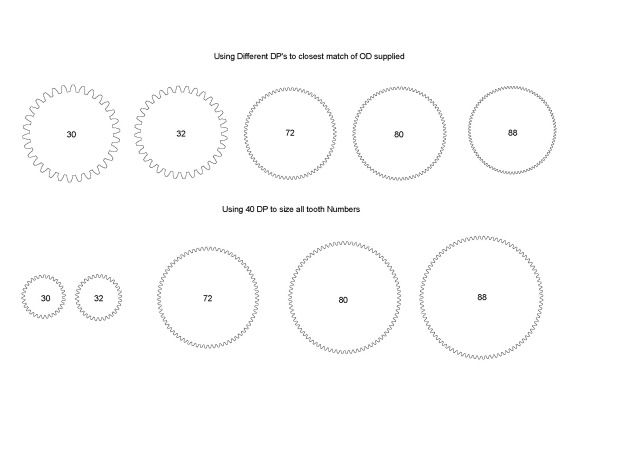

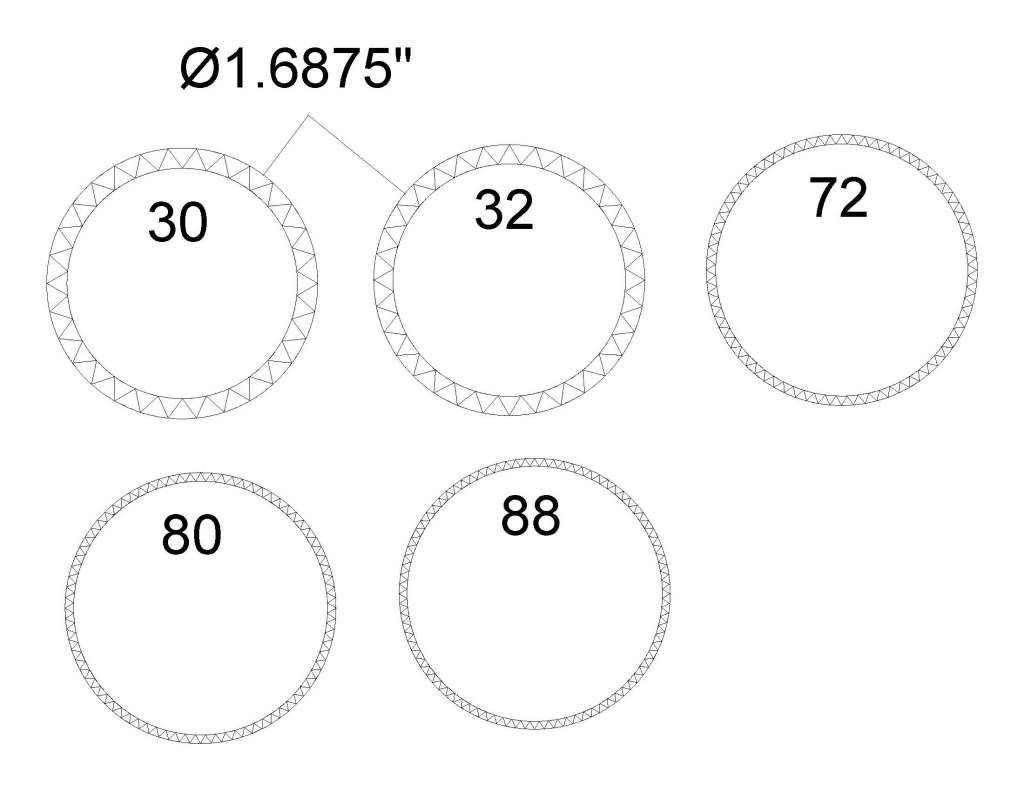

I'm making a few missing index wheels for my faceting machine and while I was able to make the 40 & 48 tooth cogs I still need others. Is there software out there that will let me print out cogs the size and tooth count I need so I can stick them to the brass discs to file them out? Easily done with a 3 corner file as there is shape wise is a 'vvvv' shape and the 2 I have made are good to go so I figure I can make the rest if I can find a way to make the paper patterns. Any ideas?

The reason I'm making them is because money not so much (Aussie pension) time I have plenty of. Also I think the machine maker is gone its an old MDR.

Pete

The reason I'm making them is because money not so much (Aussie pension) time I have plenty of. Also I think the machine maker is gone its an old MDR.

Pete