Hi Guys,

Bit of an update on the Loco;

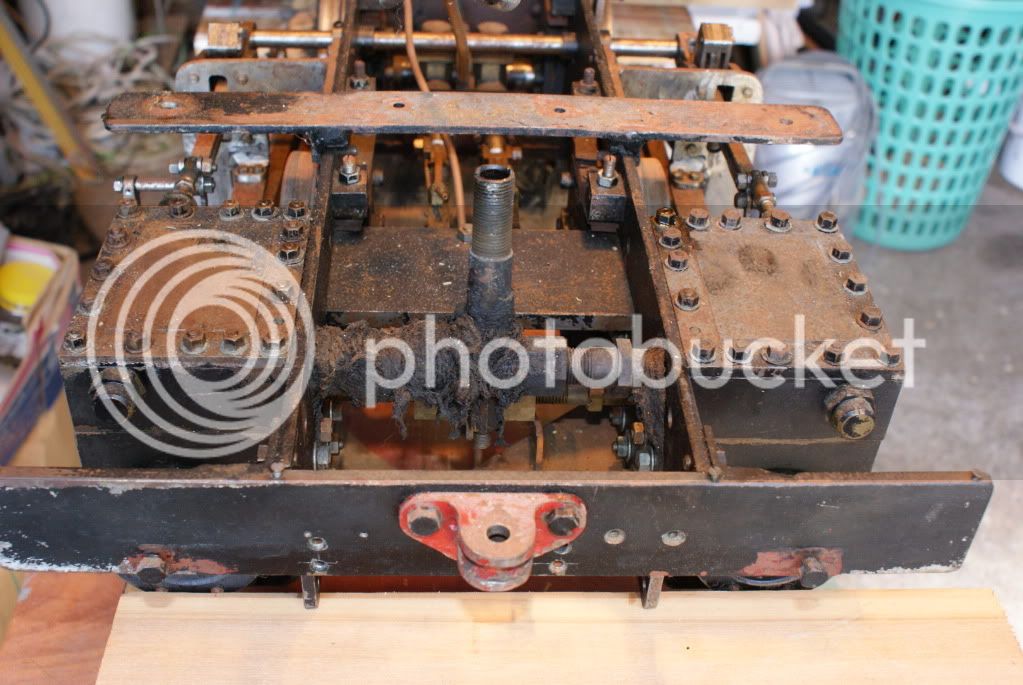

She is now stripped to the Frames, which are now ready for Sandblasting & Painting.

The Cylinders have had their ValveFaces machined to remove the pitting, I needed to take off 0.4mm to achieve this. Just need to Sandblast & Paint, then Lap the Faces and they are ready to go.

The SteamChest Glands and Valve Rods are so worn that replacement is needed for both Items.

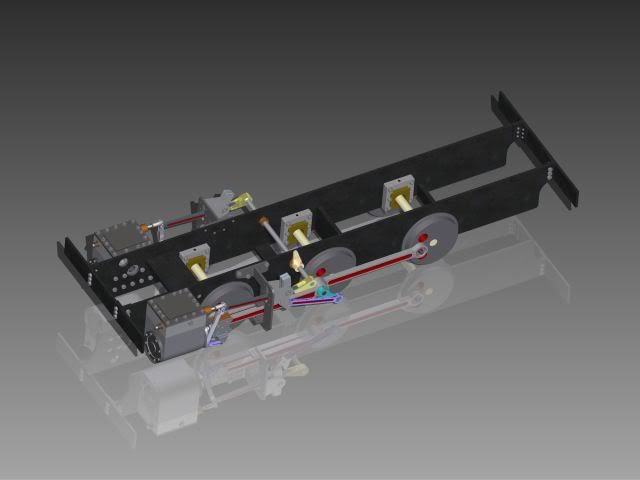

I had a play with the Axleboxes the other day.

Because of the excess play between the Axleboxes & Horns, I've decided to skim the inside of the Axleboxes 1mm and fit Gunmetal Shims, machined to fit.

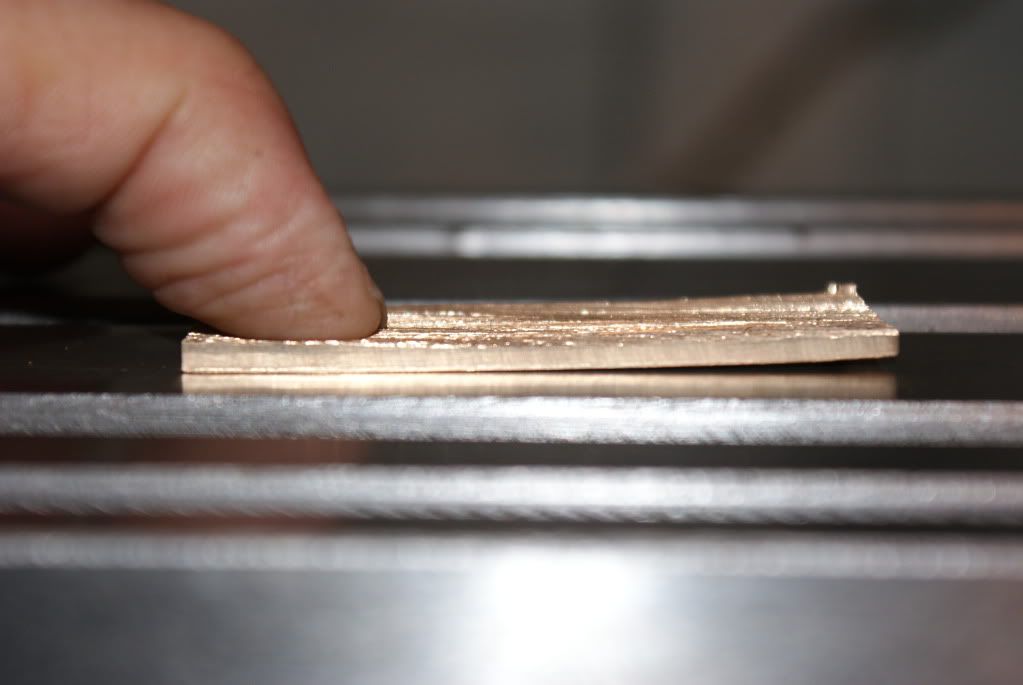

As I dont have any Gunmetal or PhosBronze Strip for the Shims, I decided to make some.

I was given some Bar Ends of 25mmdia Gunmetal the other day, and machined them to 22mm width to suit the width of the axleboxes. I then machined one face flat and hacksawed a 2mm strip off it.

What I ended up with, was this . . . ???

Every Strip I cut, ended up with a distinct curve in it, presumably because of the internal stresses in the bar Stock?

So, I now need to buy :

some flat Barstock to achieve this part of the rebuild.

later . . . .

Murray.