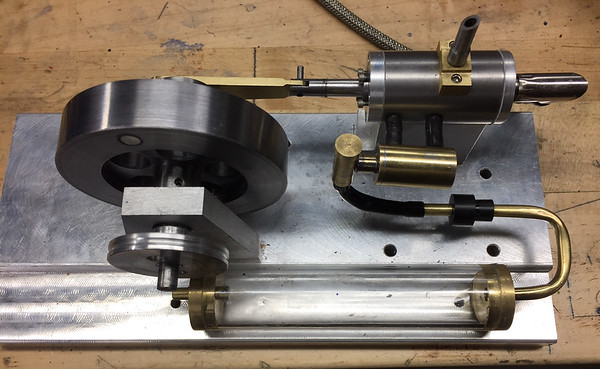

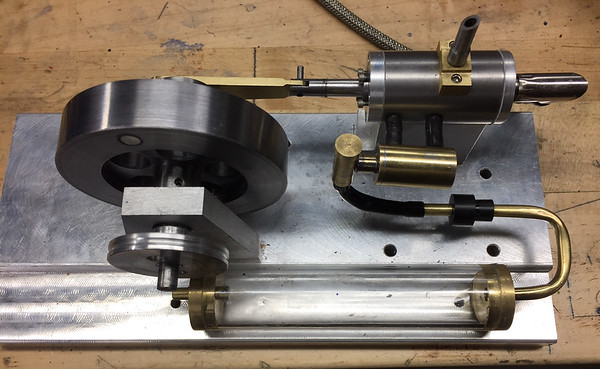

I have completed my version of Jan Ridders 2 stroke design and could use some help getting it running! This is my first engine build so still trying to ramp up.

I adjusted his plans to use materials I already had and converted to inches but maintained all the critical dimensions- piston/bore/ports etc.

So after my first attempts to start got not even a pop (using drill to spin), I discovered that in fact 25 year old coleman fuel does go bad oh:

oh:

With a new bottle of fuel in hand I now can get the engine to pop along nicely with the drill attached, but won't run once I remove.

I took apart the engine and checked compression and port openings/timing and all seem to be working as i think they should.

I am using both an RCEXL CDI ignition, and a homebuilt version with a coil and both give exact same result so I am ruling out ignition problems. Timing I think I have right- i adjusted until I get the most consistent popping and it is pretty much at the recommended 28d before TDC for the CDI unit.

So where do you guys start when facing this? Any usual or likely culprits?

My best guesses now are:

Starved for fuel? Maybe suction stroke under piston not sufficient to pull enough fuel into engine?

One way valve neoprene ball bouncing around too much? Or not enough so blocking fuel intake?

Not enough space at head of cylinder- seems pretty tight up there- maybe too much compression if that is even possible?

The piston and cylinder are both CI and were lapped together so seem to be very good fit, and create lots of suction when I move them.

Appreciate any help!!!

Here is his page describing the engine:

http://ridders.nu/Webpaginas/pagina_tweetakt_puppy/tweetakt_puppy_frameset.htm

I adjusted his plans to use materials I already had and converted to inches but maintained all the critical dimensions- piston/bore/ports etc.

So after my first attempts to start got not even a pop (using drill to spin), I discovered that in fact 25 year old coleman fuel does go bad

With a new bottle of fuel in hand I now can get the engine to pop along nicely with the drill attached, but won't run once I remove.

I took apart the engine and checked compression and port openings/timing and all seem to be working as i think they should.

I am using both an RCEXL CDI ignition, and a homebuilt version with a coil and both give exact same result so I am ruling out ignition problems. Timing I think I have right- i adjusted until I get the most consistent popping and it is pretty much at the recommended 28d before TDC for the CDI unit.

So where do you guys start when facing this? Any usual or likely culprits?

My best guesses now are:

Starved for fuel? Maybe suction stroke under piston not sufficient to pull enough fuel into engine?

One way valve neoprene ball bouncing around too much? Or not enough so blocking fuel intake?

Not enough space at head of cylinder- seems pretty tight up there- maybe too much compression if that is even possible?

The piston and cylinder are both CI and were lapped together so seem to be very good fit, and create lots of suction when I move them.

Appreciate any help!!!

Here is his page describing the engine:

http://ridders.nu/Webpaginas/pagina_tweetakt_puppy/tweetakt_puppy_frameset.htm