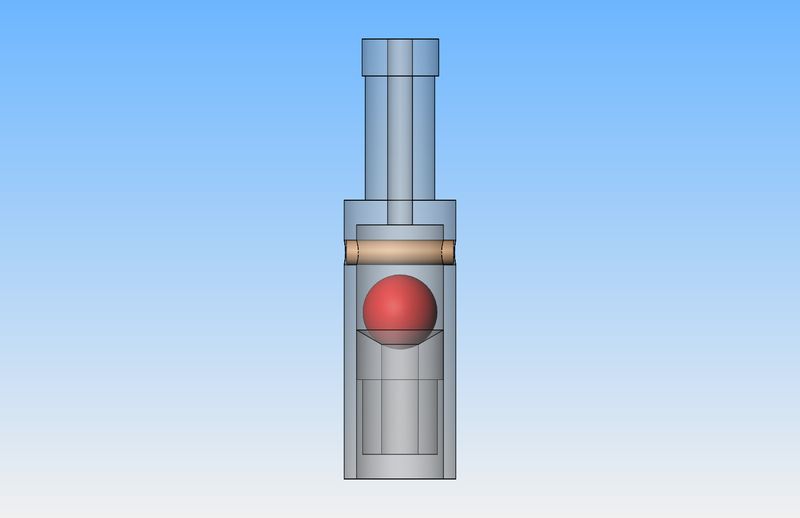

I'm going to need 8 of these guys. Four for air being sucked into the cylinders to keep it from flowing back out when the piston reverses it's travel, and four for air going out of the cylinder to the balloon to prevent the air flowing back from the balloon into the cylinder. The "incoming air" units are all "stand alone". The "outgoing air" units will all be plumbed to a common spigot where the balloon attaches. There is some "gravity effect" with this type of valve, so all eight will have to be installed "right side up".

Might be a good place to use nitrile or ptfe balls. So long as you use the coned seat shown in your drawing. (If you use steel or bronze balls, I think a square edge seat would be better.)

Also, what MJM460 said on MEM about clearance vols. Won't matter much for blowing up balloons though, but then

again good design is often no harder.

Also, what MJM460 said on MEM about clearance vols. Won't matter much for blowing up balloons though, but then

again good design is often no harder.

Well---That certainly looks interesting!! I have never built a Scotch Yoke mechanism before. I can recycle three of my gears and one large pulley from the "Auto-reversing mechanism" that didn't work.

That should do it---

Brian,

Any thought of a relief valve to let the balloon deflate and refill?

Air compressors and water pumps really intrigue me. At some point I would like to have an IC engine driving a compressor and using that air to run an air engine. In time I guess.

Watching from afar as always,

GJ

Any thought of a relief valve to let the balloon deflate and refill?

Air compressors and water pumps really intrigue me. At some point I would like to have an IC engine driving a compressor and using that air to run an air engine. In time I guess.

Watching from afar as always,

GJ

No--I'll blow the balloon up, then see if it bleeds back down past the pistons overnight. If not, I'll pop the balloon.

They should.Shouldn't your check valves keep it isolated from the pistons?

Similar threads

- Replies

- 4

- Views

- 2K

- Replies

- 1

- Views

- 869

- Replies

- 13

- Views

- 3K