You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Maryak 10

- Thread starter Maryak

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Will this be a glow plug type engine or the type with the screw in the head.

The screw type, is that a diesel?

Is there a future plane or boat or do you just build them to run on a stand like me.

Sorry if this has already been covered.

The screw type, is that a diesel?

Is there a future plane or boat or do you just build them to run on a stand like me.

Sorry if this has already been covered.

- Joined

- Aug 25, 2007

- Messages

- 3,890

- Reaction score

- 715

This is going to be quite a thumper (I know, that term is usually reserved for 4 strokes), but with that stroke (and bore) you'll have to tie 'er down pretty good to keep it from jumping all over the place!

Chuck

Chuck

Maryak

Well-Known Member

- Joined

- Sep 12, 2008

- Messages

- 4,990

- Reaction score

- 77

Steve,

It will be a diesel type. At this stage I am just building engines and enjoying the process of getting them to run.

Chuck,

How right you are, I am anticipating a fair degree of jumping about. I intend for it not to chase me around the yard. :

Thanks guys for your support and interest. :bow: :bow:

Best Regards

bob

It will be a diesel type. At this stage I am just building engines and enjoying the process of getting them to run.

Chuck,

How right you are, I am anticipating a fair degree of jumping about. I intend for it not to chase me around the yard. :

Thanks guys for your support and interest. :bow: :bow:

Best Regards

bob

Maryak

Well-Known Member

- Joined

- Sep 12, 2008

- Messages

- 4,990

- Reaction score

- 77

Dave and the rest of the support team,

Sorry about the delay but the fang farrier got stuck in yesterday so I rested my aching jaw, ( lucky I am not SWMDBO : )

)

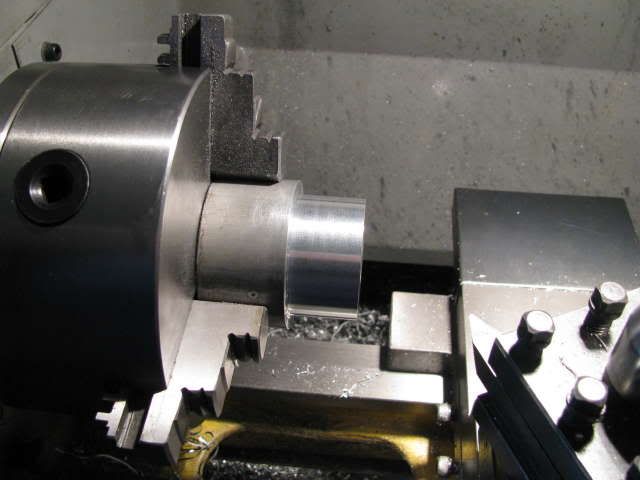

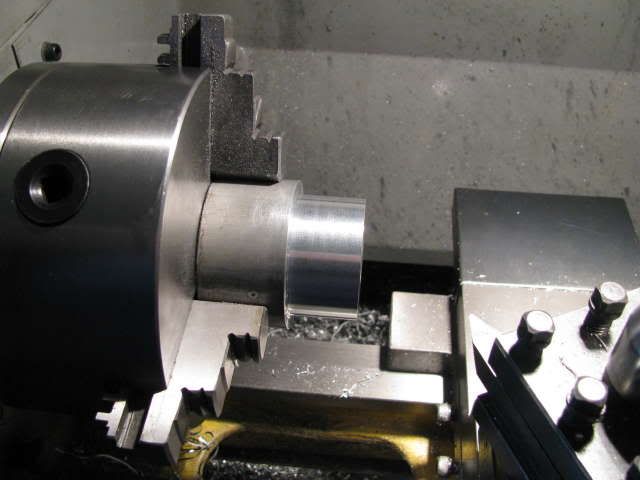

Today's effort was the crankcase cover plate.

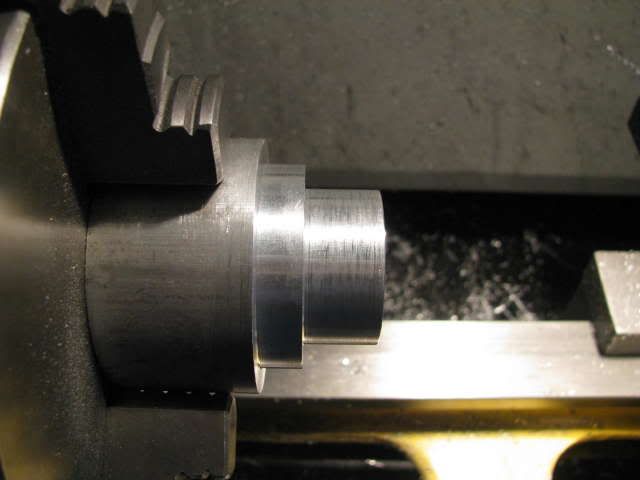

Aluminium chucked for the cover plate

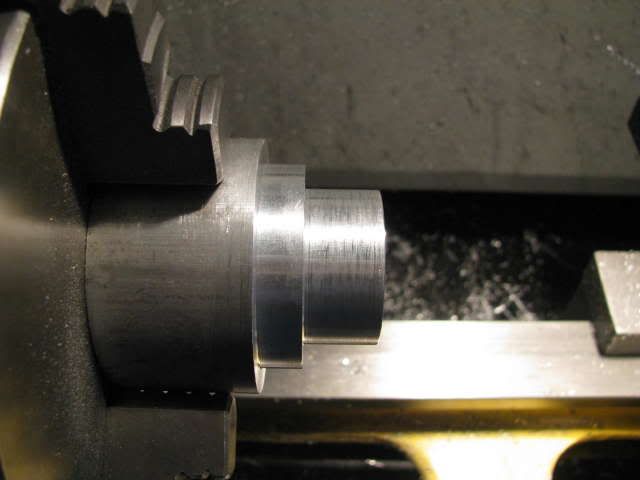

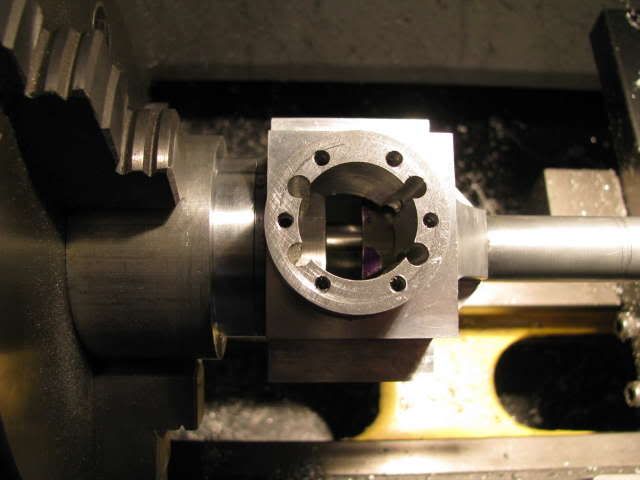

The inside of the plate completed.

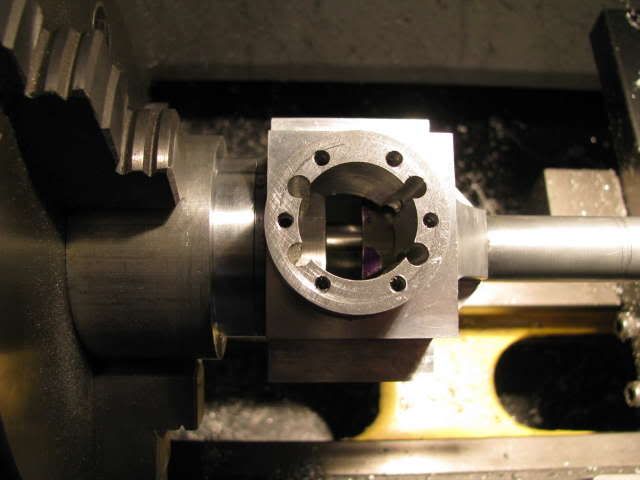

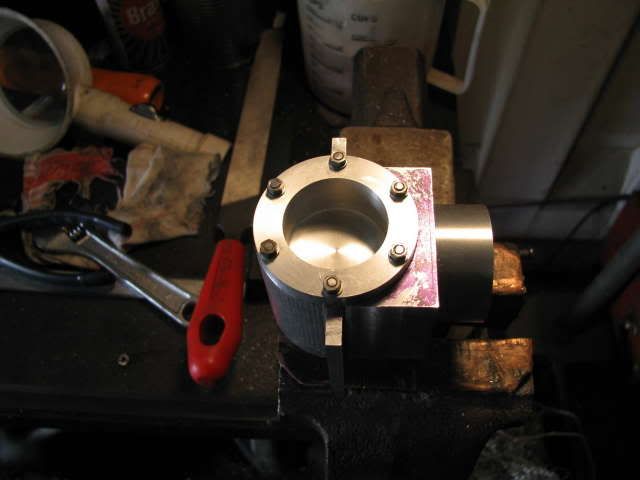

Test fit of the crankcase and cover plate.

Forming the outside flange.

The outside of the cover plate counter bored.

Setup for drilling the cover plate and crankcase.

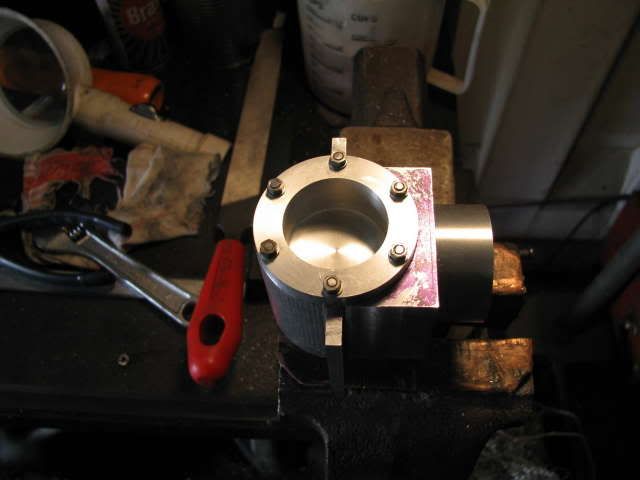

The finished crankcase end cover plate.

Have a good day.

Sorry about the delay but the fang farrier got stuck in yesterday so I rested my aching jaw, ( lucky I am not SWMDBO :

Today's effort was the crankcase cover plate.

Aluminium chucked for the cover plate

The inside of the plate completed.

Test fit of the crankcase and cover plate.

Forming the outside flange.

The outside of the cover plate counter bored.

Setup for drilling the cover plate and crankcase.

The finished crankcase end cover plate.

Have a good day.

tel

Well-Known Member

- Joined

- Feb 8, 2008

- Messages

- 3,293

- Reaction score

- 44

Maryak said:How right you are, I am anticipating a fair degree of jumping about. I intend for it not to chase me around the yard. :

Best Regards

bob

;D Had that happen with a full sized Sundial 1.5hp a few years back - exciting stuff!

Maryak

Well-Known Member

- Joined

- Sep 12, 2008

- Messages

- 4,990

- Reaction score

- 77

tel said:;D Had that happen with a full sized Sundial 1.5hp a few years back - exciting stuff!

Tel,

My worst was one of those ratchet crank handles on a Lister which refused to disengage when the engine started. Not a lot of room to get out of the way in a warboat engine room. When it did let go it was amazing how my things it hit and how many different directions it travelled before coming to a well deserved stop. The fuel shut off was adjacent to it and the emergency shut off was on the other side from where I was trying to disappear into the deck plates. Nough Said

Dave,

Yes thanks it's hovering between 15C and 25C very pleasant.

Thanks to both of you for your continued support. :bow: :bow:

I am 90% sure I will be off to Kalgoolie WA tomorrow, there is an urgent job on a couple of tanks at a mine site, one with Sodium Hydrosulphide and another with Conc Sulphuric Acid. Both are decidedly unpleasant to deal with and I will be glad when it's over. ;D :

Best Regards

Bob

Maryak

Well-Known Member

- Joined

- Sep 12, 2008

- Messages

- 4,990

- Reaction score

- 77

Phil,

I'm glad you find it entertaining. ;D

Today's paltry effort, (getting ready for my trip in the morning).

Tapping the crankcase for the cover plate studs.

Th end cover plate fitted to the crankcase.

Spent quite some time on an aluminium removal exercise from under the benches and machines.

Best Regards

Bob

I'm glad you find it entertaining. ;D

Today's paltry effort, (getting ready for my trip in the morning).

Tapping the crankcase for the cover plate studs.

Th end cover plate fitted to the crankcase.

Spent quite some time on an aluminium removal exercise from under the benches and machines.

Best Regards

Bob

Philjoe5

Well-Known Member

- Joined

- Jul 12, 2007

- Messages

- 1,727

- Reaction score

- 321

Great stuff Bob. :bow: :bow: That crankcase cover extends quite a bit into the crankcase. Why wouldn't you just use a flat plate with a small recess? Are you minimizing dead space in the crankcase with your design?

Cheers,

Phil

Cheers,

Phil

- Joined

- Jun 4, 2008

- Messages

- 3,285

- Reaction score

- 630

I have the same question. I will need some sort of cover for the crankcase on my CO2 engine. Dave Kerzel shows one on his build page, but not on the plan. I was thinking that it might be interesting to have a lexan or polycarbonate transparent cover so expose the operation of the crank and rods. For now I will likely just have an aluminum cover similar to Bob's.

rklopp

Well-Known Member

- Joined

- Oct 6, 2008

- Messages

- 375

- Reaction score

- 89

On a 2-cycle engine like the Maryak10, the crankcase is the scavenging pump. It performs best when it has the least dead space. Hence the deeply dished end cover. I made a Little Dragon and over-cut the crankcase interior volume when slotting for the con-rod clearance. Performance was definitely affected.

Maryak

Well-Known Member

- Joined

- Sep 12, 2008

- Messages

- 4,990

- Reaction score

- 77

rklopp said:On a 2-cycle engine like the Maryak10, the crankcase is the scavenging pump. It performs best when it has the least dead space. Hence the deeply dished end cover.

Phil & kvom,

The above explains it very nicely.

Thanks to all 3 of you for your interest and support. :bow: :bow: :bow:

See Ya next week after Kalgoolie.

Best Regards

Bob

Maryak

Well-Known Member

- Joined

- Sep 12, 2008

- Messages

- 4,990

- Reaction score

- 77

tel said:Just don't get caught up in Hay Street!

Hi All,

I'm back - stayed away from Hay street - mind you there was one on the plane going back to Perth yesterday and were I 40 years younger and single.........

The job went well - I condemned the Sodium Hydrosulphide tank and that made everybody happy - They have been unsuccessfully trying to get money for a new one for a year or so. This tank had corroded from 16mm down to 5mm, (5/8" down to 7/32").

Tomorrow should see M10 again.

Best Regards

Bob

Maryak

Well-Known Member

- Joined

- Sep 12, 2008

- Messages

- 4,990

- Reaction score

- 77

Paolo,

Thanks for your continued support and interest, :bow:

Lack of Progress report - don't quite know but I have done my back in. Can't sit, can't stand, can't lay down any and all for any length of time. I am currently a fully paid up member of "Grumpy Old Men." : :

:

Best Regards

Bob

Thanks for your continued support and interest, :bow:

Lack of Progress report - don't quite know but I have done my back in. Can't sit, can't stand, can't lay down any and all for any length of time. I am currently a fully paid up member of "Grumpy Old Men." :

Best Regards

Bob

Similar threads

- Replies

- 115

- Views

- 34K