Mosey

Well-Known Member

Kaleb,

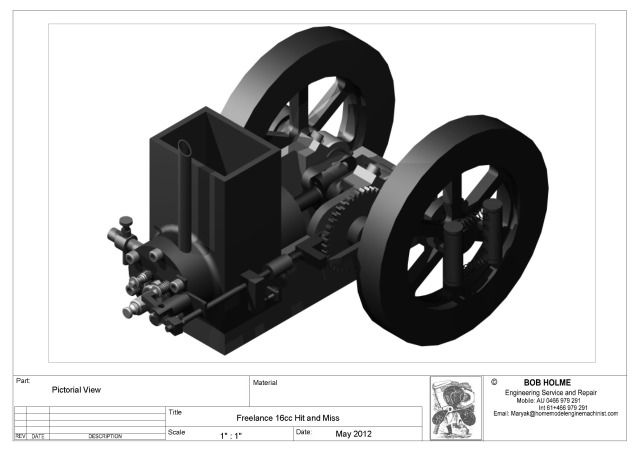

Thanks for your input. Actually, Steve and I are going to try to show some drawings that illustrate the good, the bad, and the ugly, but that will be in a week or 2.

In the meantime, the drawing you show is good, but could be better, and I will make a few, simple suggestions to show what I mean, but that will also be in a day or 2. Please keep in mind that my intention here is to help everyone, not to be a know-it-all. I just hope that someone can find value in what I offer, or if not, there is the delete button. I'm also certain that there are many here who can add their valuable knowledge and experience to this discussion.

Mosey

Thanks for your input. Actually, Steve and I are going to try to show some drawings that illustrate the good, the bad, and the ugly, but that will be in a week or 2.

In the meantime, the drawing you show is good, but could be better, and I will make a few, simple suggestions to show what I mean, but that will also be in a day or 2. Please keep in mind that my intention here is to help everyone, not to be a know-it-all. I just hope that someone can find value in what I offer, or if not, there is the delete button. I'm also certain that there are many here who can add their valuable knowledge and experience to this discussion.

Mosey