You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hit me - Miss me?

- Thread starter Maryak

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Maryak

Well-Known Member

- Joined

- Sep 12, 2008

- Messages

- 4,990

- Reaction score

- 77

Jack B,

Thanks for the kind words and continued support. :bow:

Today I was left in peace and I managed to get the cam profiled. As fully paid up member of, "Gerry and the Hat Tricks," it required all my concentration not to lose my place working round the profile in 2 deg increments. :

The cam blank OD

Ready for transfer to the mill.

Half way now it's time to change hands and go back the other way. ;D

The profiling is complete - All it needs now is parting off, smoothing off, and voila

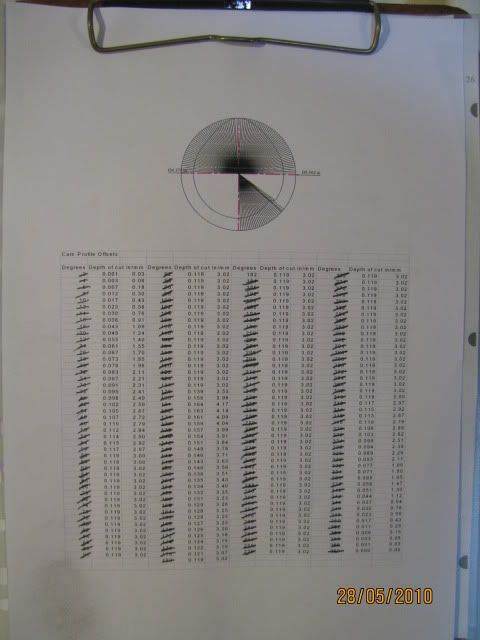

My idiots guide to profiling offsets - derived using Turbocad

Avagoodweekend ;D

Best Regards

Bob

Thanks for the kind words and continued support. :bow:

Today I was left in peace and I managed to get the cam profiled. As fully paid up member of, "Gerry and the Hat Tricks," it required all my concentration not to lose my place working round the profile in 2 deg increments. :

The cam blank OD

Ready for transfer to the mill.

Half way now it's time to change hands and go back the other way. ;D

The profiling is complete - All it needs now is parting off, smoothing off, and voila

My idiots guide to profiling offsets - derived using Turbocad

Avagoodweekend ;D

Best Regards

Bob

arnoldb

Well-Known Member

- Joined

- Apr 8, 2009

- Messages

- 1,792

- Reaction score

- 12

Very nice job on the cam Bob :bow:

Is that profile coordinate table a feature of TurboCad ? - that could be very handy!

;D - I had to smile at your description of your dad's sister. Maybe used them for locking on to the broomstick for sudden acceleration and braking :

Kind regards, Arnold

Is that profile coordinate table a feature of TurboCad ? - that could be very handy!

;D - I had to smile at your description of your dad's sister. Maybe used them for locking on to the broomstick for sudden acceleration and braking :

Kind regards, Arnold

Maryak

Well-Known Member

- Joined

- Sep 12, 2008

- Messages

- 4,990

- Reaction score

- 77

Sam and Phil,

Thanks again for your support. :bow: :bow:

Arnold,

Thanks for stopping by. :bow:

The table was built running Excel in parallel with Turbocad and transferring the offsets from datum measurements. If there is an easier way, I would be very happy to learn about it.

Best Regards

Bob

Thanks again for your support. :bow: :bow:

Arnold,

Thanks for stopping by. :bow:

The table was built running Excel in parallel with Turbocad and transferring the offsets from datum measurements. If there is an easier way, I would be very happy to learn about it.

Best Regards

Bob

Maryak

Well-Known Member

- Joined

- Sep 12, 2008

- Messages

- 4,990

- Reaction score

- 77

Hi Guys,

Not a lot to show for a mornings work but

I finished the cam and the cam/gear shaft is ready for fitting but before I do that I will make the head and then I will have a much better idea of what goes where. :

The finished cam

The cam, gear and shaft.

Best Regards

Bob

Not a lot to show for a mornings work but

I finished the cam and the cam/gear shaft is ready for fitting but before I do that I will make the head and then I will have a much better idea of what goes where. :

The finished cam

The cam, gear and shaft.

Best Regards

Bob

Maryak

Well-Known Member

- Joined

- Sep 12, 2008

- Messages

- 4,990

- Reaction score

- 77

Deanofid said:The finished cam looks good, Bob. It has sort of a notch in it. Can you tell us the purpose of that thing?

Dean

Dean,

Thanks for following along. :bow:

The detente, (notch), is where the points open and close. I don't fully understand it myself yet but I hope all will be revealed as I get a bit more done. :

Gavin & Arnold,

Thanks for your input guys. :bow: :bow:

Best Regards

Bob

- Joined

- Aug 8, 2009

- Messages

- 930

- Reaction score

- 12

Hi Bob. Indeed it is.

Looking good BTW.

-Trout

Looking good BTW.

-Trout

Maryak

Well-Known Member

- Joined

- Sep 12, 2008

- Messages

- 4,990

- Reaction score

- 77

Trout,

Thanks for looking and your help. :bow:

As you may gather, my knowledge of auto electrics is such that you could write it on the back of a postage stamp and still have room for my name and address.

Best Regards

Bob

Thanks for looking and your help. :bow:

As you may gather, my knowledge of auto electrics is such that you could write it on the back of a postage stamp and still have room for my name and address.

Best Regards

Bob

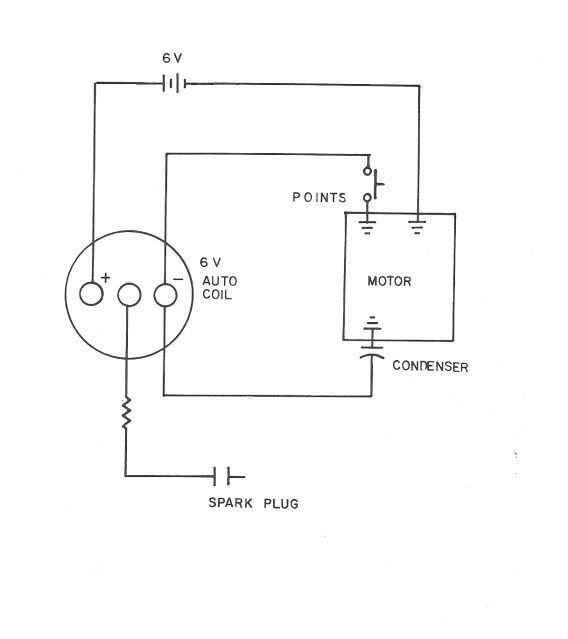

As trout points out, the condensor (capacitor in new speak) is across the points and will suppress arcing. The cam does double duty, driving the valve (which is a smooth ramp up and ramp down action) and driving the points (which needs to be an on/off action) - that would probably explain the notch?

Philjoe5

Well-Known Member

- Joined

- Jul 12, 2007

- Messages

- 1,727

- Reaction score

- 321

Great work Bob. :bow: The discussion about the dual function cam was interesting. When I first started this hobby I thought it was necessary to fully understand the operation and function of all parts before making them. I now realize that there are cases when that becomes much clearer when mating parts have been made and the whole subassembly is sitting in front of you.

Thanks for posting

Cheers,

Phil

Thanks for posting

Cheers,

Phil

Maryak

Well-Known Member

- Joined

- Sep 12, 2008

- Messages

- 4,990

- Reaction score

- 77

Gavin, Phil and Dave,

Thanks for your continued interest and support. :bow: :bow: :bow:

Today seemed like a good day for a head job.................. so I made a start on the head.

I was lucky in finding a piece of round aluminium that would just do the job.

The underside and OD turned.

Set up in the mill for drilling.

The vale recesses and the plug hole.

Next week will see the drilling of the head bolt holes, the drilling jig for the cylinder and last but not least the coolant passages. If I get time I will set up vertically and drill the intake and exhaust passages.

Best Regards

Bob

Thanks for your continued interest and support. :bow: :bow: :bow:

Today seemed like a good day for a head job.................. so I made a start on the head.

I was lucky in finding a piece of round aluminium that would just do the job.

The underside and OD turned.

Set up in the mill for drilling.

The vale recesses and the plug hole.

Next week will see the drilling of the head bolt holes, the drilling jig for the cylinder and last but not least the coolant passages. If I get time I will set up vertically and drill the intake and exhaust passages.

Best Regards

Bob

Similar threads

- Replies

- 6

- Views

- 2K

- Replies

- 19

- Views

- 5K

- Replies

- 13

- Views

- 2K