Powder keg

Well-Known Member

- Joined

- Oct 10, 2007

- Messages

- 1,091

- Reaction score

- 3

Hey Everyone,

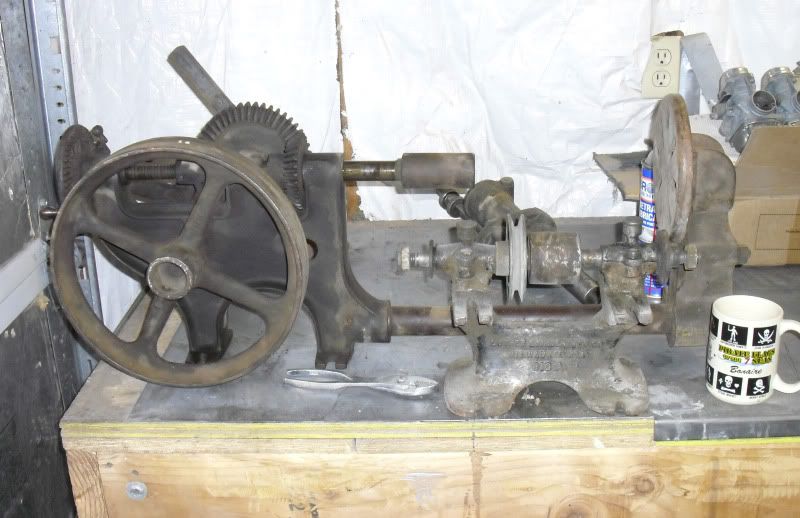

This summer I bought a post drill and I ran across a bench grinder that require flat belts to run them. I've been cleaning my shop and I have a spot for them to live\0/ I found a 1/2 horse industrial motor that I think will run them fine. My problem.....

I was born about 100 years too late :shrug: I am having a bunch of trouble finding much info on the subject. I found a book that I think will get me by. But I thought It would be neat get the info from people that have actually seen/used equipment ran with overhead belts.

I'm planing on fabricating brackets to mount the motor and shafts on the wall behind the equipment. I haven't decided if I'm going to cast them or build them up from bar stock. I've heard that cast iron bearings will outlast bronze bushings many times over.

The drill press has had liberal doses of WD40 applied latly and ticks over like a Swiss watch. The power feed will be nice. The grinder has a broken piece and a couple of pieces missing. They will be easy to fab up from pictures I have.

Thanks for any input, Wes

wEc1

This summer I bought a post drill and I ran across a bench grinder that require flat belts to run them. I've been cleaning my shop and I have a spot for them to live\0/ I found a 1/2 horse industrial motor that I think will run them fine. My problem.....

I was born about 100 years too late :shrug: I am having a bunch of trouble finding much info on the subject. I found a book that I think will get me by. But I thought It would be neat get the info from people that have actually seen/used equipment ran with overhead belts.

I'm planing on fabricating brackets to mount the motor and shafts on the wall behind the equipment. I haven't decided if I'm going to cast them or build them up from bar stock. I've heard that cast iron bearings will outlast bronze bushings many times over.

The drill press has had liberal doses of WD40 applied latly and ticks over like a Swiss watch. The power feed will be nice. The grinder has a broken piece and a couple of pieces missing. They will be easy to fab up from pictures I have.

Thanks for any input, Wes

wEc1