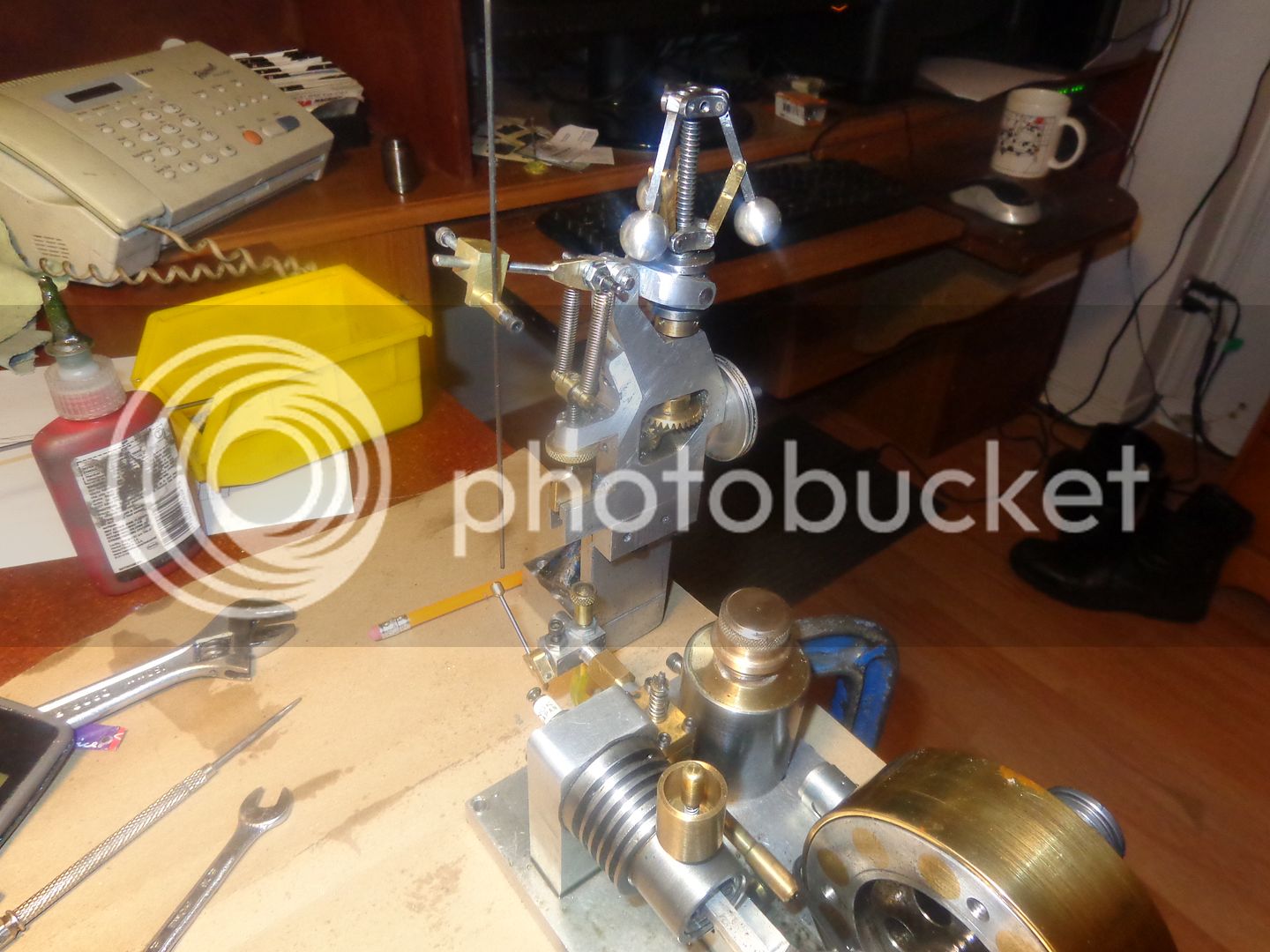

Things are progressing well. I made an executive decision this morning that it was just too bitterly cold out in my main garage where I usually test my engines, so the governor and the Webster were moved in to my engineering reference table where it is toasty and warm. I thought it would be clever to make the governor arm from 1/8" diameter cold rolled steel, with a sliding adjustable block on it. That lets me change the length from the governor arm pivot out out whatever I need the linkage attachment point to be, very simply. Then I decided it would also be nice to be able to adjust the length of the 1/16" diameter link between the governor arm and the carburetor arm, so another small round addition with set screw was added. I lied in the last post where I said the welding rod which I would make the link from was 2 mm. It isn't. Actually, it is 1/16" diameter. I thought it looked a bit "fat" in the solid model, but I didn't go out to the garage to check. Now, onward to build a new carburetor arm for the other end of the "link" to attach to.