bambuko

Well-Known Member

- Joined

- Nov 3, 2009

- Messages

- 63

- Reaction score

- 1

This just a sanity check ;D

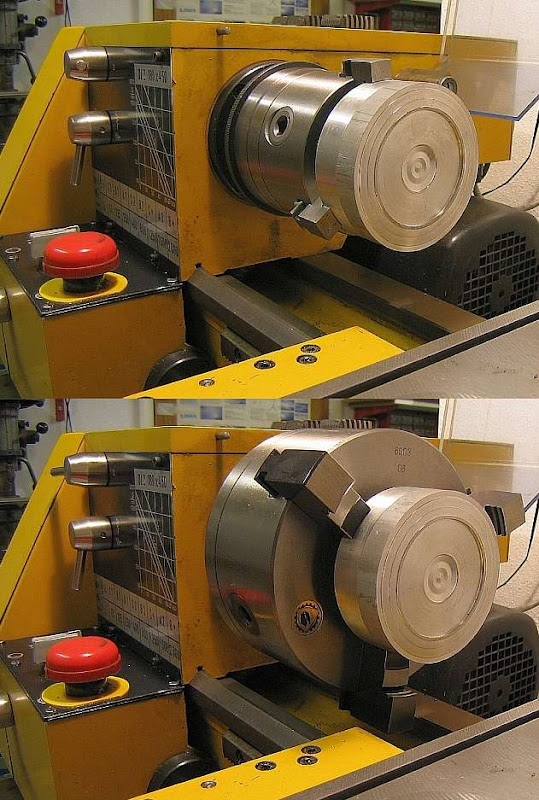

For a 4" centre height lathe (8" swing) what would be the max three jaw chuck you would be prepared to fit and use?

I am talking here EMCO type lathe and it's many clones. They normally are delivered with 4" dia chuck and I would have no hesitation to use 5" chuck, but what about 6" chuck?

Of course I know I can do it (ie it will fit), the question is though - is it a good idea, or should I be concerned about something? (like for example it's weight?).

I am good on theory but often short on practical :-\, so your experience and recommendations would be appreciated - thanks.

but often short on practical :-\, so your experience and recommendations would be appreciated - thanks.

Chris

For a 4" centre height lathe (8" swing) what would be the max three jaw chuck you would be prepared to fit and use?

I am talking here EMCO type lathe and it's many clones. They normally are delivered with 4" dia chuck and I would have no hesitation to use 5" chuck, but what about 6" chuck?

Of course I know I can do it (ie it will fit), the question is though - is it a good idea, or should I be concerned about something? (like for example it's weight?).

I am good on theory

Chris