SignalFailure

Well-Known Member

- Joined

- Jan 1, 2008

- Messages

- 366

- Reaction score

- 3

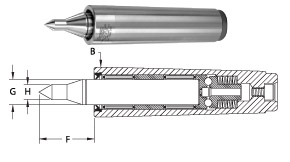

I have a live centre* that came with my mini-lathe 'bundle' but have never had occasion to use it, in fact I didn't really know what it was for! Googling tells me that it is commonly used in CNC and allows higher speeds and greater clamping pressure with no lubrication.

Does it have any use or advantage over a dead centre in day-to-day turning operations or any other application?

TIA

Paul

*Read 'center' if you are longitudinally challenged

Does it have any use or advantage over a dead centre in day-to-day turning operations or any other application?

TIA

Paul

*Read 'center' if you are longitudinally challenged