zeusrekning

Well-Known Member

- Joined

- Dec 21, 2007

- Messages

- 448

- Reaction score

- 0

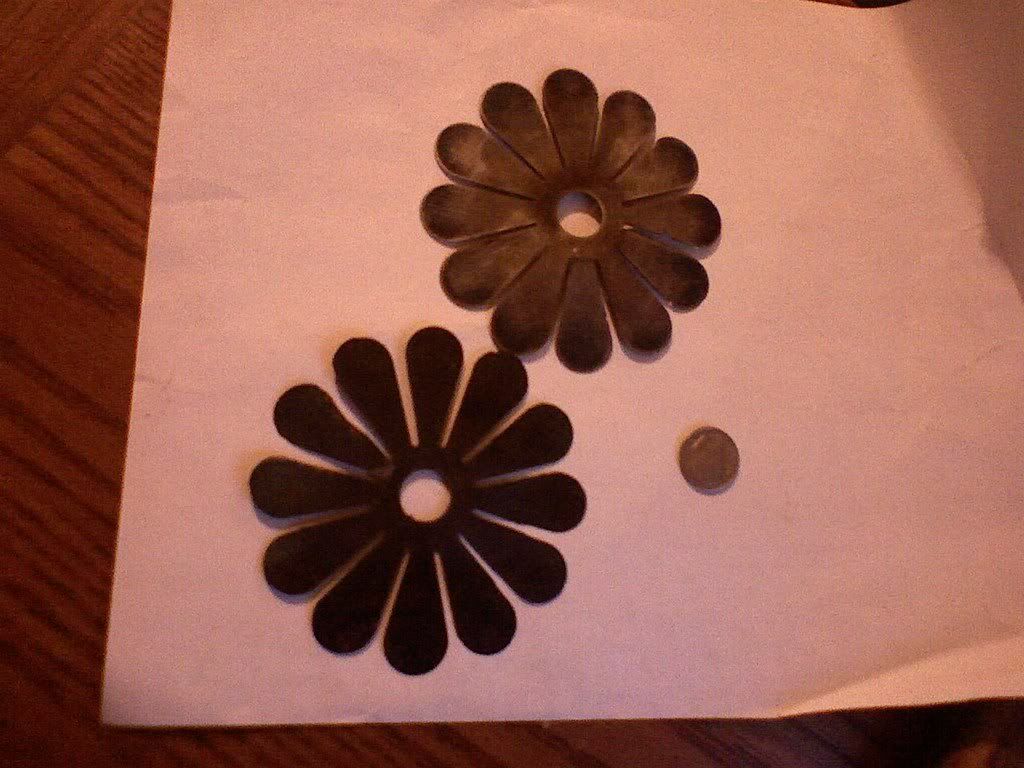

This is a simple method for cutting any shape out of shim stock. I did this for cutting a reed valve out of .006" spring steel shim.

Materials needed: Shim stock, quality spray paint, scribe, scrap plate of stainless or carbon steel, warm salt water, 12volt power supply (battery charger),

1: Scuff surface using fine sandpaper then clean matl. well. You don't want any oil, rust, or fingerprints on the surface.

2: Paint sheet of shim matl. front, back and edges using a quality paint. Automotive undercoating works well.

3: Use a scribe to layout shape of finished part. Scribe only one side. (I made a fixture to clamp the shimstock flat in a CNC mill then engraved the shape I wanted in the paint.)

4: Scrape the paint off one corner of the sheet.

5: Prepare a plastic bucket with warm salt water.

6: Using a 12volt power supply ( I used a car battery charger) attach the negative terminal to the scrap steel plate (the cathode).

7: Attach the positive terminal to the shim stock where the paint was removed.

8: Submerge both into the bucket making sure there is no way the two can contact each other. You will want the side you scribed to face the cathode.

9: Also make sure the corner of shim that you removed the paint from and attached the electrode to is not submerged.

10: Turn on the power supply. The lower the amperage the better of a cut you will get. The higher the amperage the faster it will finish but you will have more undercutting.

11: Occasionally shake the shim stock to loosen the sludge from the scribed lines.

The time will vary depending on the thickness of the shim and the amperage you etch at. It took me about 15 minutes. The whole process start to finish was about two hours, but this included making a fixture to hold the shim in our Fadal and to program the feature I was cutting.

Hope this helps someone. It is alot easier than it sounds.

I'll try to post a pic of the reed valve I made.

Materials needed: Shim stock, quality spray paint, scribe, scrap plate of stainless or carbon steel, warm salt water, 12volt power supply (battery charger),

1: Scuff surface using fine sandpaper then clean matl. well. You don't want any oil, rust, or fingerprints on the surface.

2: Paint sheet of shim matl. front, back and edges using a quality paint. Automotive undercoating works well.

3: Use a scribe to layout shape of finished part. Scribe only one side. (I made a fixture to clamp the shimstock flat in a CNC mill then engraved the shape I wanted in the paint.)

4: Scrape the paint off one corner of the sheet.

5: Prepare a plastic bucket with warm salt water.

6: Using a 12volt power supply ( I used a car battery charger) attach the negative terminal to the scrap steel plate (the cathode).

7: Attach the positive terminal to the shim stock where the paint was removed.

8: Submerge both into the bucket making sure there is no way the two can contact each other. You will want the side you scribed to face the cathode.

9: Also make sure the corner of shim that you removed the paint from and attached the electrode to is not submerged.

10: Turn on the power supply. The lower the amperage the better of a cut you will get. The higher the amperage the faster it will finish but you will have more undercutting.

11: Occasionally shake the shim stock to loosen the sludge from the scribed lines.

The time will vary depending on the thickness of the shim and the amperage you etch at. It took me about 15 minutes. The whole process start to finish was about two hours, but this included making a fixture to hold the shim in our Fadal and to program the feature I was cutting.

Hope this helps someone. It is alot easier than it sounds.

I'll try to post a pic of the reed valve I made.