Longboy

Well-Known Member

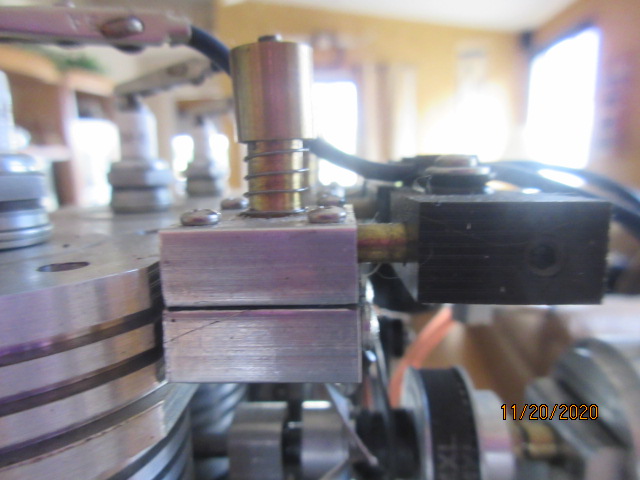

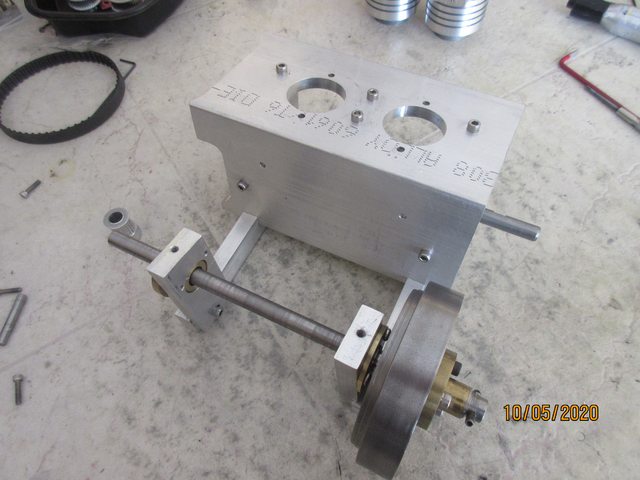

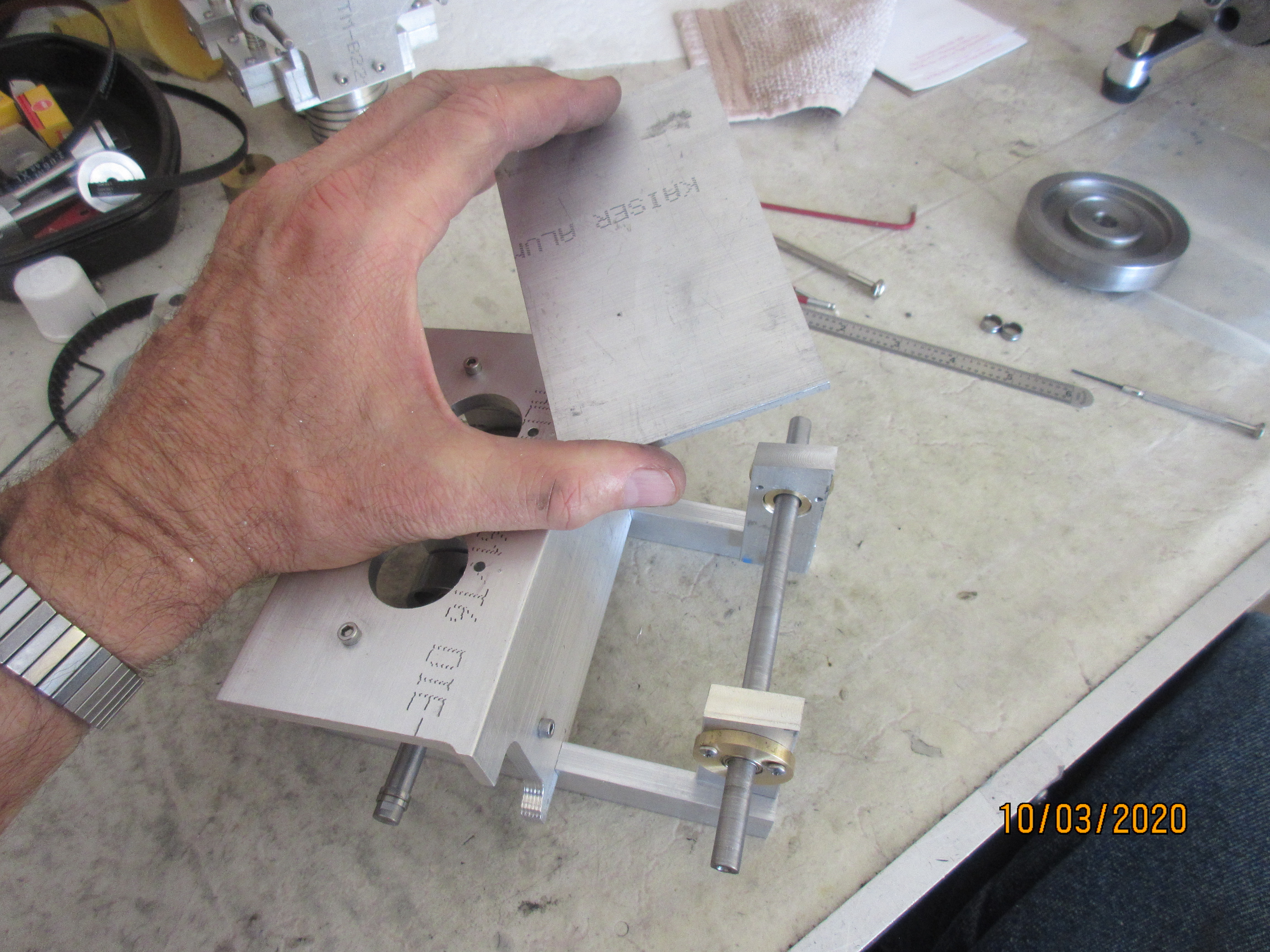

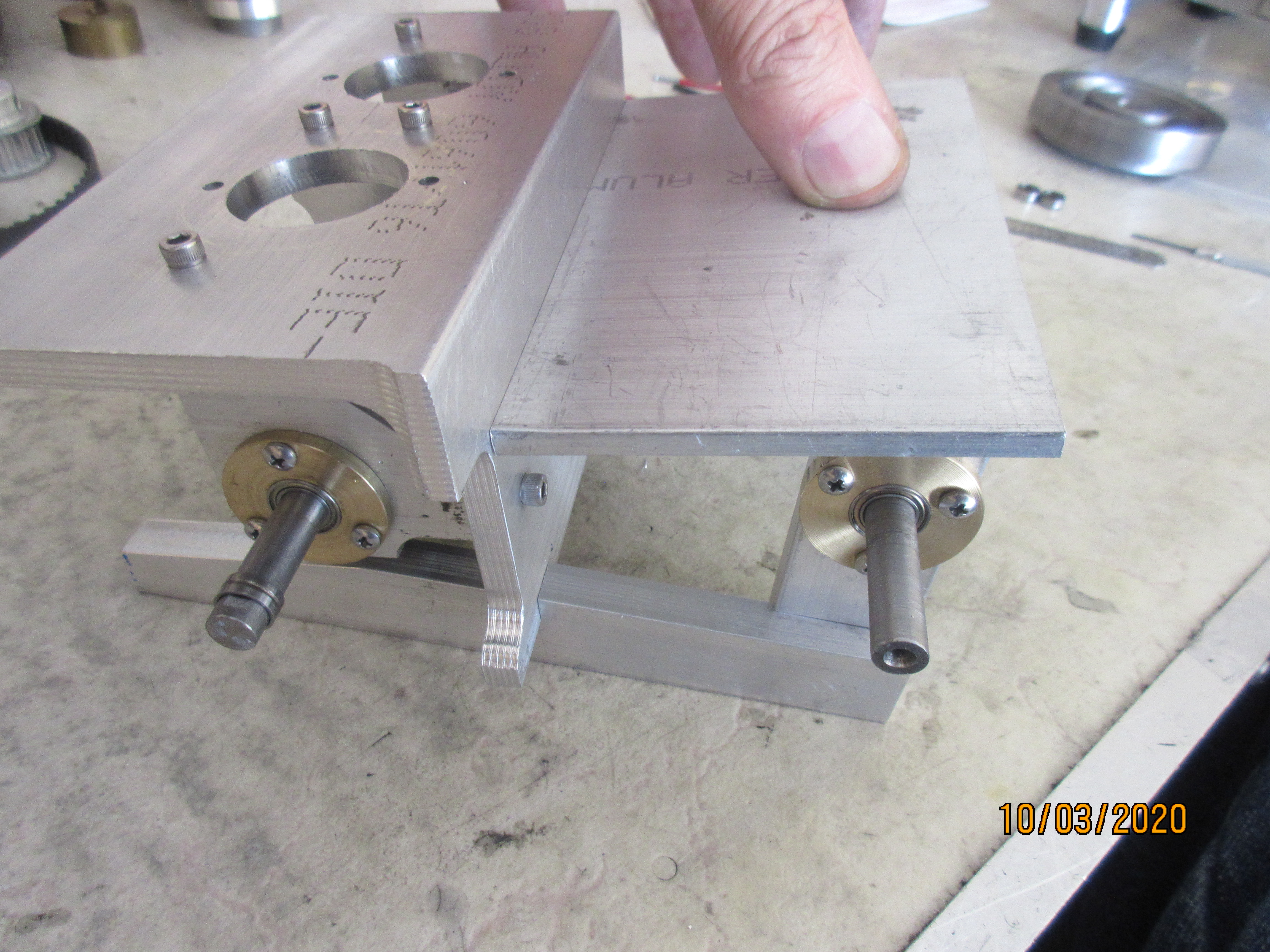

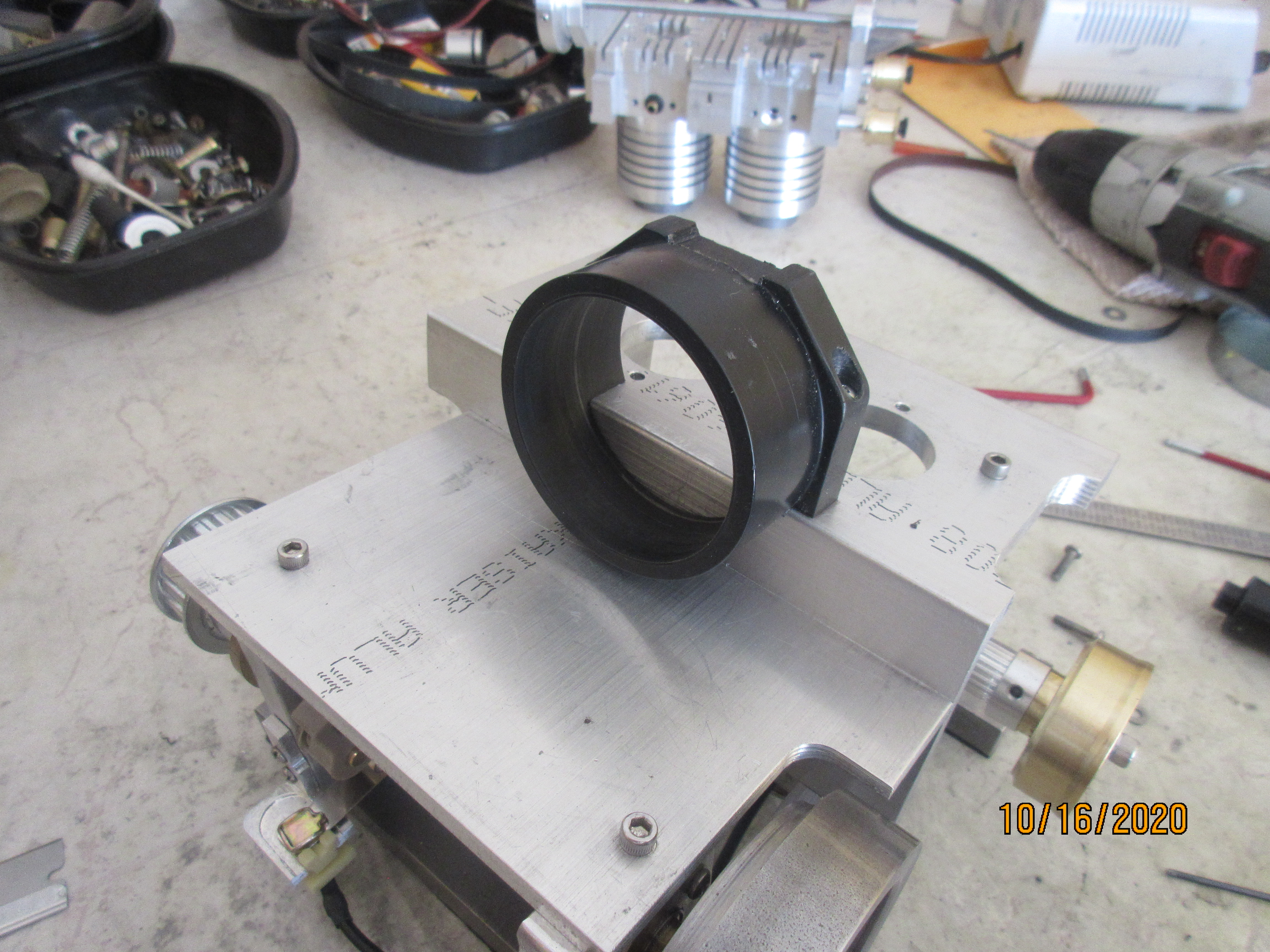

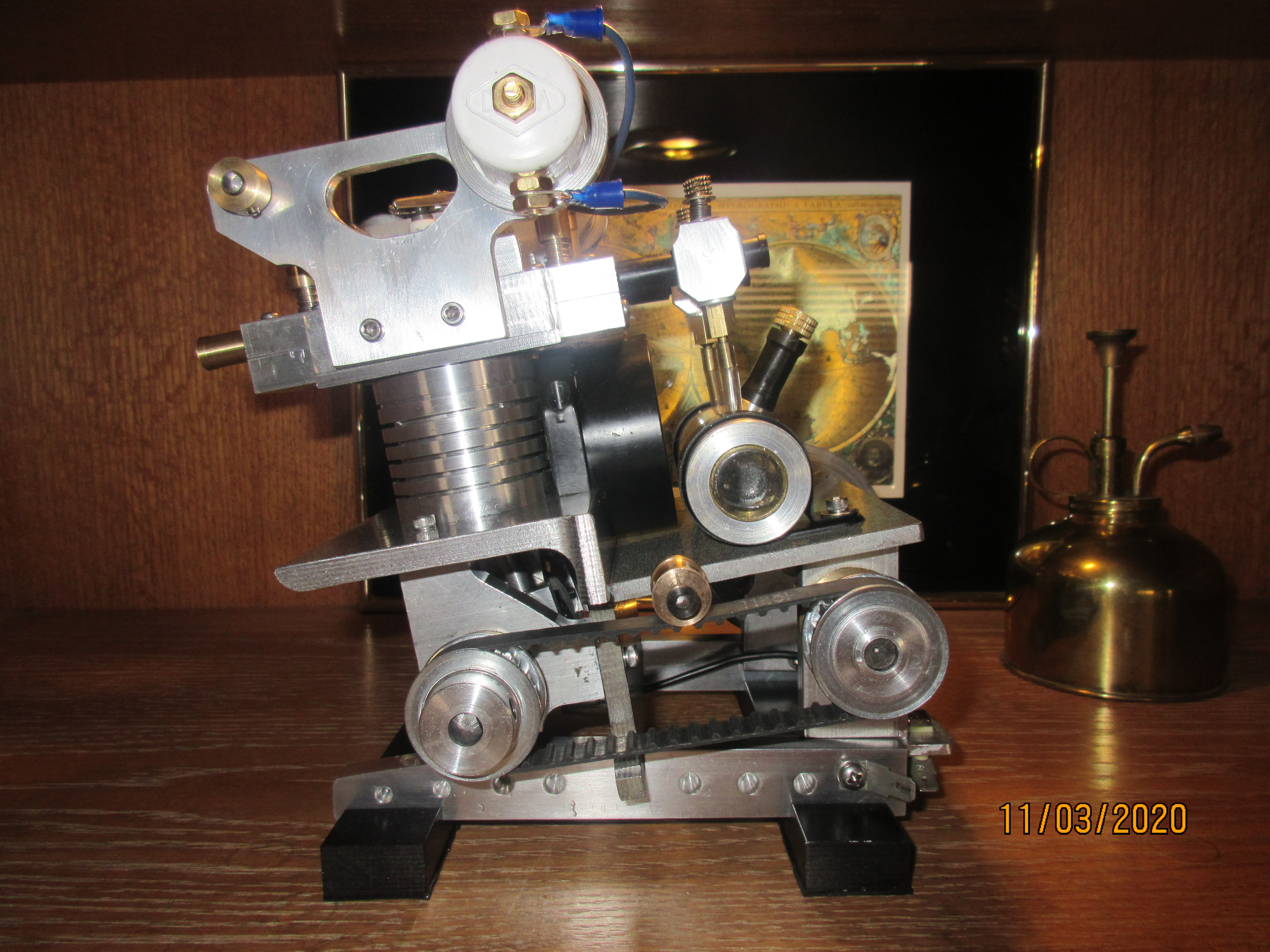

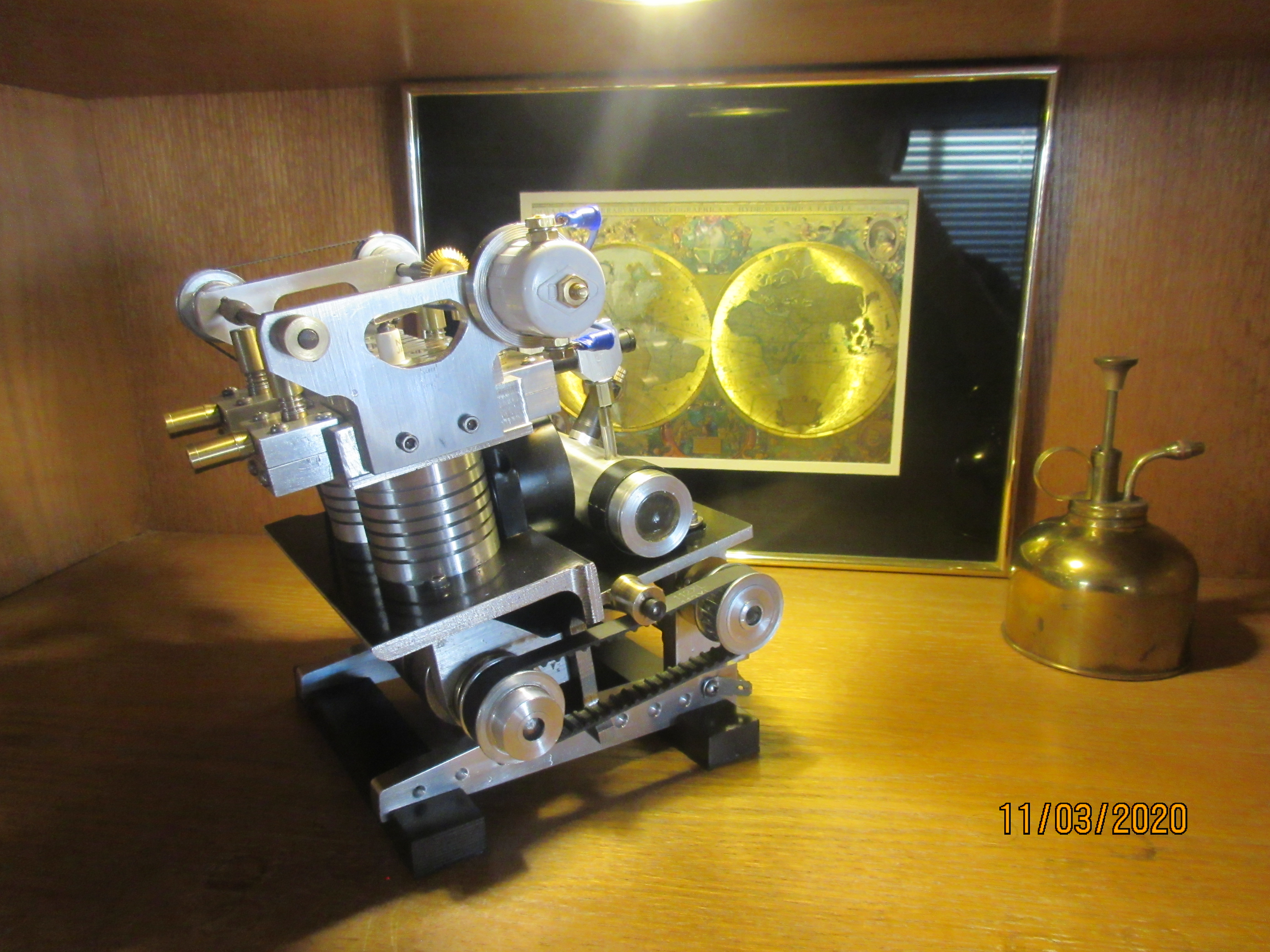

Under the deck, the crankshaft rolls along between the bearing carriers bracketed by 3/8 in. aluminum stock fastened to both the vertical and horizontal legs of the angle frame piece.

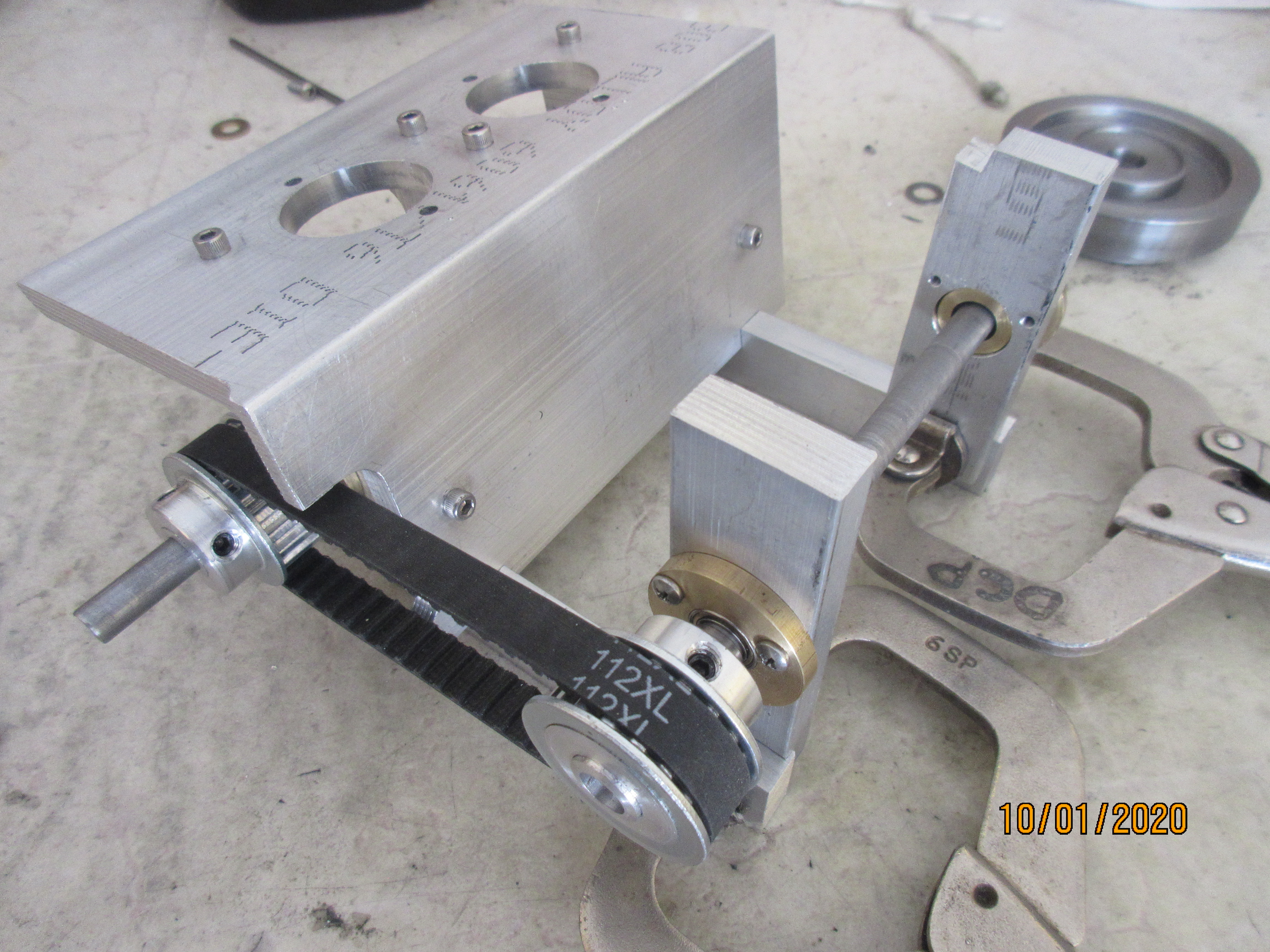

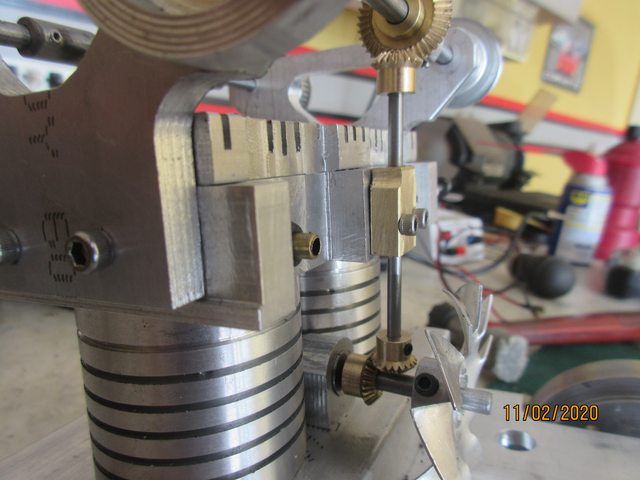

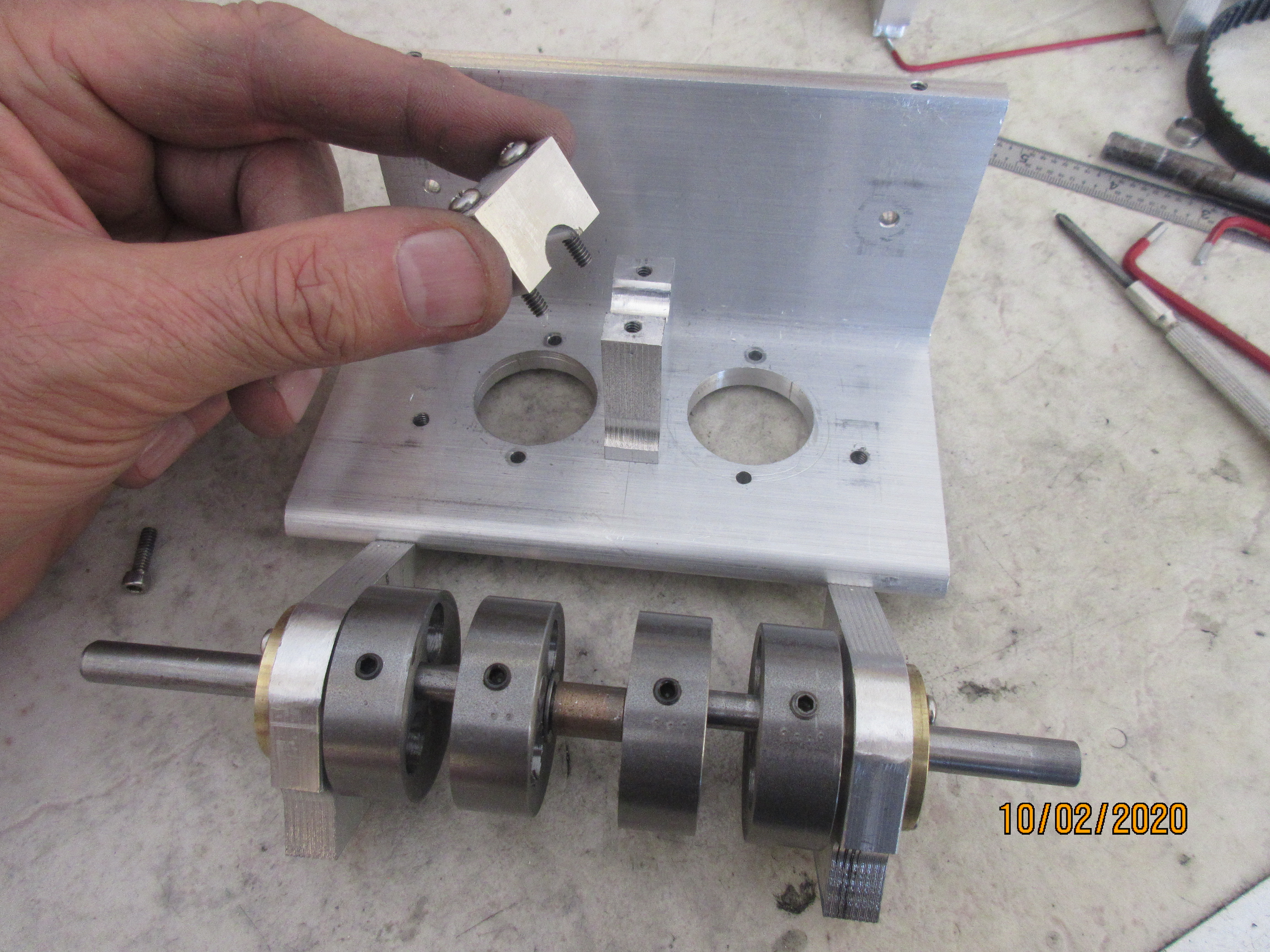

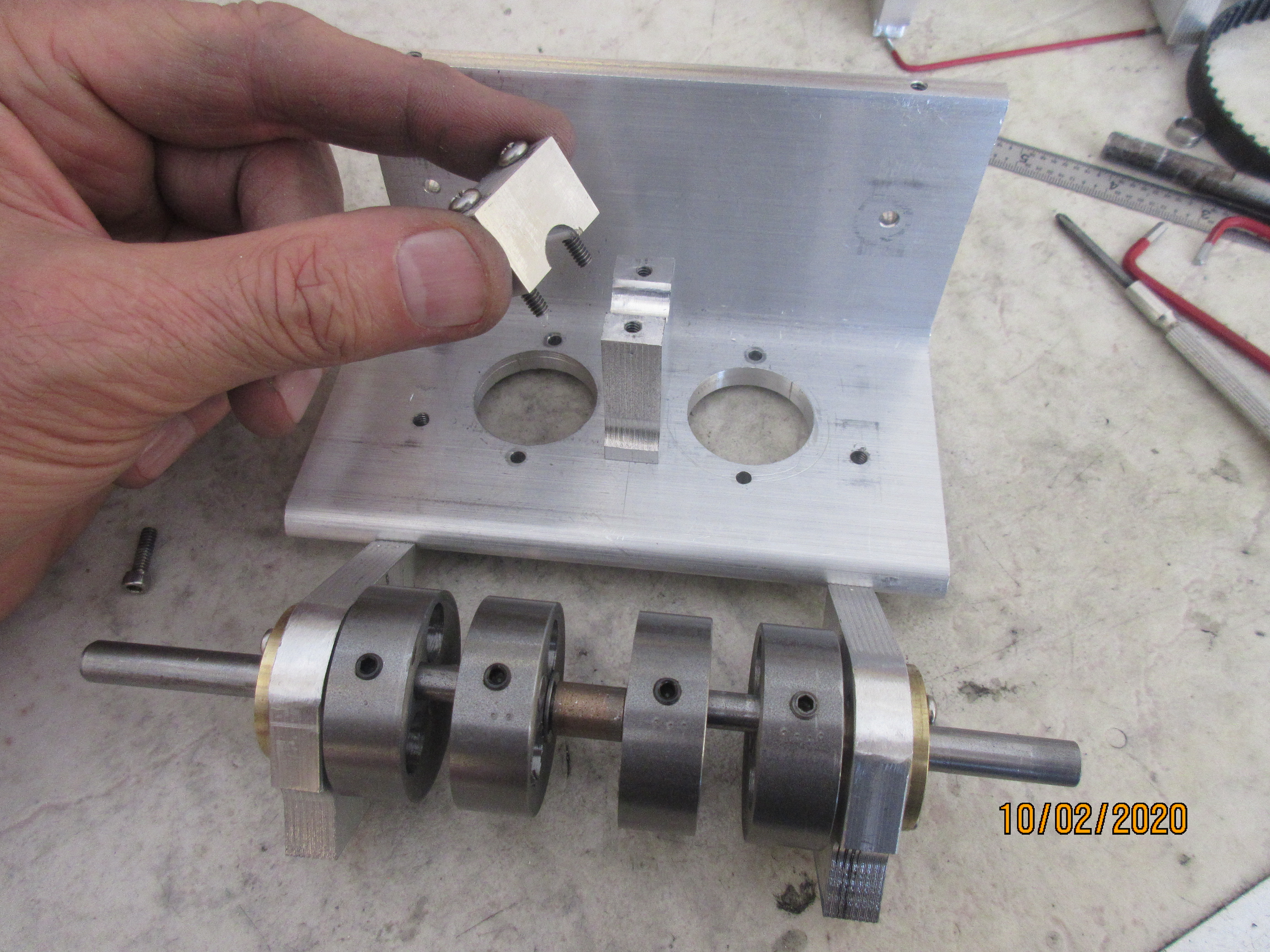

A log of crank webs to be parted off to cage the con rods. These are 1.5 inch diameter with the throw for a .75 in. stroke.

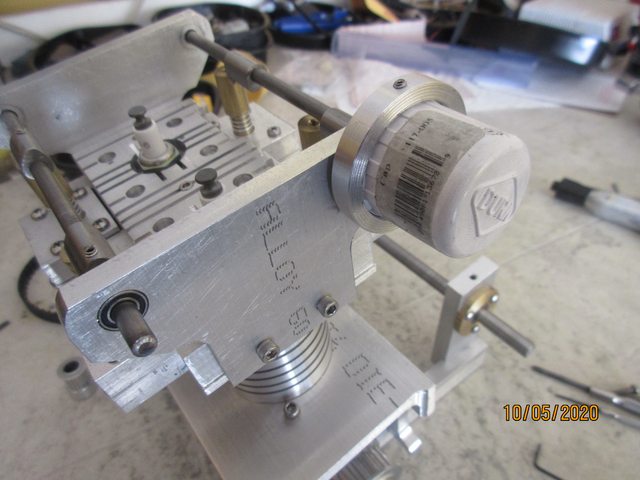

A center bearing of an Oilite bushing for the crankshaft supported by a 1/2 in. wide aluminum tower. R1810ZZ rollers for the brass bearing carriers.

For WEDGE RUNNER, smaller diameter crank webs allow the crankshaft to be placed closer to the top deck plate for a shorter lower end of the engine. The trade off here is that the piston/ rod assembly no longer can be removed or loaded from the bottom of the cylinders as the piston skirt no longer clears the webs.

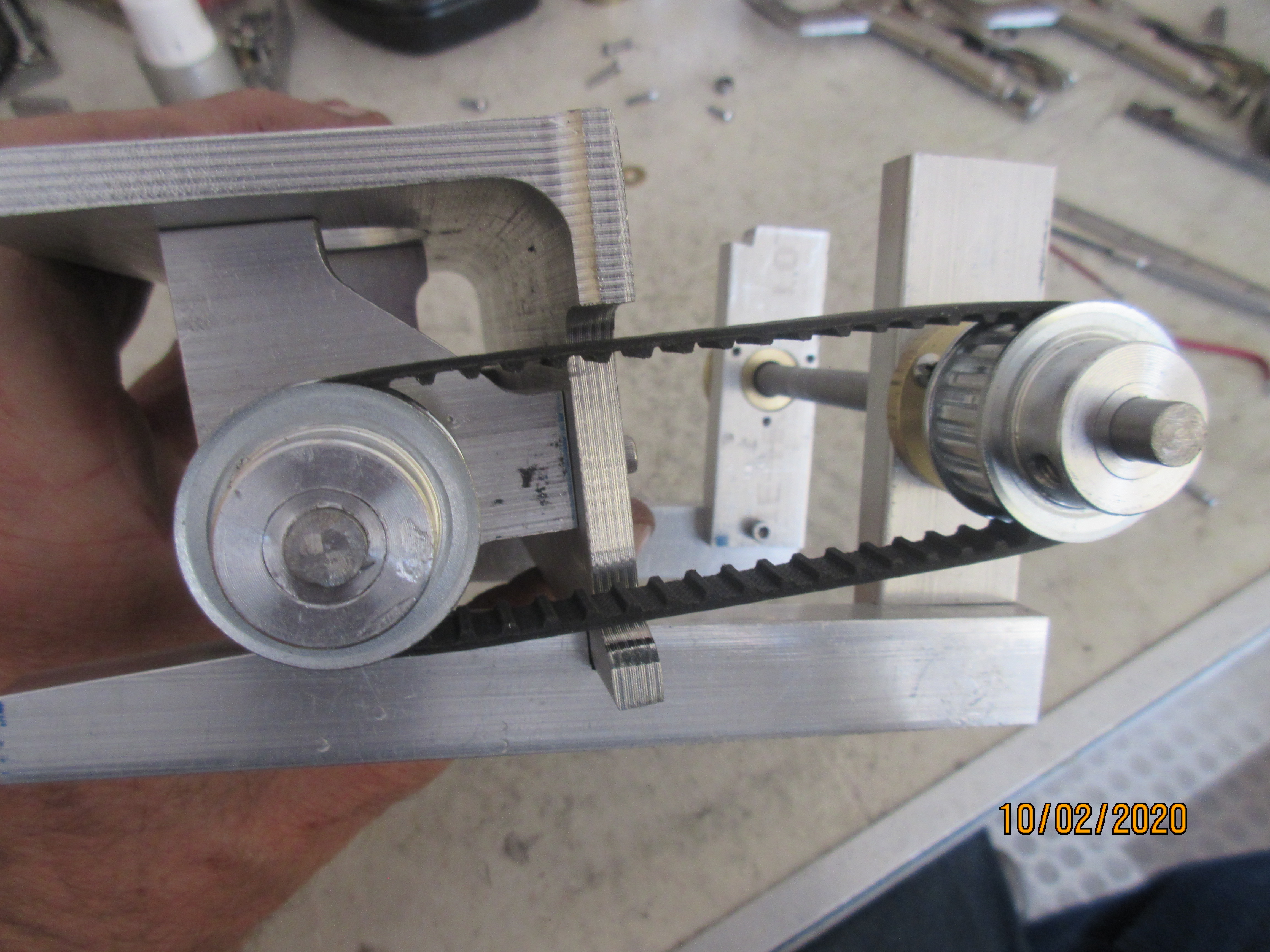

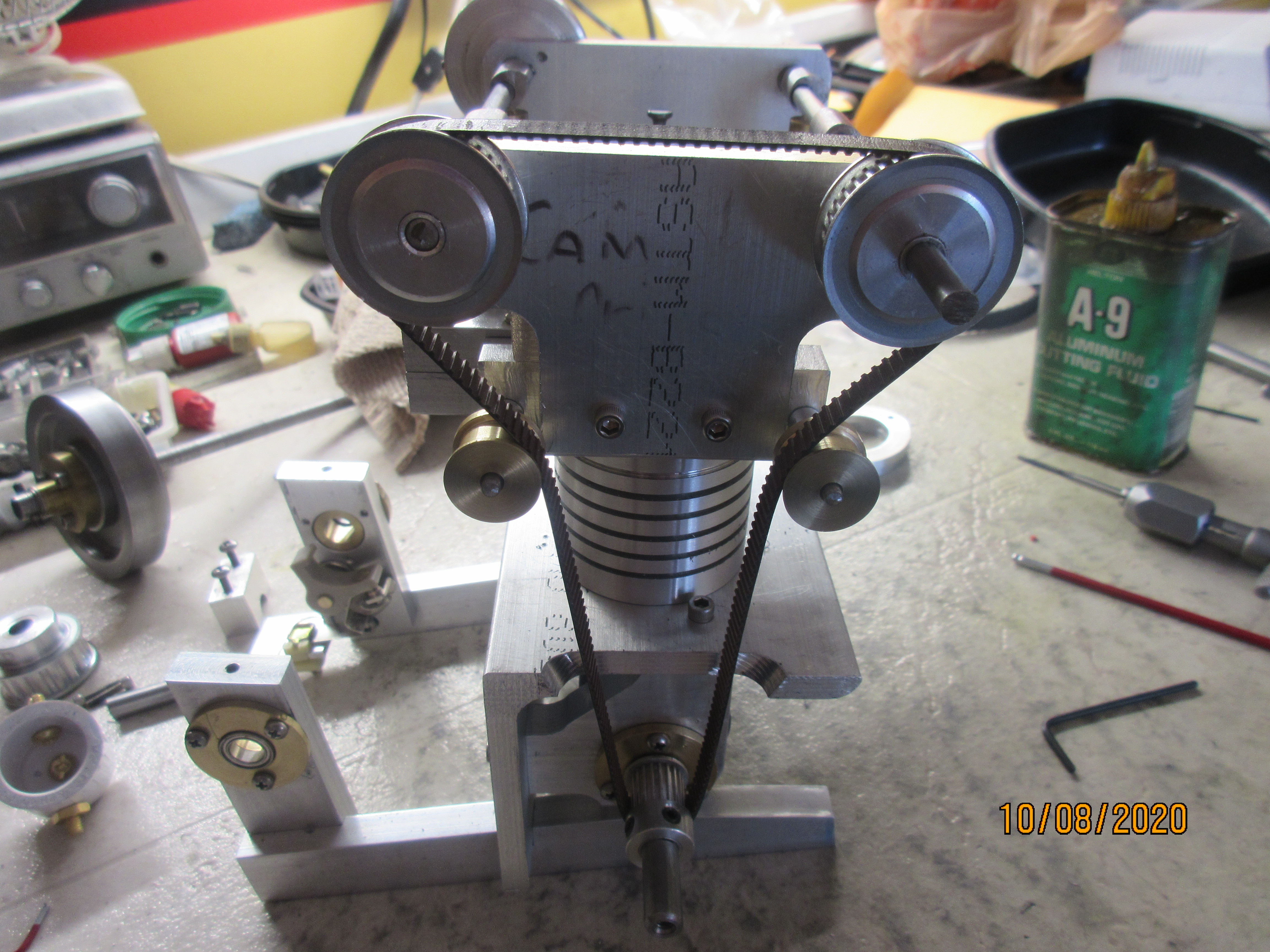

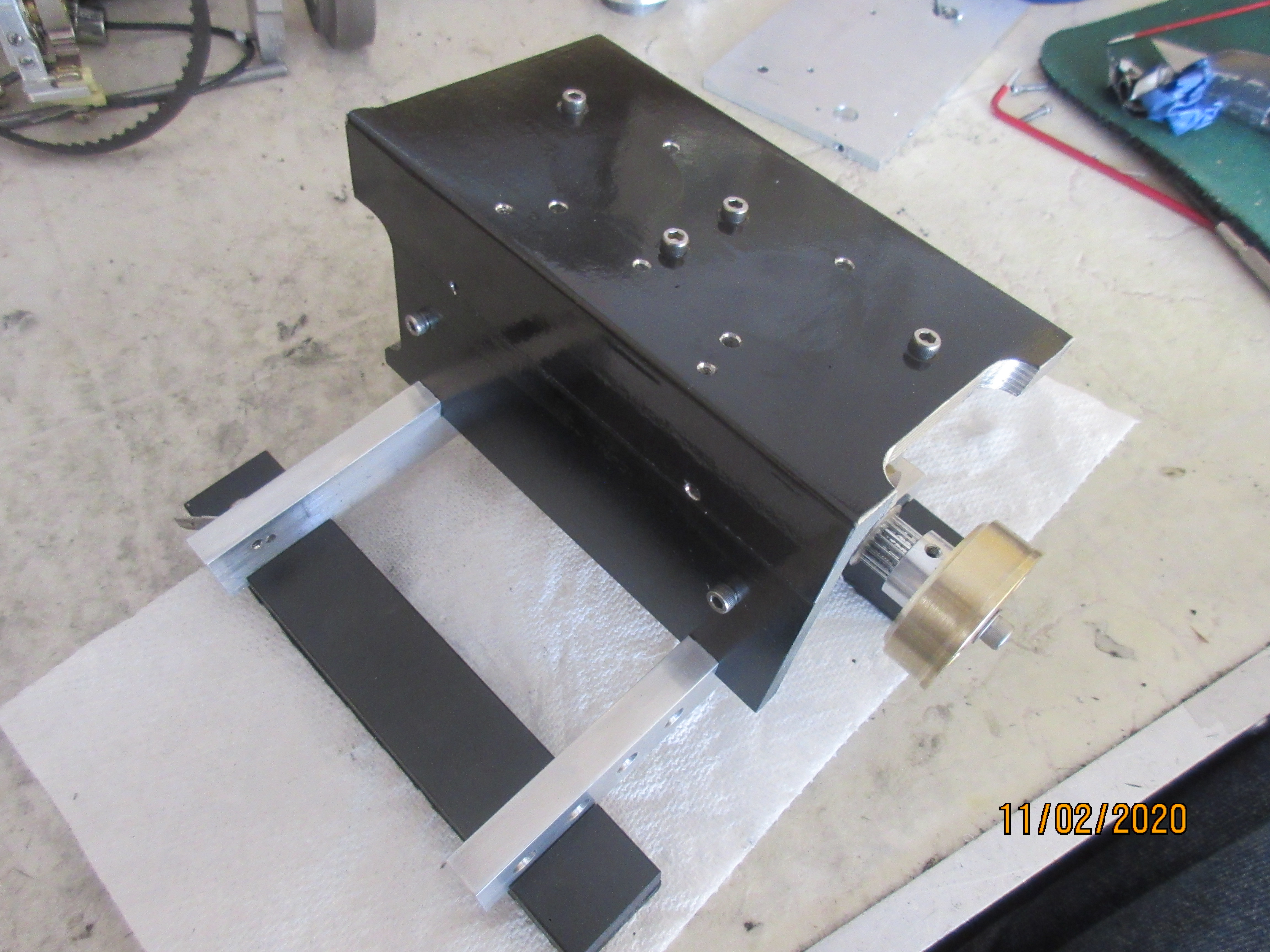

Back to the two screw over a three screw hold down of the cylinders upon the deck, you can see their access between the webs to pull the top of the engine off by disconnecting the cam drive belt. Yes, the crank can be removed to pull the piston/rod too by pulling a drive off of each crank end..... just builder's choice ease here!

A log of crank webs to be parted off to cage the con rods. These are 1.5 inch diameter with the throw for a .75 in. stroke.

A center bearing of an Oilite bushing for the crankshaft supported by a 1/2 in. wide aluminum tower. R1810ZZ rollers for the brass bearing carriers.

For WEDGE RUNNER, smaller diameter crank webs allow the crankshaft to be placed closer to the top deck plate for a shorter lower end of the engine. The trade off here is that the piston/ rod assembly no longer can be removed or loaded from the bottom of the cylinders as the piston skirt no longer clears the webs.

Back to the two screw over a three screw hold down of the cylinders upon the deck, you can see their access between the webs to pull the top of the engine off by disconnecting the cam drive belt. Yes, the crank can be removed to pull the piston/rod too by pulling a drive off of each crank end..... just builder's choice ease here!

Last edited: