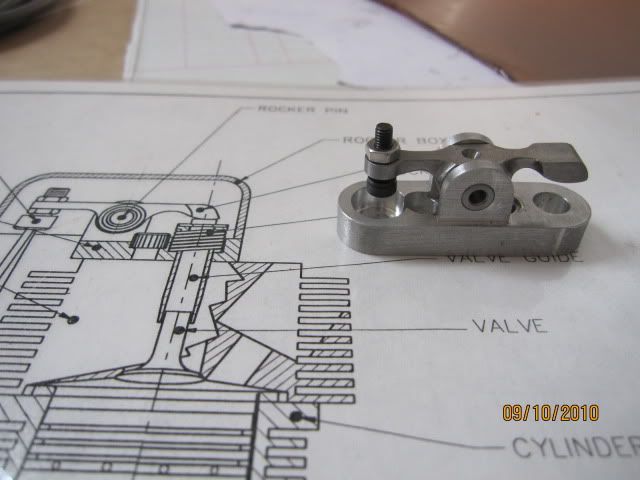

G'Day All i am building a kinner radial from Strictly IC i started it a bout 15 years ago the gave it away until about 4 months ago by chance i found this site and the efforts of people on this site especially Gbritnell with his V twin inspired me to

continue with mine & hopefully finish it i have just completed the cam grinder to do the 5 camshafts the following pic were taken just after i recommenced construction

hope the pix are not too big

Gary

continue with mine & hopefully finish it i have just completed the cam grinder to do the 5 camshafts the following pic were taken just after i recommenced construction

hope the pix are not too big

Gary