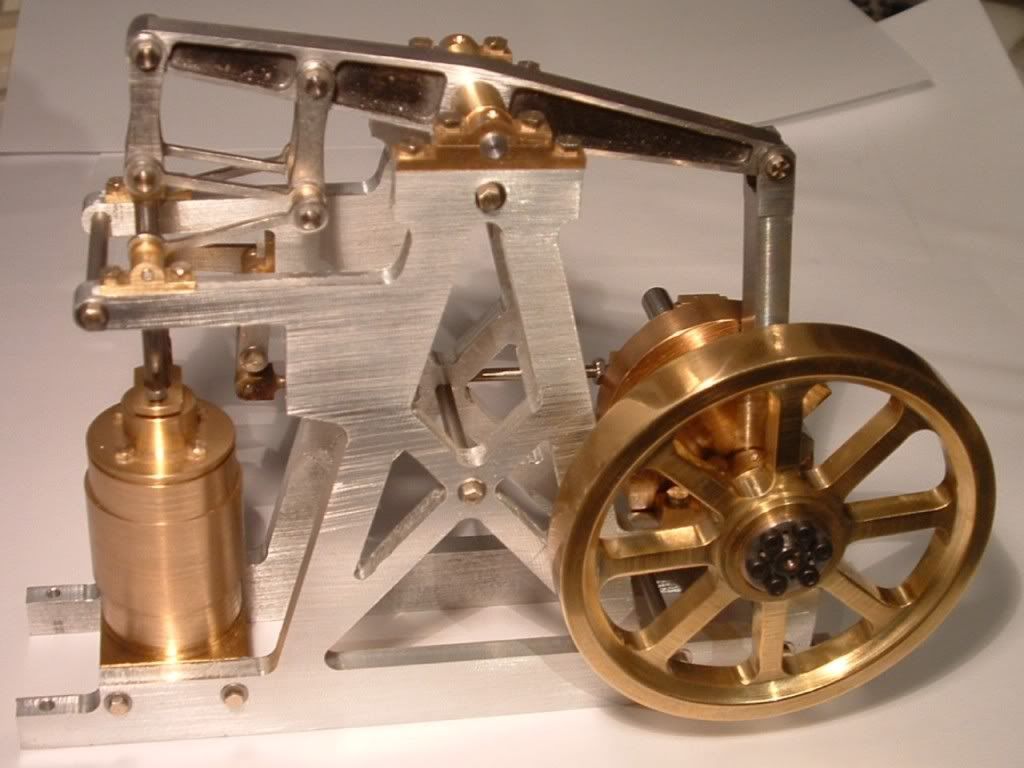

In respone to Stemo's request for a photo of any smaller parts I have made thus far...

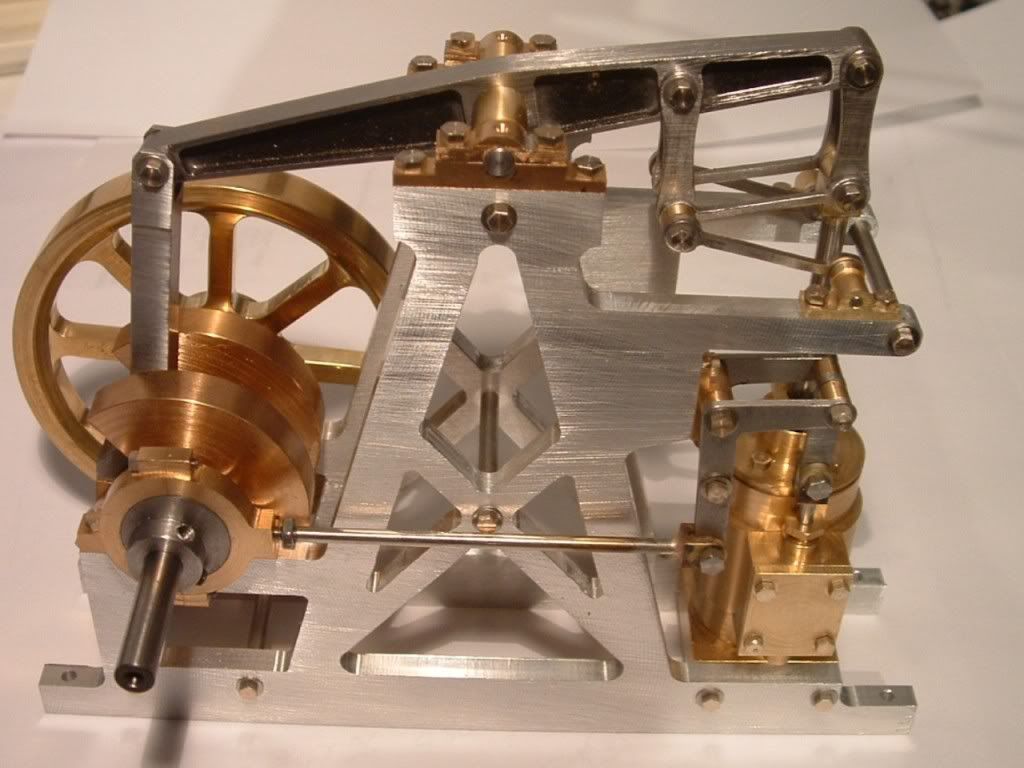

The radii on the bearing caps was cut using TC router bits normally used for woodwork.

I made the small bolts by using cheesehead screws - silver soldering the slot and then grinding on the hexagon using this little fixture below.

I

Ken

The radii on the bearing caps was cut using TC router bits normally used for woodwork.

I made the small bolts by using cheesehead screws - silver soldering the slot and then grinding on the hexagon using this little fixture below.

I

Ken