rustyknife

Well-Known Member

- Joined

- Mar 5, 2011

- Messages

- 107

- Reaction score

- 1

Ok....so I thought I knew what I was doing, till I set up my chunk of metal to cut. It became obvious after scratching my head for two hours that I do not.

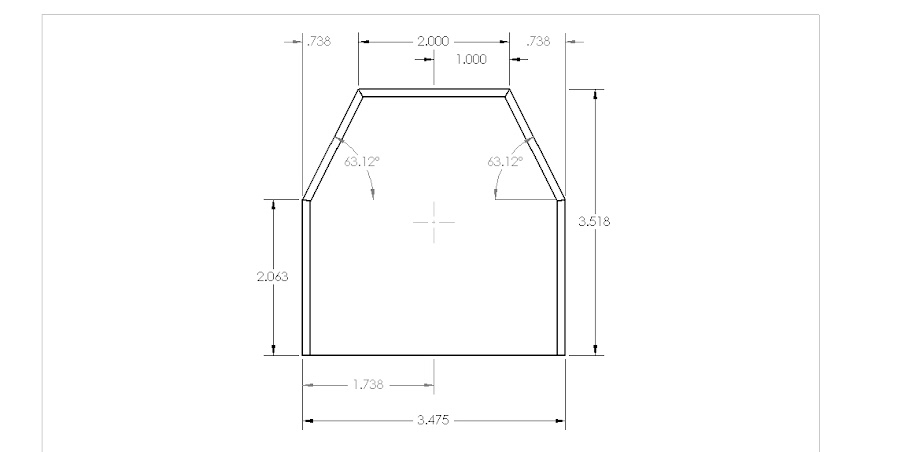

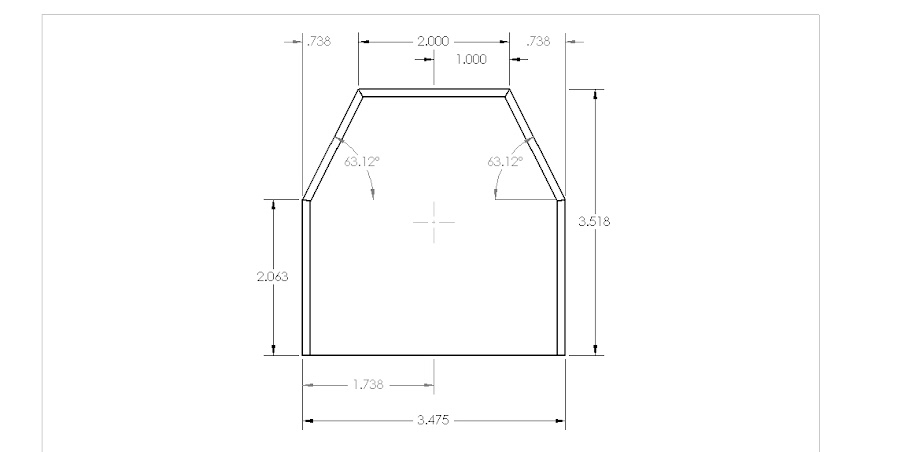

Here is the scenario. I want to shape my flywheel post for my elbow engine. Its a piece of aluminum thats 3.518" tall by 3.475" wide. I want to whittle off the top edges like so.

The 2.063 is the height of the holes for the cylinder and air holes, which definately is not in the center.

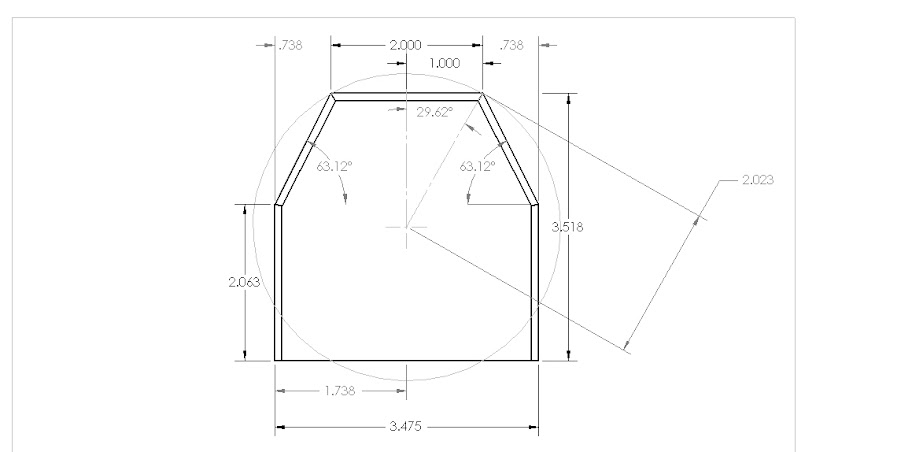

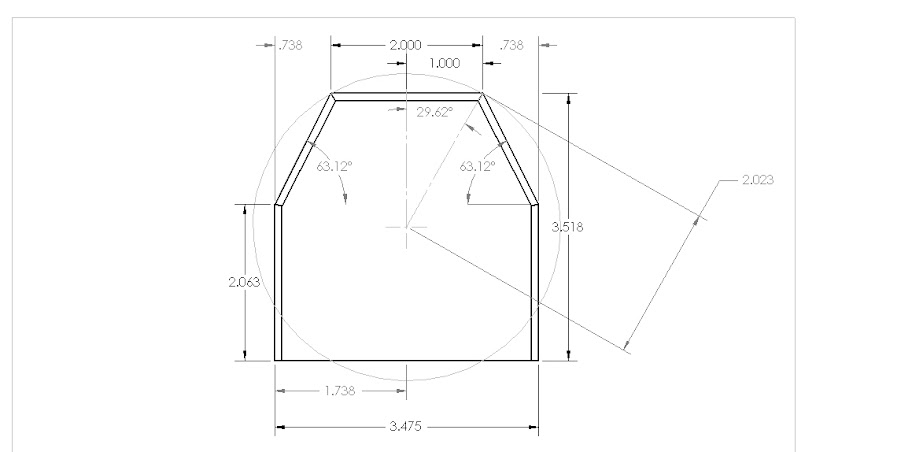

I thought it was going to simple, throw chunk of metal on rotary table rotate the desired degrees and cut front to back. Till I realized that when I indexed my .738 and rotated the table, that I wasn't indexed anymore. Grrr...

Maybe I am making this too complicated....I made a reference circle but I'm not sure if that helping me or not...I'm starting to feel incredibly confused.

How do I get this thing indexed so that I can get my angles cut right on both sides?

Any help would be greatly appreciated.

Regards,

Eric

Here is the scenario. I want to shape my flywheel post for my elbow engine. Its a piece of aluminum thats 3.518" tall by 3.475" wide. I want to whittle off the top edges like so.

The 2.063 is the height of the holes for the cylinder and air holes, which definately is not in the center.

I thought it was going to simple, throw chunk of metal on rotary table rotate the desired degrees and cut front to back. Till I realized that when I indexed my .738 and rotated the table, that I wasn't indexed anymore. Grrr...

Maybe I am making this too complicated....I made a reference circle but I'm not sure if that helping me or not...I'm starting to feel incredibly confused.

How do I get this thing indexed so that I can get my angles cut right on both sides?

Any help would be greatly appreciated.

Regards,

Eric