The physics behind ignition timing is that with certain givens, octane, compression, fuel mixture and combustion chamber design, fuel will burn at a constant rate. Optimally you want the ignition to occur around the time that peak cylinder pressure builds (compression). This can be possibly 20 crank degrees before and after TDC. With an automobile engine idling at anywhere from 600-900 rpm the timing is generally about 10 degrees BTDC. This allows all the fuel to burn and create maximum cylinder pressure (combustion) just as the piston goes past TDC. As the rpm increases the timing advance can go up to 35 degrees BTDC for the same reason. On a model hit

& miss engine that runs quite slowly and the flame front taking less time because of the small displacement it would stand to reason that the timing could be later than conventional full sized engines. Exactly where is a good question. Probably the best answer is wherever your engine runs the best. The one thing that would change this is the type of fuel being used. I don't know the octane of Coleman fuel but the lower the octane the quicker the fuel will burn given a specific compression ratio. With new engines hearing an engine ping because of preignition is almost a thing of the past but if you are familiar with this the cure for it was to go to a higher octane gasoline which burns slower, therefore eliminating the ping. I have a moveable set of points on my Holt engine and when I get the engine set to a certain rpm I move the point lever back and forth and the change in engine performance is quite noticeable, at high and low speeds. That is why these forums are so helpful, someone, somewhere has run into a problem and solved it and with luck is able to pass along their hard earned knowledge.

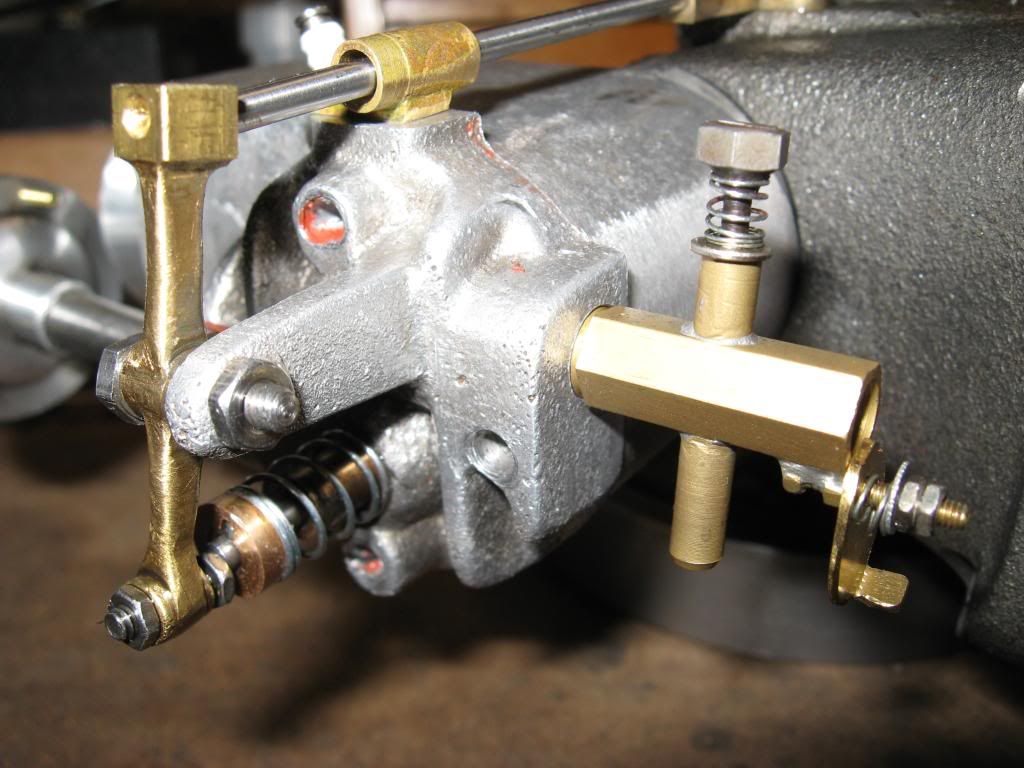

gbritnell