Justin_Sane

Member

- Joined

- Aug 14, 2012

- Messages

- 5

- Reaction score

- 1

Hi everyone,

I stumbled across this forum while doing some research on lost wax casting, and took a peek around. This forum seems pretty interesting so I decided to register!

A bit about myself,

I am a machinist/CNC Programmer, I am also a Mechanical Technician Toolmaking, and im currently taking a Robotics technician program.

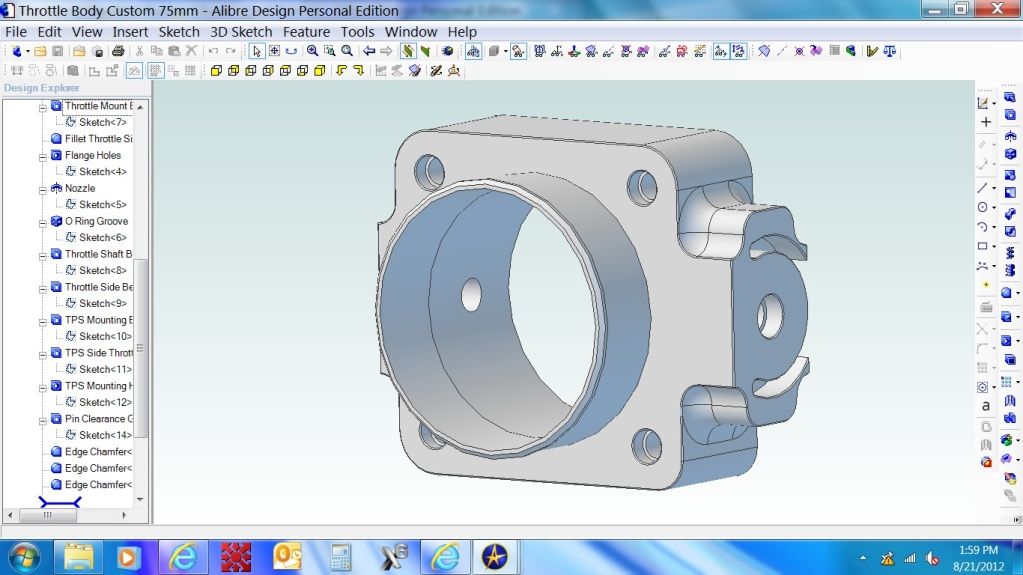

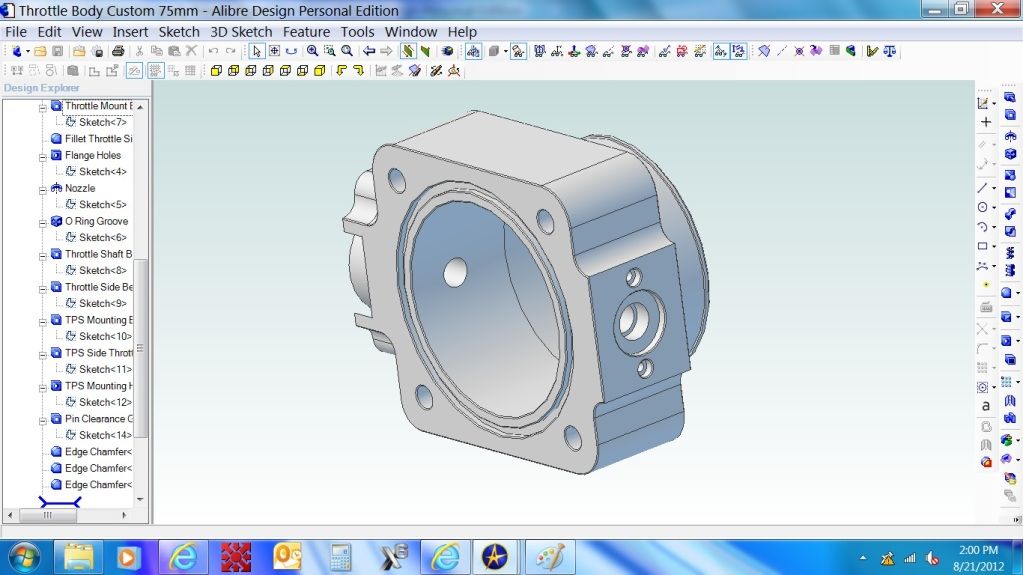

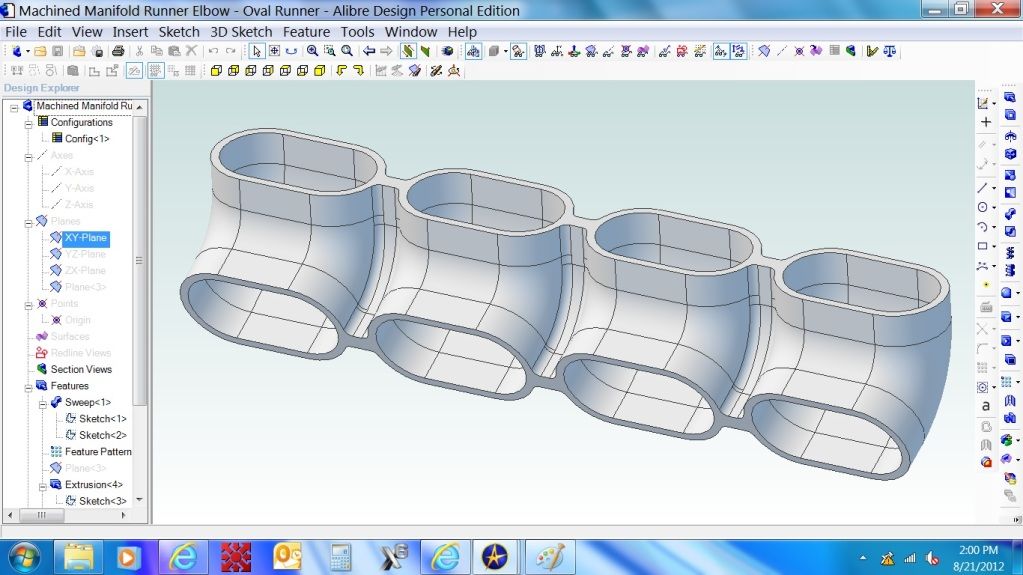

I am currently self employed. My company provides CNC consulting services for the manufacturing industry. I have a fully licenced (3d and multiaxis) current copy of Mastercam. Even though I have the MCX solids module, I also use Alibre 2011 for CAD design.

Personally I have a small taig lathe with 90% of the attachments. I havent used it too much to date, but ive been starting to use it more and more lately. I have also assembled a hobby cnc 4 axis driver, and have plans to convert a small manual machine to cnc. I may just pick up a taig mill for simplicity.

In terms of model engines, I have no experience. It has always been an interest of mine, however I have not gotten into it. With finding this forum, I am looking to change that!

I am glad I found this forum and im looking forward to being a contributing member!

Brandon

I stumbled across this forum while doing some research on lost wax casting, and took a peek around. This forum seems pretty interesting so I decided to register!

A bit about myself,

I am a machinist/CNC Programmer, I am also a Mechanical Technician Toolmaking, and im currently taking a Robotics technician program.

I am currently self employed. My company provides CNC consulting services for the manufacturing industry. I have a fully licenced (3d and multiaxis) current copy of Mastercam. Even though I have the MCX solids module, I also use Alibre 2011 for CAD design.

Personally I have a small taig lathe with 90% of the attachments. I havent used it too much to date, but ive been starting to use it more and more lately. I have also assembled a hobby cnc 4 axis driver, and have plans to convert a small manual machine to cnc. I may just pick up a taig mill for simplicity.

In terms of model engines, I have no experience. It has always been an interest of mine, however I have not gotten into it. With finding this forum, I am looking to change that!

I am glad I found this forum and im looking forward to being a contributing member!

Brandon