Powder keg

Well-Known Member

- Joined

- Oct 10, 2007

- Messages

- 1,091

- Reaction score

- 3

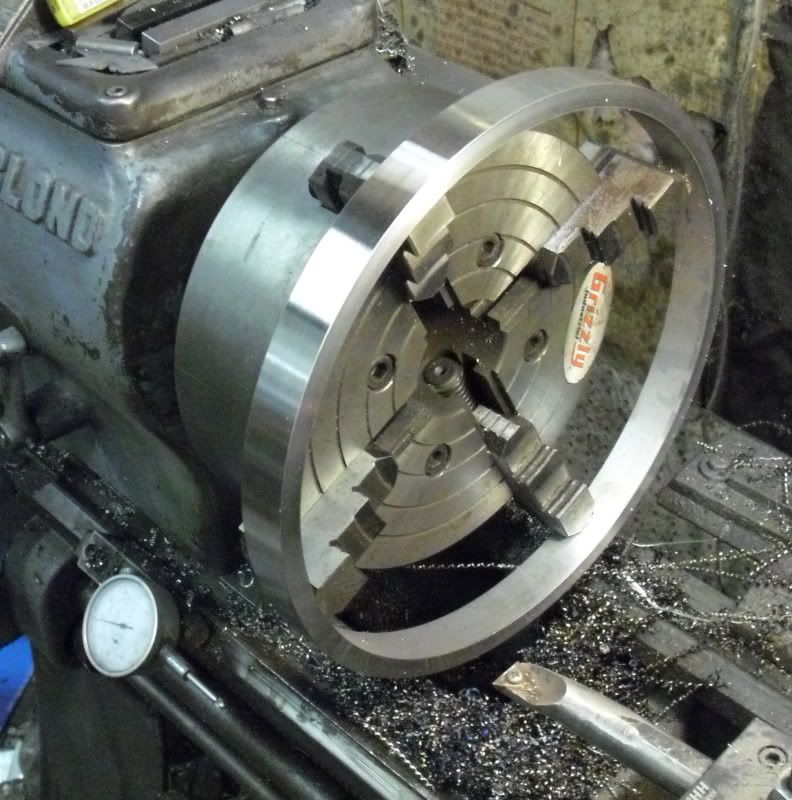

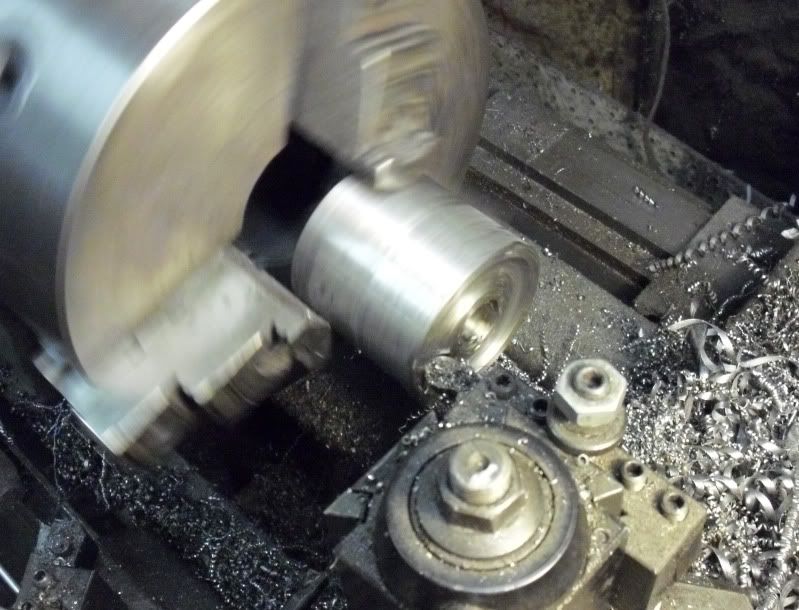

Had a great day in the shop today!!! I chucked up a piece of shaft today and on the inside of it was an old style flat pulley!!! I still have to cut the crown on it though.

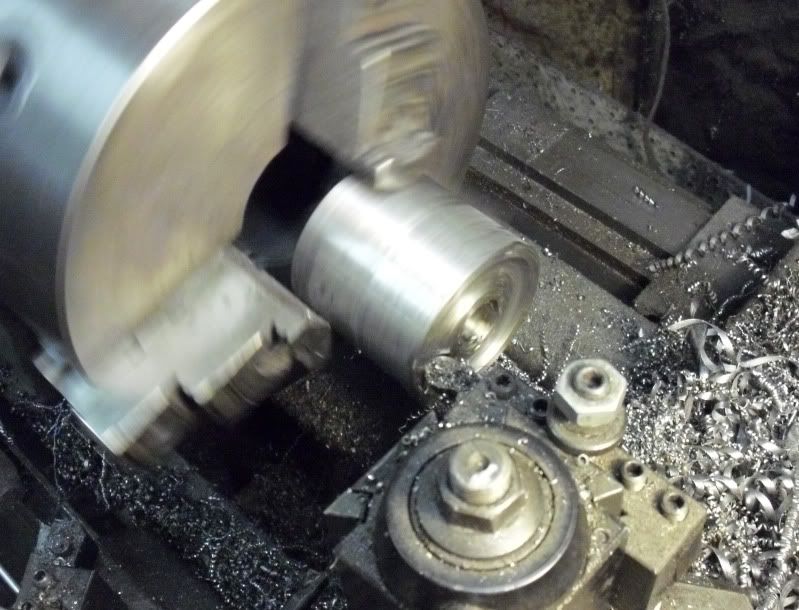

Here Is what I have thus far. I need to make a couple of set screws for the tight pulley and clean some more.

I need to get some flat bar for the tool rests. The originals are long gone now ( That will be a fun lathe project!!!

( That will be a fun lathe project!!!

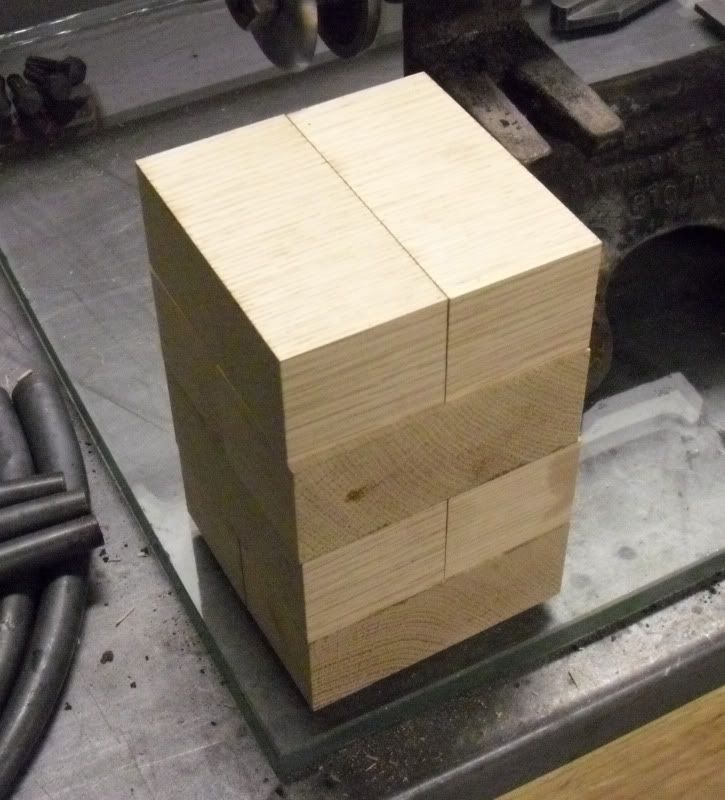

Now on to the pulleys for the line shaft\o/

Here Is what I have thus far. I need to make a couple of set screws for the tight pulley and clean some more.

I need to get some flat bar for the tool rests. The originals are long gone now

Now on to the pulleys for the line shaft\o/