- Joined

- Dec 14, 2007

- Messages

- 1,181

- Reaction score

- 31

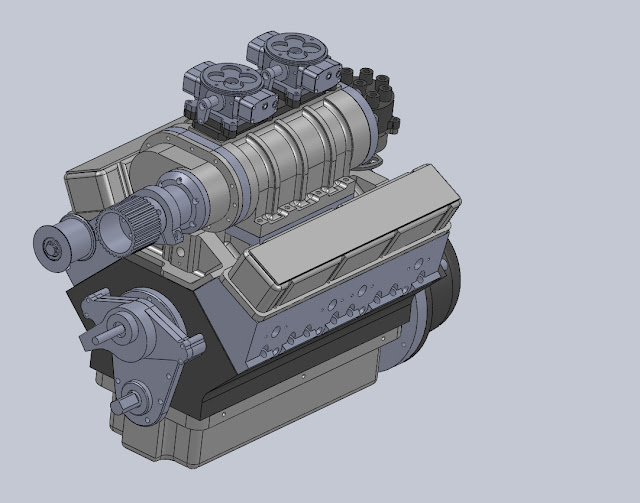

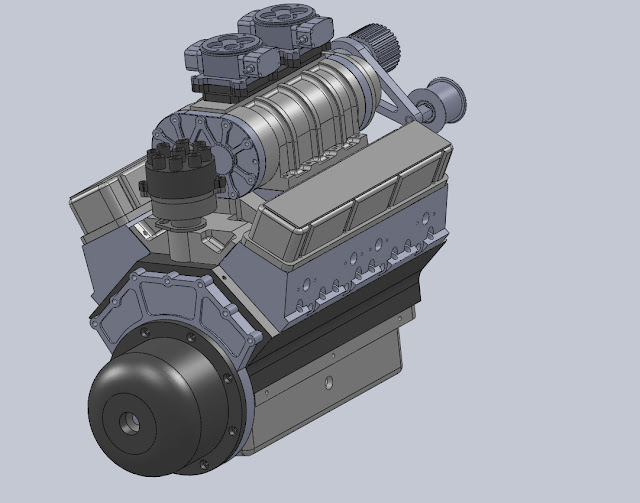

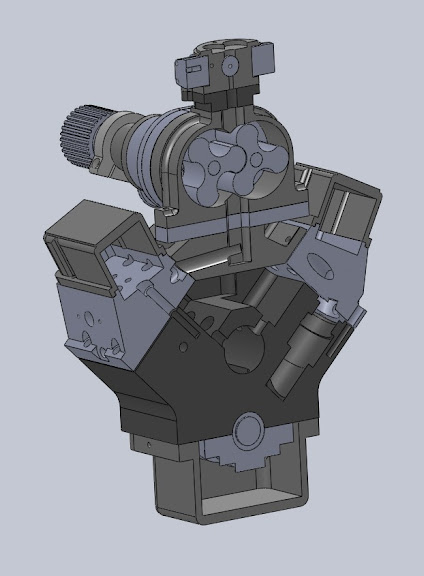

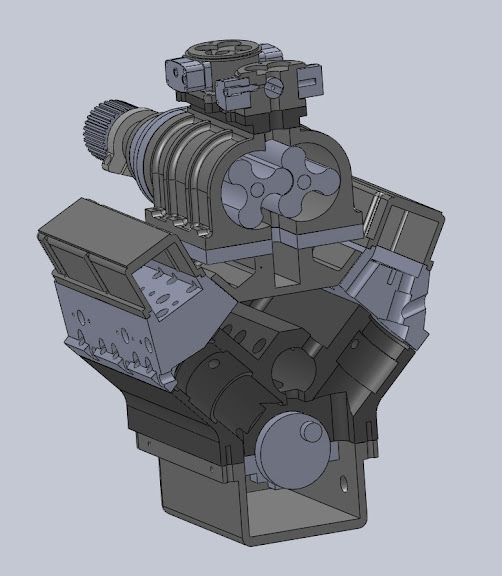

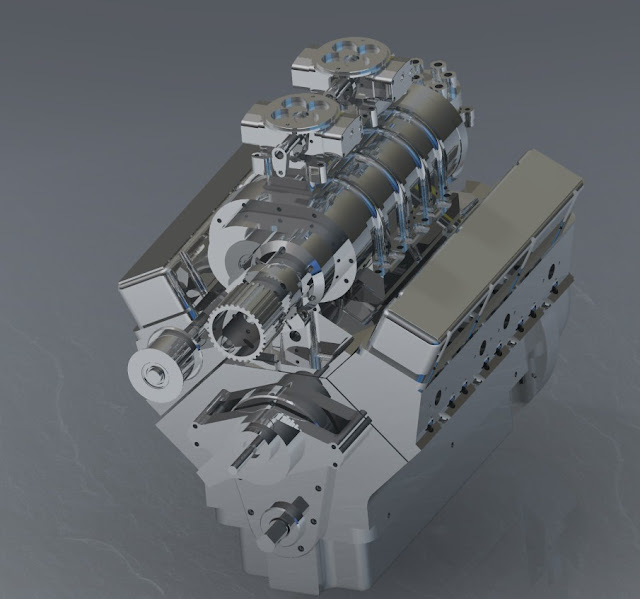

If I ever get around to making some chips for this beauty, I will change the title of this thread.

For now this is where I am at. I have quite a few hours invested in the computer modeling which will pay big dividends when it comes time to make some parts. It also helps me visualize the machining steps and verify the fits of the components. It's nice to make your mistakes on the computer because unfortunately there is no "undo" button in metal. But with this many parts, I know there will be times that I wish there was.