Thanks Kel!

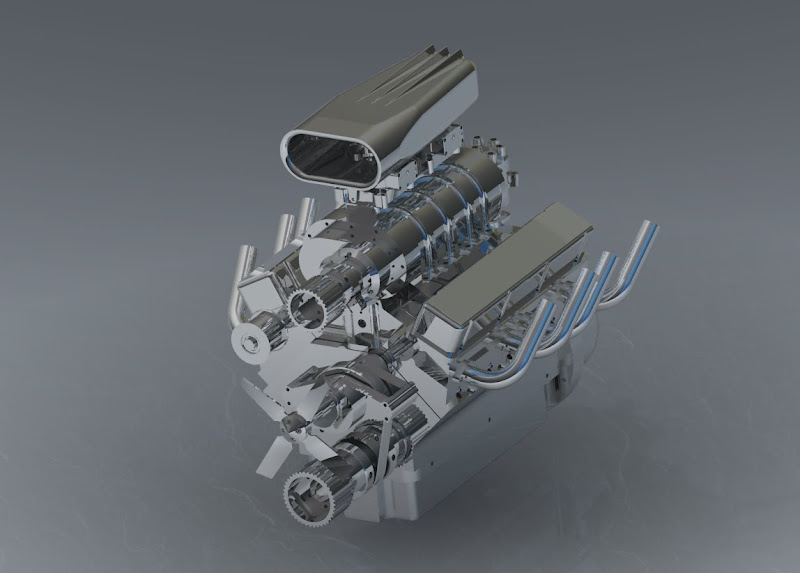

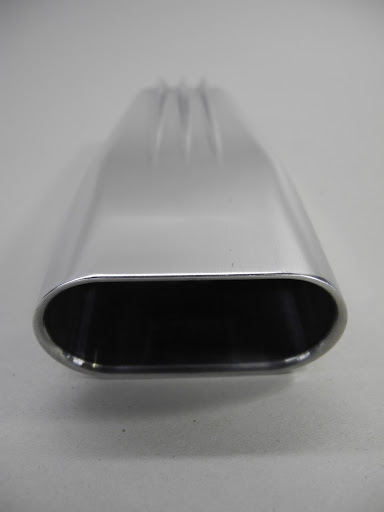

I've been itching to make some chips for this engine so I thought I would start at the top. The blower scoop.

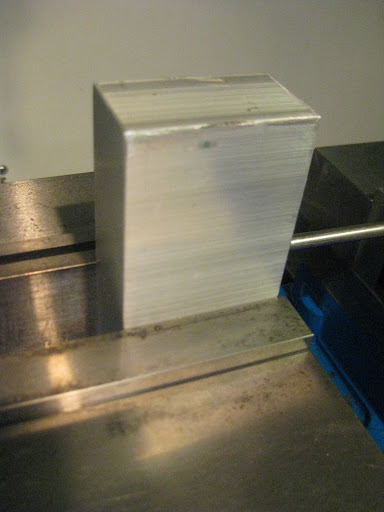

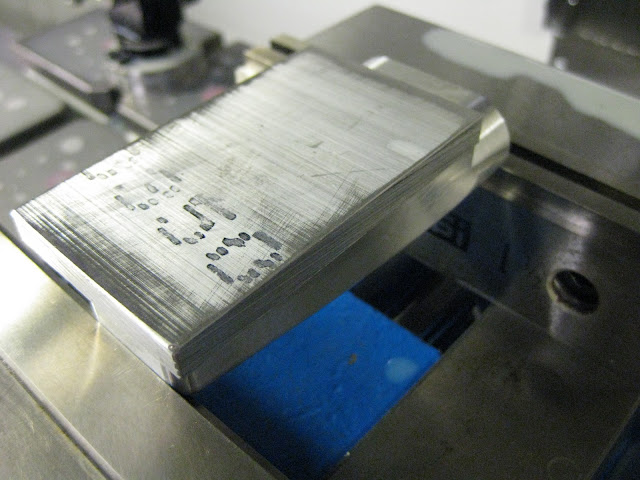

I started with a block in the vise;

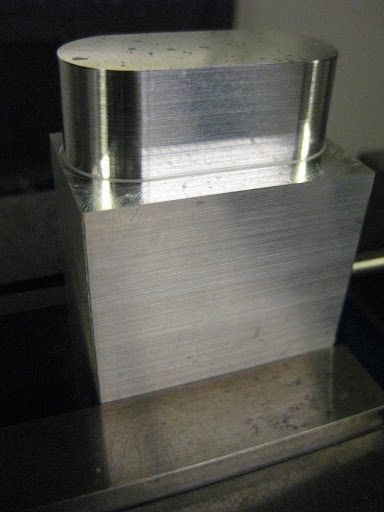

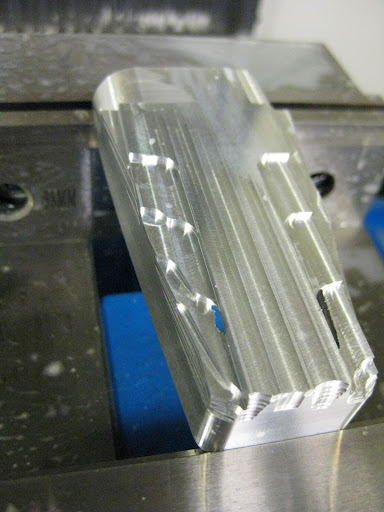

And then finish machined the front outer profile, which was offset to leave some stock for work holding, to establish a datum for subsequent operations;

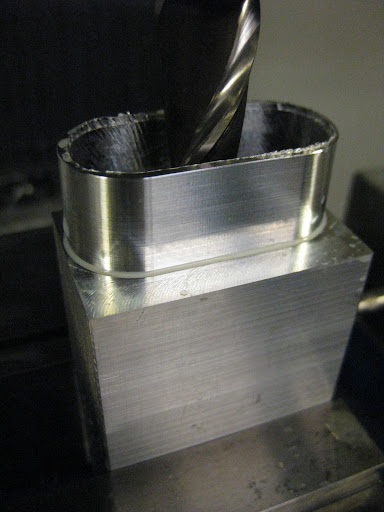

Then the core was roughed out with a 5/8 end mill four inches long;

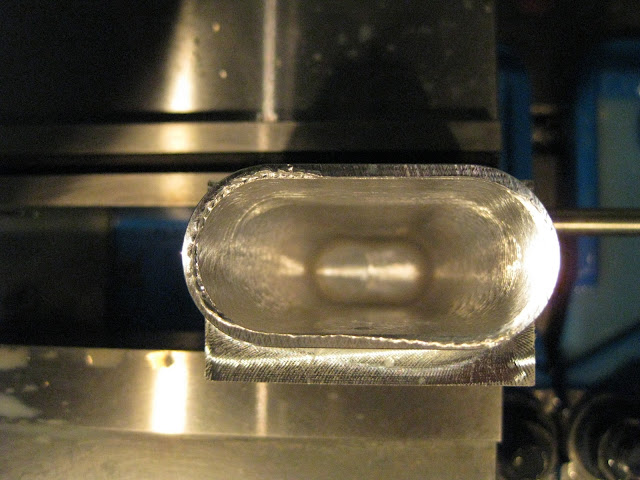

And finished with a ball nose;

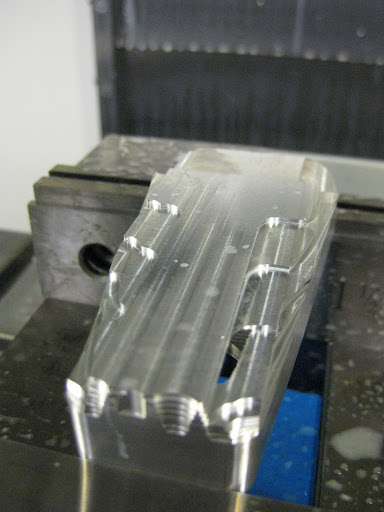

The part was turned on its side and a probe was used to pick up the datum;

[ame]http://www.youtube.com/watch?v=h14iA5FykZI[/ame]

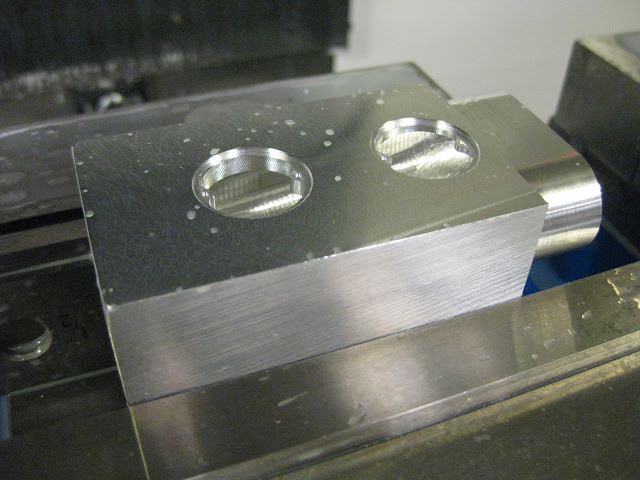

Then the mounting counter bores were machined,

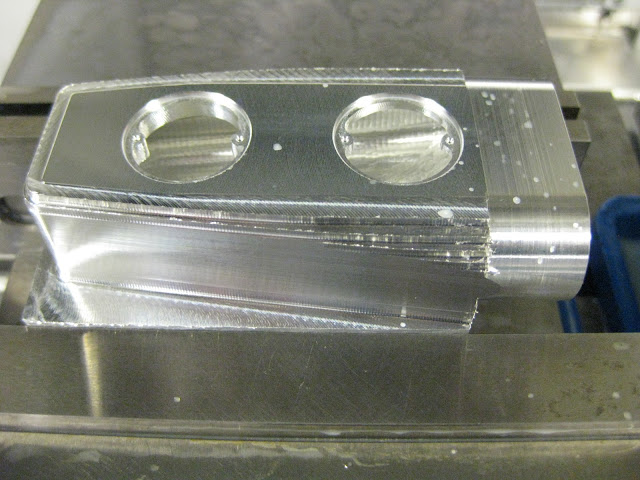

Outer contours roughed out;

[ame]http://www.youtube.com/watch?v=W2L3jQUKQEA[/ame]

And finished, again with a ball nose.

[ame]http://www.youtube.com/watch?v=JbAJAq1BgGs[/ame]

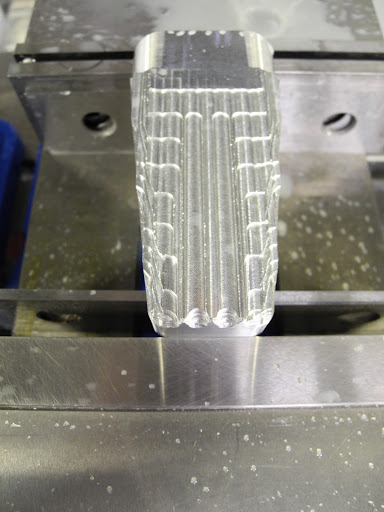

The part was flipped and rotated finished side down;

Then the extra stock was milled off and the "top" details were roughed out;

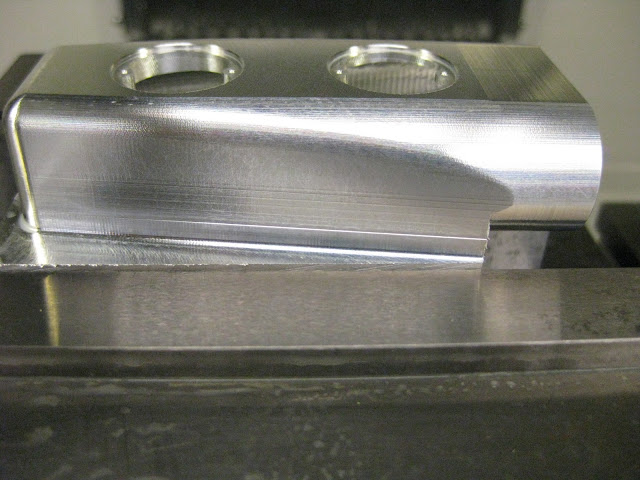

Disaster;

So here we have a finished part, complete with added ventilation at no extra charge!

The bore is flat on the bottom and tapers down toward the back on the top. When I offset the origin for the first operation I left the extra stock on the wrong side.

Oh well the second one is always quicker than the first. I just hope this isn't an omen for things to come..