just got into some money, and i am now buying a lathe!

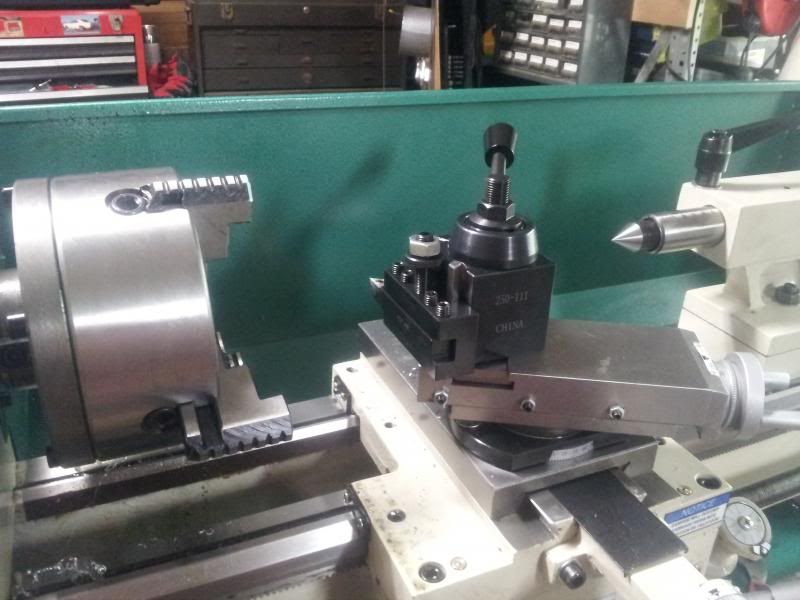

im getting a grizzly 10x22 g0602, im pretty excited about it.

im getting the http://littlemachineshop.com/products/product_view.php?ProductID=3527 tool package.

the live center http://littlemachineshop.com/products/product_view.php?ProductID=3702

ive already got some other tools, so i think i should be set. but im open to suggestions.

im planning to tear it down to the headstock/ bed, using kerosene to clean

for relubing im thinking of mobil 1 red grease, some mobil 1 synthetic, and spray lanolin.

that last part is my question to you guys, do you see anything wrong with coating the bed/ ways with lanolin?

Matt

im getting a grizzly 10x22 g0602, im pretty excited about it.

im getting the http://littlemachineshop.com/products/product_view.php?ProductID=3527 tool package.

the live center http://littlemachineshop.com/products/product_view.php?ProductID=3702

ive already got some other tools, so i think i should be set. but im open to suggestions.

im planning to tear it down to the headstock/ bed, using kerosene to clean

for relubing im thinking of mobil 1 red grease, some mobil 1 synthetic, and spray lanolin.

that last part is my question to you guys, do you see anything wrong with coating the bed/ ways with lanolin?

Matt